Solar energy battery electrode-conducting silver slurry containing micron-size mixed silver powders

A technology for solar cells and conductive silver paste, which is applied to conductive materials, circuits, and electrical components dispersed in non-conductive inorganic materials. The effect of good performance and welding resistance, and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

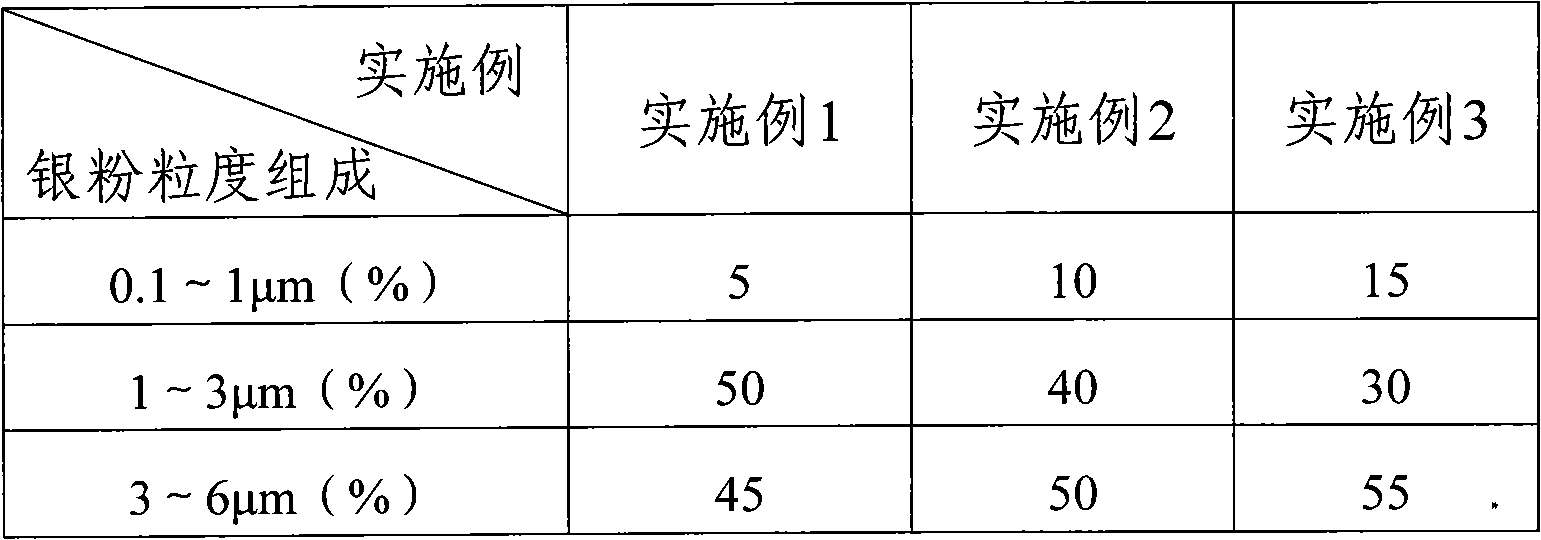

Embodiment 1

[0016] The silver paste includes mixed silver powder, glass powder, and an organic carrier. The mixed silver powder is composed of: 5 wt% of silver powder particles with a particle size of 0.1-1 μm, 50 wt% of silver powder particles with a particle size of 1-3 μm, and 45% of silver powder particles with a particle size of 3 ~6μm silver powder particles.

[0017] Wherein, the mixed silver powder particles are spherical and / or spherical.

[0018] Wherein, the composition of the conductive silver paste includes: 75wt% mixed silver powder, 15wt% glass powder and 5wt% organic vehicle.

[0019] Wherein, the conductive silver paste also includes 5wt% additive, and the additive is MoO 3 .

[0020] Wherein, the organic vehicle contains 55% organic solvent, and the organic vehicle also contains 20% thixotropic regulator, 20% plasticizer and 5% surfactant.

[0021] Wherein, the organic solvent is a composition of terpineol and tributyl citrate, and the weight ratio is 1:1.

[0022] W...

Embodiment 2

[0024] The silver paste includes mixed silver powder, glass powder, and an organic vehicle. The mixed silver powder is composed of: 10 wt% of silver powder particles with a particle size of 0.1-1 μm, 40 wt% of silver powder particles with a particle size of 1-3 μm, and 50% of silver powder particles with a particle size of 3 ~6μm silver powder particles.

[0025] Wherein, the mixed silver powder particles are spherical and / or spherical.

[0026] Wherein, the composition of the conductive silver paste includes: 80wt% mixed silver powder, 7wt% glass powder and 10wt% organic vehicle.

[0027] Wherein, the conductive silver paste also includes an additive of 3wt%, and the additive is Ta 2 o 5 and MoO 3 The composition, the weight ratio is 1:1.

[0028] Wherein, the organic vehicle contains 60% organic solvent, and the organic vehicle also contains 15% thixotropic regulator, 24% plasticizer and 1% surfactant.

[0029] Wherein, the organic solvent is a composition of terpineol ...

Embodiment 3

[0032] The silver paste includes mixed silver powder, glass powder, and an organic carrier. The mixed silver powder is composed of: 15 wt% of silver powder particles with a particle size of 0.1-1 μm, 30 wt% of silver powder particles with a particle size of 1-3 μm, and 55% of silver powder particles with a particle size of 3 ~6μm silver powder particles.

[0033] Wherein, the mixed silver powder particles are spherical and / or spherical.

[0034] Wherein, the composition of the conductive silver paste includes: 85wt% mixed silver powder, 1wt% glass powder and 13wt% organic vehicle.

[0035] Wherein, the conductive silver paste also includes an additive of 1wt%, and the additive is Ta 2 o 5 , V 2 o 5 and MoO 3 The composition, the weight ratio is 1:1:2.

[0036] Wherein, the organic vehicle contains 63% organic solvent, and also contains any one or more of 17% thixotropic regulator, 15% plasticizer and 5% surfactant .

[0037] Wherein, the organic solvent is a compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com