Preparation method for Schottky diode based on core/shell structure silicon nanowire set

A Schottky diode and silicon nanowire technology, applied in the field of semiconductor materials and nano-devices, can solve the problems of harsh preparation conditions, high cost, high repeatability, etc., and achieve the effect of simple preparation method, low cost and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

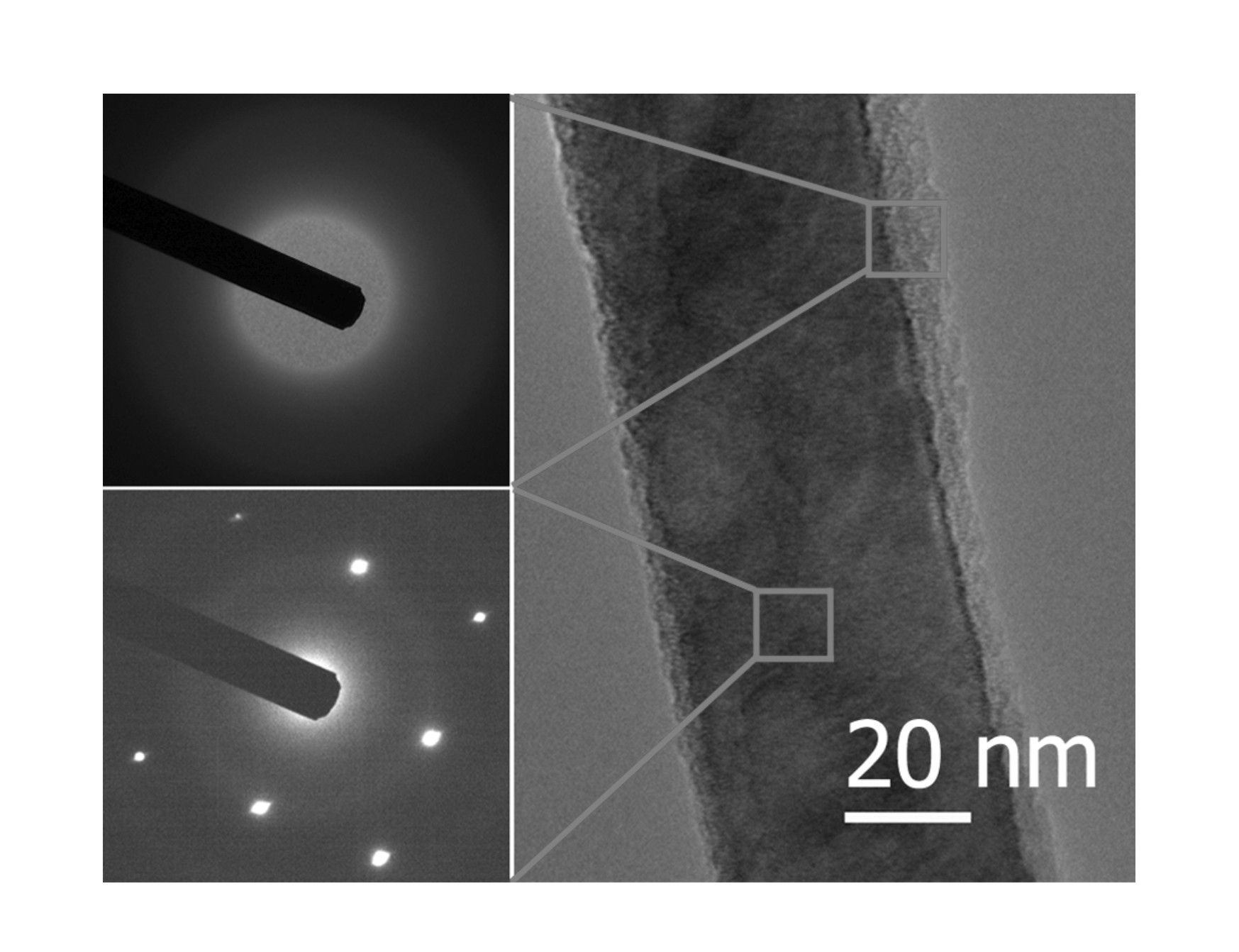

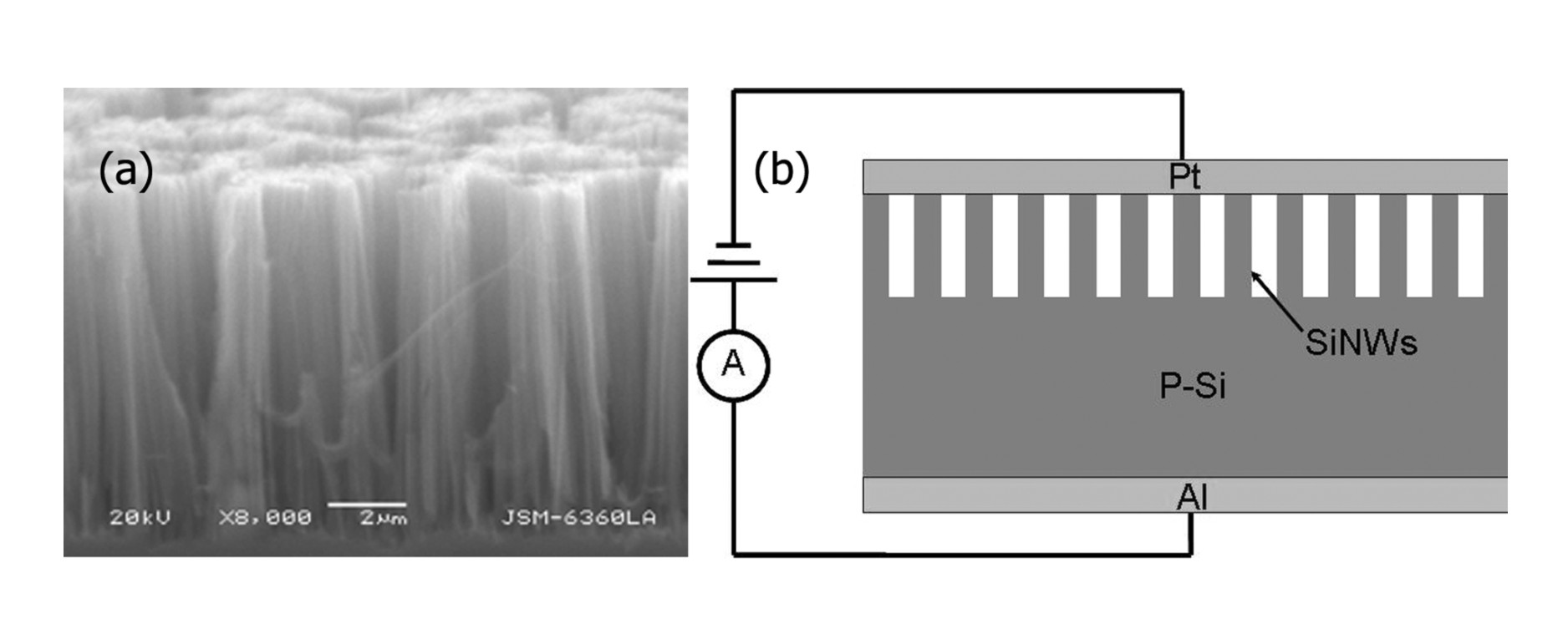

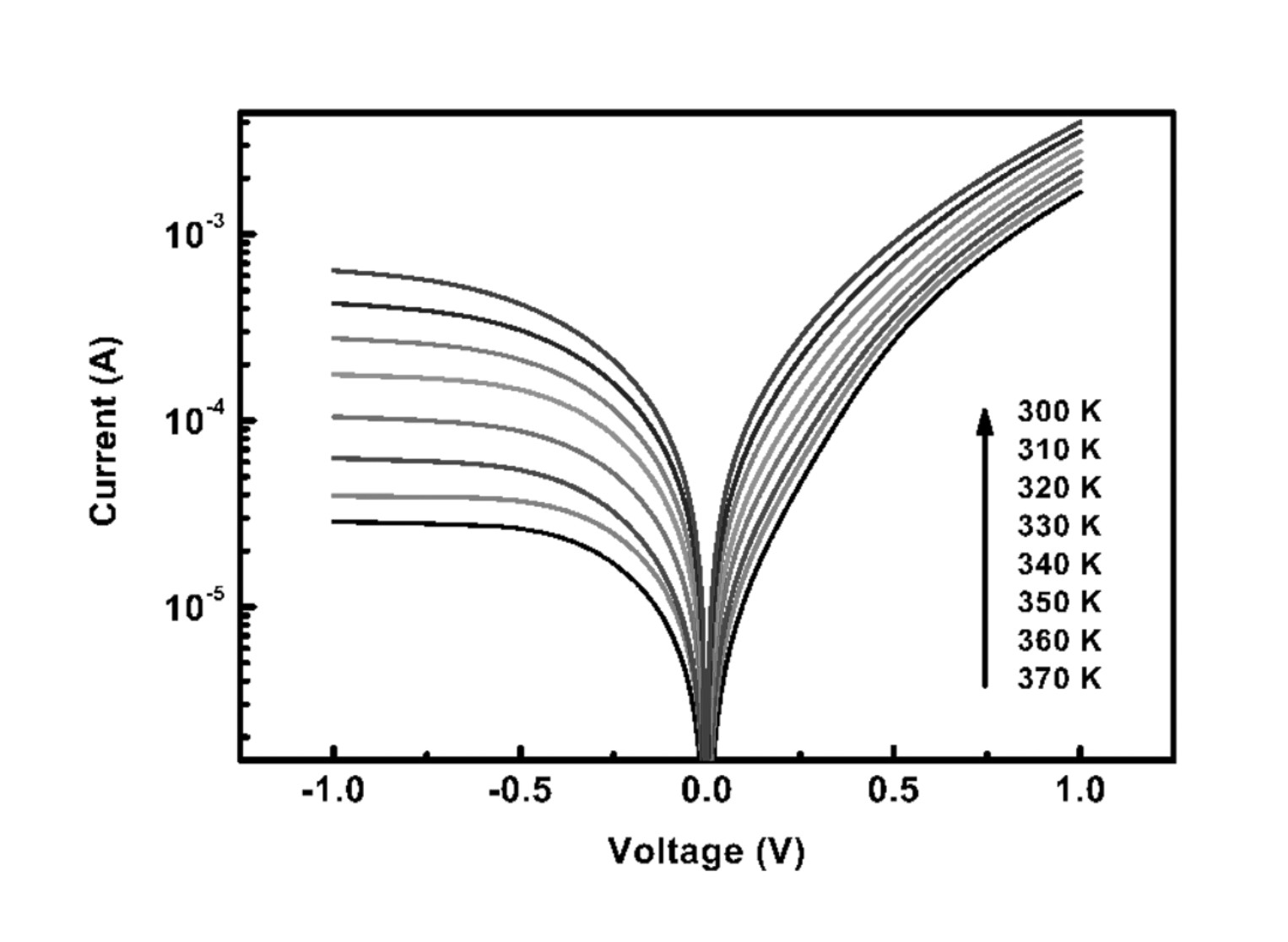

Image

Examples

Embodiment

[0031] 1) Wafer cleaning

[0032] Take a 1cm×1cm silicon wafer (p-type, double-sided polishing, crystal orientation, resistivity 0.1-10Ω·cm), clean the silicon wafer with standard RCA cleaning steps and dry it with nitrogen gas for later use.

[0033] 2) Al back electrode preparation

[0034] Evaporate Al on one side of the silicon wafer by a vacuum evaporation device, and thermally anneal at 450°C for 5 minutes in a nitrogen atmosphere to form a good ohmic contact Al back electrode; spin-coat the Al back electrode surface with photoresist, dry the photoresist, In order to protect the back electrode from being damaged during the preparation of the silicon nanowire by the electroless chemical etching method.

[0035] 3) Preparation of silicon wafer chemical etching solution

[0036] Prepare 25 mmol L -1 AgNO 3 , hydrofluoric acid (40% HF concentration) mixed solution (25 mmol L -1 AgNO 3 and concentration of 40% HF volume ratio (1:1) 200 mL, sonicate to make the mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com