1-methylcyclopropene and chlorine dioxide graded release device and preparation method thereof

A technology of methylcyclopropene and chlorine dioxide is applied in the fields of food preservation, fruit and vegetable preservation, food science, etc., which can solve the problems of insignificant effect, danger of strong acid corrosion, lowering the quality of fruits and vegetables, etc., and achieves convenient transportation and safe use. , Avoid the inconvenience of adding water, and avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

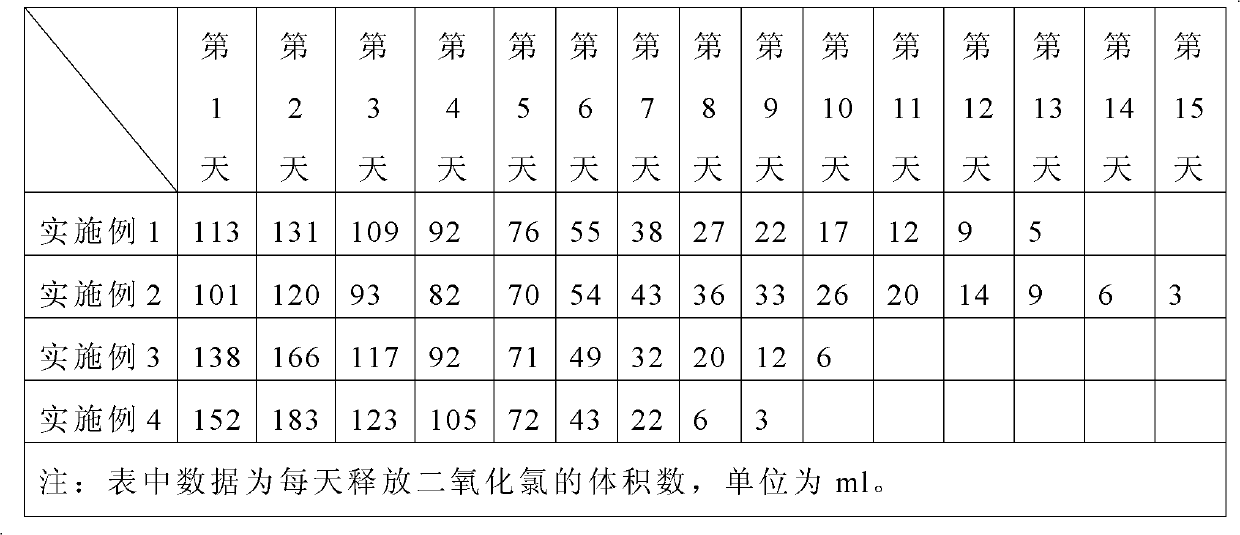

Embodiment 1

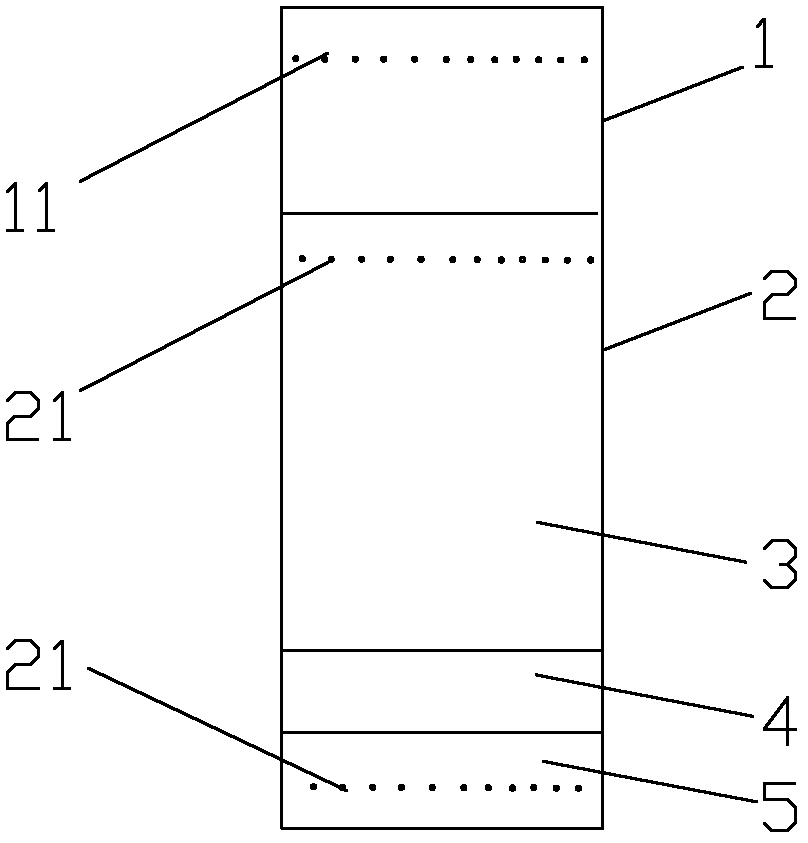

[0028] figure 1 The shown 1-methylcyclopropene and chlorine dioxide graded release device, it comprises medicament and the box body that is used to hold medicament, wherein, medicament comprises by 0.2g commercially available 1-methylcyclopropene sustained release capsule, 1g carbonic acid A 1-methylcyclopropene generating agent uniformly mixed with sodium and 1g of magnesium chloride; 2g of sodium chlorite (ie 0.02mol), 15g of vermiculite with a particle size of 40 mesh, 1.5g of diatomite with a particle size of 60 mesh and 0.5g Chlorine dioxide generator uniformly mixed with calcium silicate with a particle size of 80 mesh; mineral particles uniformly mixed with 2.5g of diatomite with a particle size of 80 mesh and 0.5g of calcium silicate with a particle size of 80 mesh; composed of 2.7g Potassium dihydrogen phosphate (0.02mol) and 5g magnesium chloride are uniformly mixed acidic moisture generator;

[0029] The box body includes an end box body 1 filled with the 1-methylc...

Embodiment 2

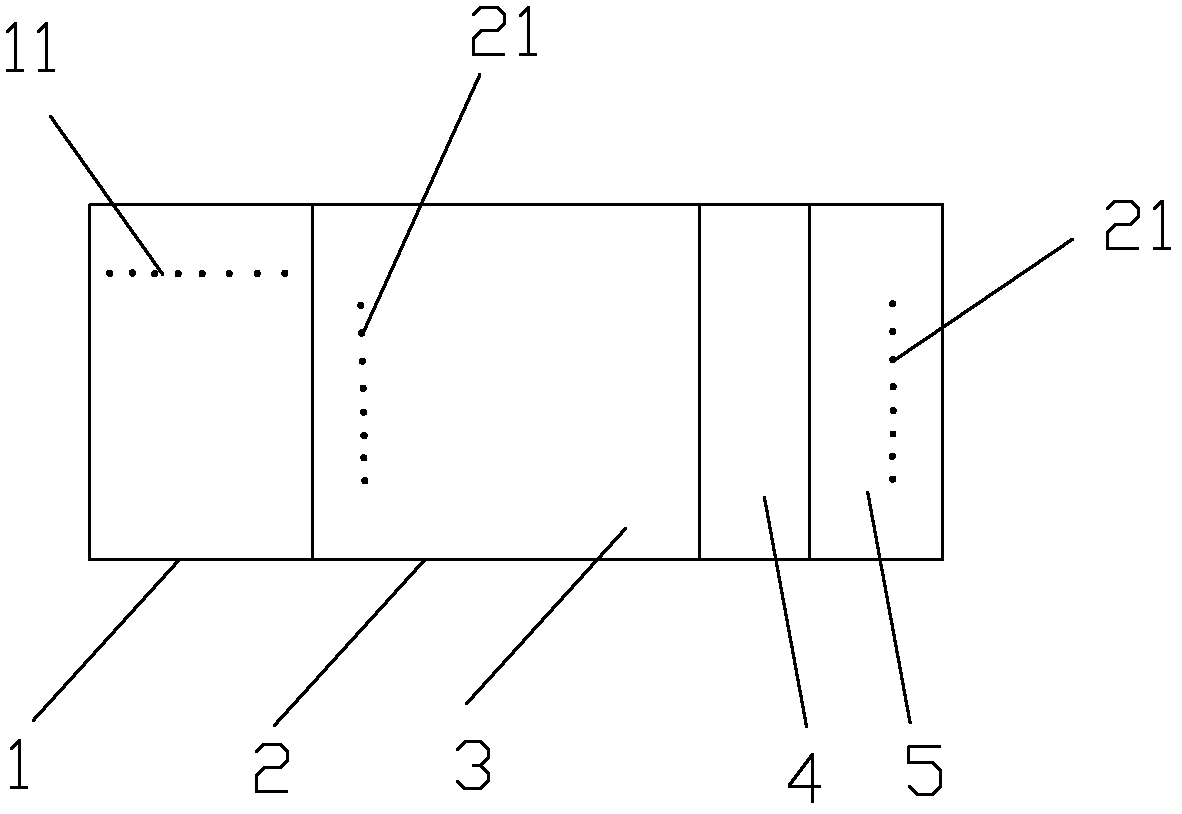

[0031] figure 2 The shown 1-methylcyclopropene and chlorine dioxide graded release device, it comprises medicament and the box body that is used to hold medicament, wherein, medicament comprises by 0.2g commercially available 1-methylcyclopropene sustained release capsule, 1g carbonic acid 1-methylcyclopropene generator uniformly mixed with sodium and 1.5g of magnesium chloride; uniformly mixed with 2g of sodium chlorite (ie 0.02mol), 12g of vermiculite with a particle size of 40 mesh, and 4.5g of bentonite with a particle size of 60 mesh Chlorine dioxide generator; 3.0g particle size is 80 mesh diatomite, 0.7g particle size is 120 mesh calcium silicate uniformly mixed mineral particles; 1.8g oxalic acid (ie 0.02mol) and 2g magnesium chloride, 3g An acidic moisture generator made of uniformly mixed sodium sulfate;

[0032] The box body includes an end box body 1 filled with the 1-methylcyclopropene generator and a combination of chlorine dioxide generator 3, mineral particle...

Embodiment 3

[0034] figure 2 The shown 1-methylcyclopropene and chlorine dioxide graded release device, it comprises medicament and the box body that is used to hold medicament, wherein, medicament comprises by 0.2g commercially available 1-methylcyclopropene sustained release capsule, 2g carbonic acid A 1-methylcyclopropene generating agent uniformly mixed with sodium and 3g of calcium chloride; 2g of sodium chlorite (ie 0.02mol), 10g of vermiculite with a particle size of 40 mesh, 2g of diatomite with a particle size of 60 mesh, 4.5 g particle size is a chlorine dioxide generator uniformly mixed with bentonite of 60 mesh; 1.0 g of perlite powder with a particle size of 80 mesh and 2.5 g of calcium silicate with a particle size of 120 mesh are evenly mixed; mineral particles made of 2 g of citric acid (i.e. 0.01mol) and 2g magnesium chloride, 2g sodium sulfate uniformly mixed acid moisture generating agent;

[0035] The box body includes an end box body 1 filled with the 1-methylcyclopr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com