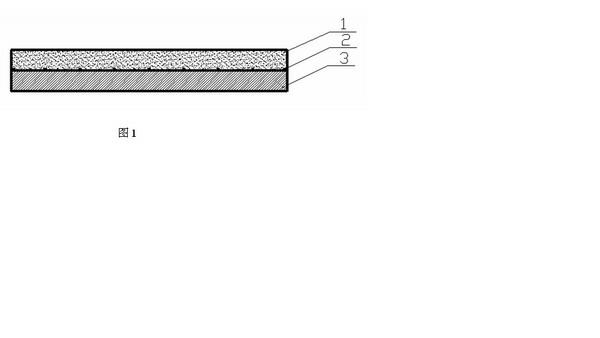

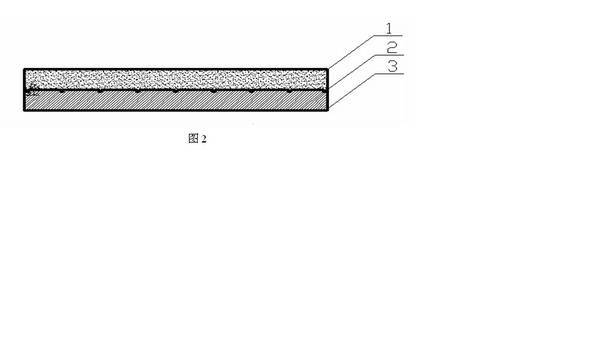

Steel-base polyether-ether-ketone composite plate and manufacturing method thereof

A polyetheretherketone and steel-based polyether technology is applied in engineering plastics and metal composite panels and their preparation, and in the fields of composite panels and their preparation, and can solve the problems of poor corrosion resistance, no wear resistance, fast heat transfer, etc. Achieve the effect of good dimensional stability, good adhesion performance and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dry 65 parts of polyether ether ketone powder before use, and dry it at 150 ° C for 3 hours; the treated polyether ether ketone, 11 parts of PAN carbon fiber, 10 parts of polytetrafluoroethylene, 12 parts of graphite powder, 1 part of silane-based coupling agent KH560 coupling agent, placed in a high mixer and mixed evenly for 25 minutes to obtain fiber-reinforced polyether ether ketone powder;

[0024] (2) Take 580×200×12mm No. 45 steel plate welded with 5mm diameter metal twisted steel and place it on the mold. The mold needs to be pretreated at 150°C for 20 minutes before use, and weigh the fiber-reinforced polyether ether ketone powder 2 kg of material, put on the steel plate, assemble the mold, pressurize to 500 Kg / cm 2 , hold the pressure for 4 minutes, heat the mold in an oven at 390°C for 9 hours, quickly take out the mold and place it on a press, cool it for 4 minutes, and pressurize to 800 Kg / cm 2 , keep the pressure for 25 minutes, when the temperature d...

Embodiment 2

[0026] (1) Dry 68 parts of polyether ether ketone powder before use, and dry it at 170 ° C for 2 hours; the treated polyether ether ketone, 10 parts of PAN carbon fiber, 8 parts of polytetrafluoroethylene, 13 parts of graphite powder, 1.6 parts of silane-based KH570 coupling agent, placed in a high mixer and mixed evenly for 25 minutes to obtain fiber-reinforced polyether ether ketone powder;

[0027] (2) Take a 580×200×12mm dovetail Q235 steel plate machined with a width of 10mm, a depth of 3mm, and 60°, and place it on the mold. It is said that the mold needs to be pretreated at 150°C for 10 minutes before use. 2.5 kg of ether ether ketone powder is placed on the steel plate, the mold is assembled, and the pressure is increased to 600 Kg / cm 2 , hold the pressure for 2 minutes, heat the mold in a 400°C oven for 7 hours, quickly take out the mold and place it on the press, cool it for 4 minutes, and pressurize to 1000 Kg / cm 2 , keep the pressure for 35 minutes, when the tempe...

Embodiment 3

[0029] (1) Dry 70 parts of polyether ether ketone powder before use, and dry it at 160 ° C for 4 hours; the treated polyether ether ketone, 12 parts of PAN carbon fiber, 9 parts of polytetrafluoroethylene, 13 parts of graphite powder, 0.5 part of silane-based KH550 coupling agent, placed in a high mixer and mixed evenly for 30 minutes to obtain fiber-reinforced polyether ether ketone powder;

[0030] (2) Take the 450×120×15mm top machined 10mm wide, 3mm deep, 60° dovetail groove No. 20 steel plate and place it on the mold. The mold needs to be pretreated at 150°C for 30 minutes before use, and the fiber reinforced 1.5 kg of polyether ether ketone powder is placed on the steel plate, the mold is assembled, and the pressure is increased to 400 Kg / cm 2 , hold the pressure for 5 minutes, heat the mold in a 400°C oven for 8 hours, quickly take out the mold and place it on the press, cool it for 5 minutes, and pressurize to 700Kg / cm 2 , keep the pressure for 25 minutes, when the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com