Method for photocatalysis of water by adopting nanometer porous titanium oxide film

A titanium oxide film and nanoporous technology, applied in the field of neutral activated water, can solve the problems of easy pollution, refinement, and high operating costs, and achieve the effects of eliminating harmful pollutants, improving catalytic activity, and delicious meat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

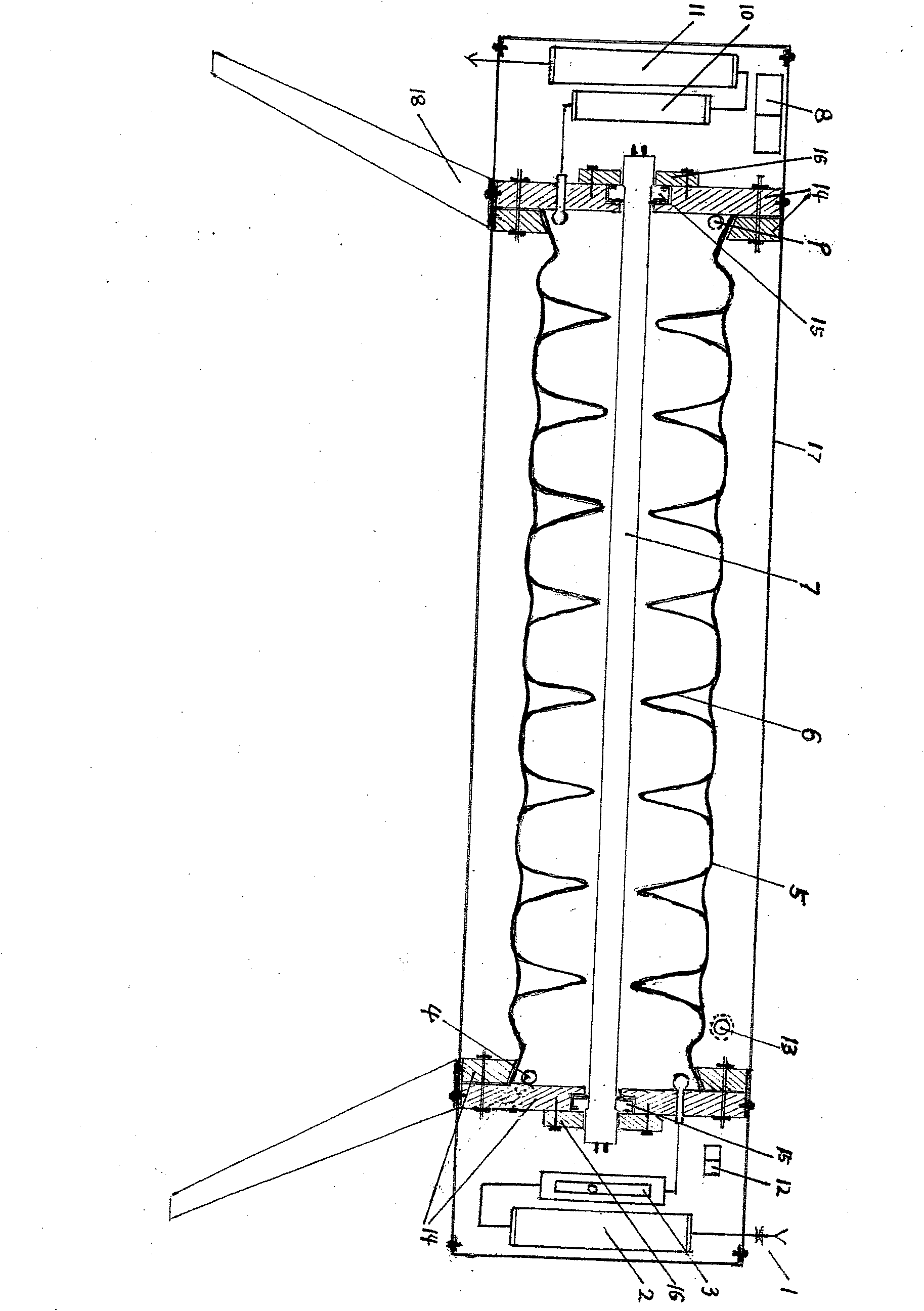

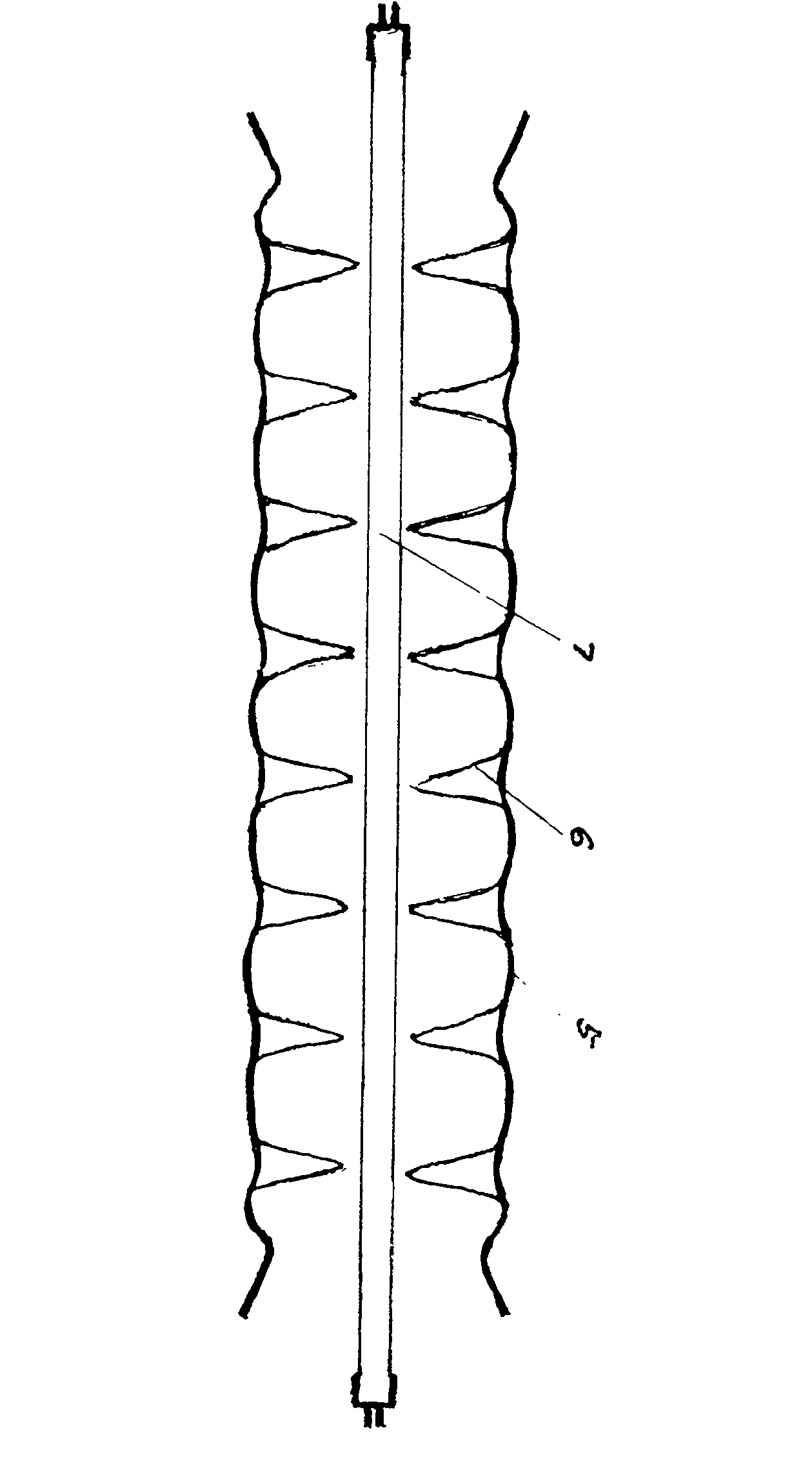

[0025] Hereinafter, preferred embodiments of the patent of the present invention will be described in detail with reference to the accompanying drawings.

[0026] Such as figure 1 and figure 2 As shown, put each component in place according to the designed position; then put the valve 1, filter 2, flow meter 3, glass tube 5, O-shaped diverter ring 4, O-shaped collector ring 9, valve flange plate 14 (4 pieces ), O-type sealing ring 15 (2 pieces), sealing ring cover 16 (2 pieces), ultraviolet lamp tube 7, shell 17, pin 18 and work lampshade 13, are connected with bolt; Then ultraviolet lamp tube 7, ballast Connect the device 8, the power switch 12 and the power cord; finally, connect the following components with a φ12 transparent rubber tube, and lock the tube head with an O-shaped fastening ring. The connection sequence is as follows:

[0027]

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com