Low-heat-conduction silicon mullite brick and preparation method thereof

A silicon molybdenum brick and low thermal conductivity technology, which is applied in the field of low thermal conductivity silica molybdenum brick and its preparation, can solve the problems of high equipment temperature and high thermal conductivity of silica molybdenum brick, and achieve light bulk density, scientific and simple preparation method, and thermal stability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

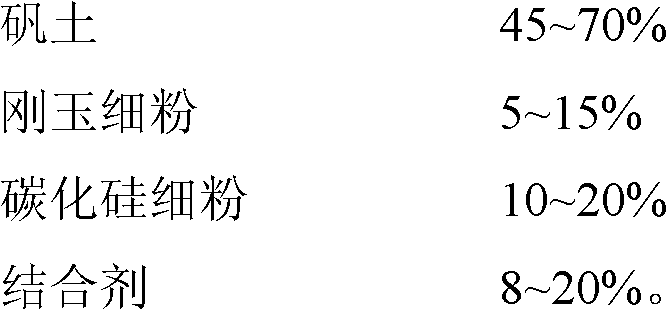

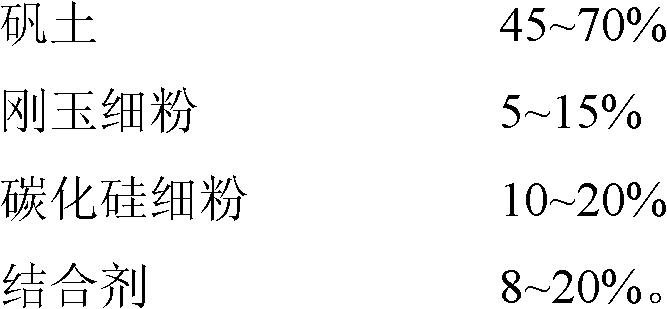

Method used

Image

Examples

Embodiment 1

[0017] Take 5% of 3-5mm bauxite (unit is percentage by weight, the same below), 35% of 1-3mm bauxite, 15% < 1mm bauxite, 15% of corundum fine powder, 20% of silicon carbide fine powder and 10% binder, pour into the mixer and mix the dry material for 5 minutes, add tap water with 1% of the total weight of raw materials and stir for 10 minutes, and then trap the material for 3 hours, and make adobe by a press, and put the adobe at 180 degrees Bake, bake for 8 hours, then send it into a tunnel kiln and burn for 48 hours at 1000 degrees; wherein the preparation method of the binder is: 5 parts by weight of aluminum orthophosphate, 1 part of oxalic acid, 1 part 1 part of mullite fine powder and 1 part of methyl cellulose are crushed, mixed for 8 minutes, then added with 5% water of the total mass of the mixture, and stirred for 5 minutes.

Embodiment 2

[0019] Take 8% of 3-5mm bauxite (unit is percentage by weight, the same below), 32% of 1-3mm bauxite, 16%<1mm bauxite, 12% of corundum fine powder, 18% of silicon carbide fine powder and 18% binder, pour into the mixer and mix the dry material for 6 minutes, add tap water with 2% of the total weight of the raw materials and stir for 12 minutes, and then trap the material for 3 hours, and make bricks through a press, and put the bricks at 190 degrees Bake, bake for 10 hours, then send it into a tunnel kiln and burn for 52 hours at 1050 degrees; wherein the binder preparation method is: 6 parts by weight of aluminum orthophosphate, 2 parts of oxalic acid, 13 1 part of mullite fine powder and 2 parts of methyl cellulose are crushed, mixed for 9 minutes, mixed with 6% water of the total mass of the mixture, and stirred for 6 minutes.

Embodiment 3

[0021] Take 10% of 3-5mm bauxite (unit is percentage by weight, the same below), 30% of 1-3mm bauxite, 17%<1mm bauxite, 10% of corundum fine powder, 13% of silicon carbide fine powder and 20% binder, pour into the mixer and mix the dry material for 9 minutes, add tap water with 3% of the total weight of the raw materials and stir for 15 minutes, and then trap the material for 4 hours, and make adobe by a press, and put the adobe at 200 degrees Bake, bake for 12 hours, then send it into a tunnel kiln and burn for 54 hours at 1100 degrees; wherein the preparation method of the binder is: 9 parts by weight of aluminum orthophosphate, 6 parts of oxalic acid, 23 One part of mullite fine powder and three parts of methyl cellulose were crushed, mixed for 10 minutes, then added with 7% water of the total mass of the mixture, and stirred for 8 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com