Sound absorbing material quick in onsite construction and method for preparing sound absorbing material

A sound-absorbing material and fast technology, applied in the direction of sound insulation, building components, floors, etc., can solve the problems of affecting the sound-absorbing effect, large transportation volume, and troublesome construction, and achieve the effect of good sound-absorbing effect, reducing inconvenience and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to the technical scheme of the present invention, a sound-absorbing material for rapid on-site construction has been prepared. Its components are 50 parts of ordinary Portland cement, 20 parts of lime, 2 parts of construction gypsum, and dry aluminum powder with fat 0.01 part, 12 parts of animal protein foaming agent THW-1, 1 part of epoxy resin powder, 0.1 part of carboxypropyl methyl cellulose ether, 0.1 part of silicone waterproof powder BS1042 (Wacker Company), mix well, and get on-site Acoustic material for fast construction.

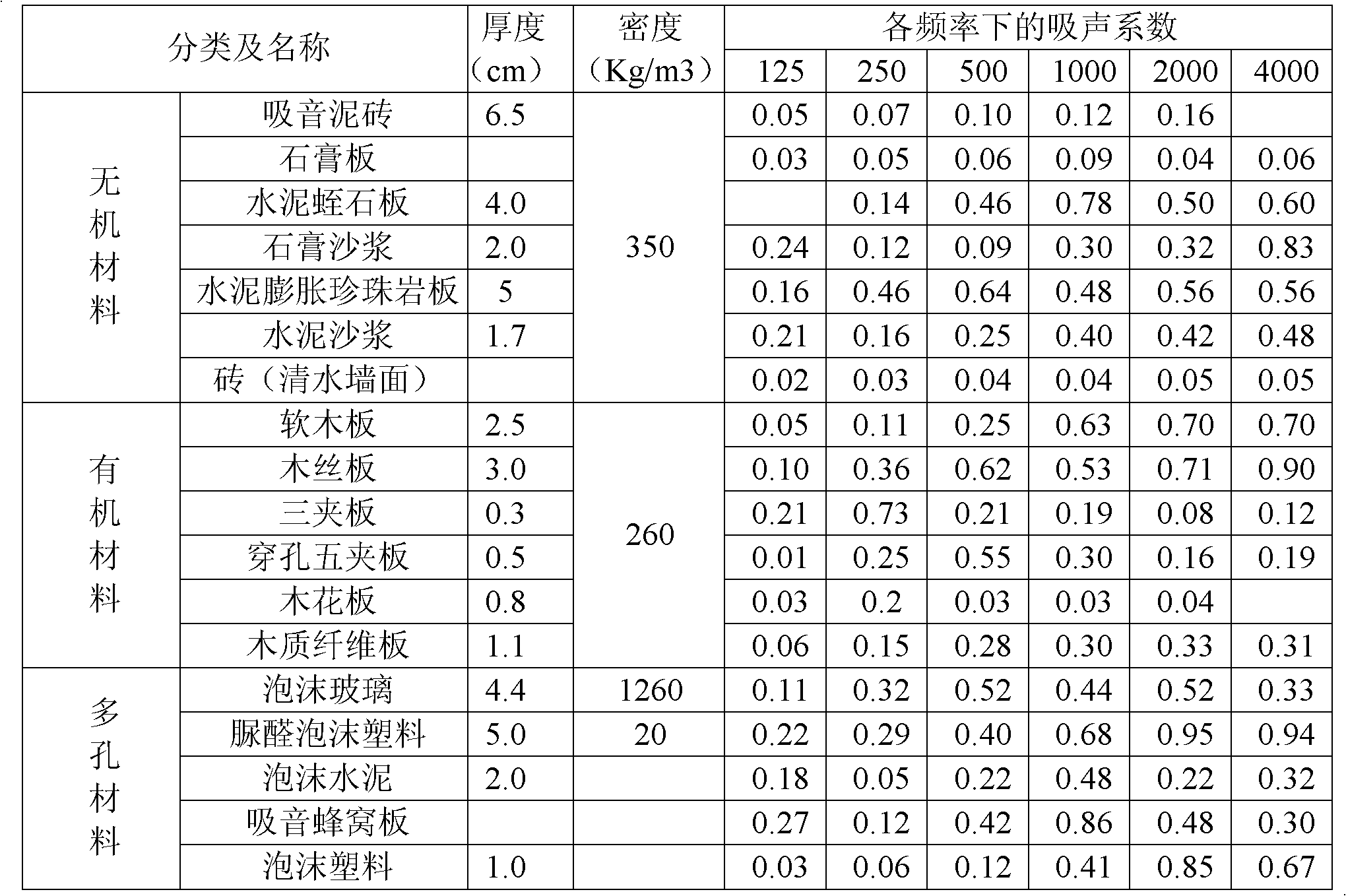

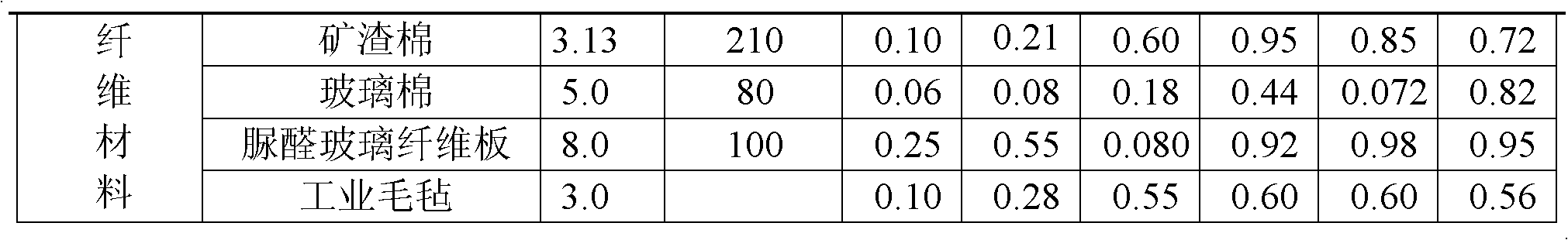

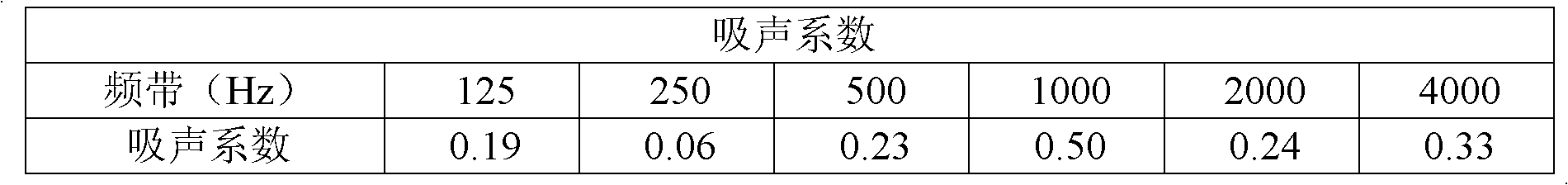

[0029] The method of use is: mix the sound-absorbing material with water at a ratio of 1:0.3, stir rapidly at a speed of 1000 rpm for 5 minutes, and then cast and spray. The sound absorption coefficient is 0.06~0.50, as shown in Table 2, compared with the sound absorption coefficient of the foam cement in the porous material in Table 1 in each frequency band, the sound absorption coefficient of the sound-absorbing material prepared...

Embodiment 2

[0033] According to the technical scheme of the present invention, a sound-absorbing material for rapid on-site construction has been prepared. Its components are 80 parts of ordinary Portland cement, 9.75 parts of lime, 5 parts of construction gypsum, and dry aluminum powder with fat 0.05 parts, 8 parts of plant protein foaming agent aGk, 1 part of epoxy resin powder, 0.1 part of carboxymethyl cellulose ether, 1 part of silicone waterproof powder (sold by MAXCELL SILICOAT), mix well, and get sound-absorbing materials for rapid construction on site Material.

[0034] The method of use is: mix the sound-absorbing material with water at a ratio of 1:0.3, stir rapidly at a speed of 800 rpm for 2 minutes, and then cast and spray. The sound absorption coefficient is 0.18~0.30.

Embodiment 3

[0036] According to the technical scheme of the present invention, a sound-absorbing material for rapid on-site construction has been prepared. Its components are 60 parts of ordinary Portland cement, 20 parts of lime, 2 parts of building gypsum, and dry aluminum powder with fat 0.05 part, 8 parts of sodium lauryl sulfate, 1 part of epoxy resin powder, 0.1 part of carboxymethyl cellulose ether, 0.1 part of organic silicon waterproof powder BS1042 (Wacker company), mix well, and obtain the rapid construction site sound-absorbing material.

[0037] The method of use is: mix the sound-absorbing material with water at a ratio of 1:0.5, stir rapidly at a speed of 900 rpm for 10 minutes, and then cast and spray. The sound absorption coefficient is 0.24~0.50.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap