Gas fractionation method

A technology of gas fractionation and condenser, applied in the direction of distillation purification/separation, organic chemistry, etc., can solve the problems of increased floor area and operating costs, waste, unusable heat sources, etc., to reduce equipment investment, design pressure reduction, cooling The effect of load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

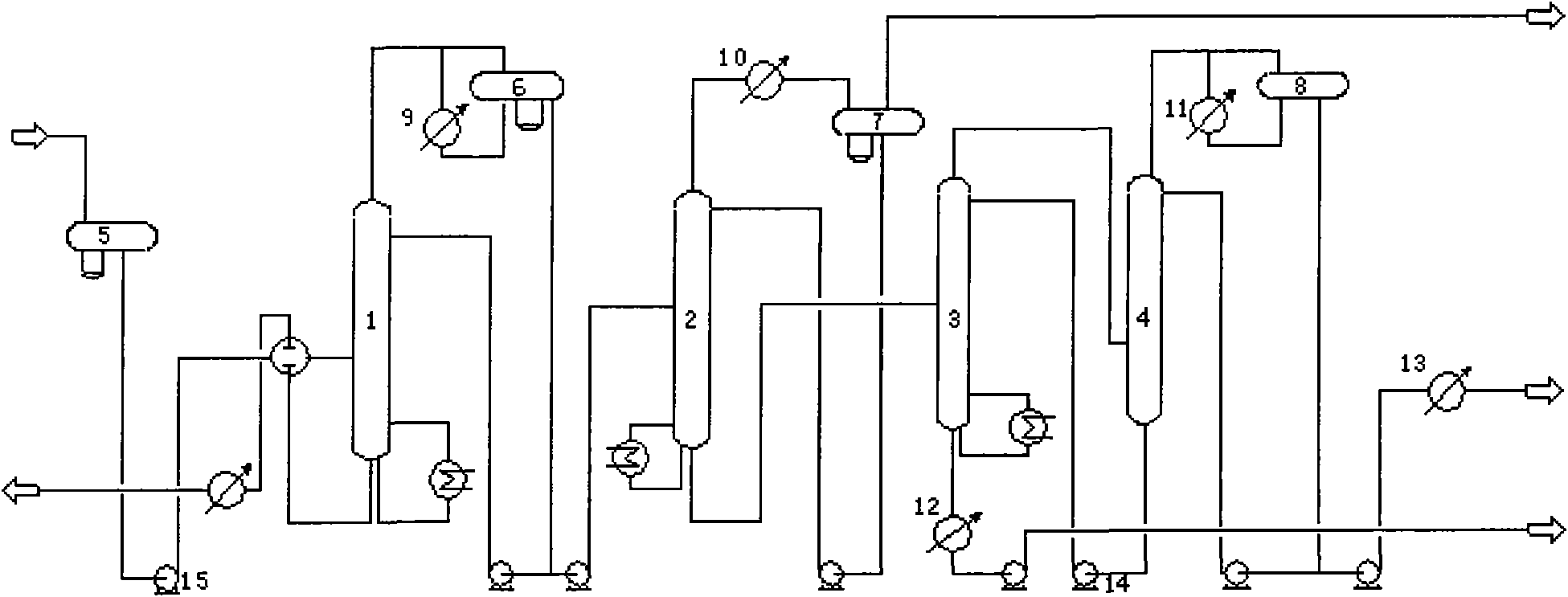

[0038] Such as figure 1 As shown, when the original device is transformed, it is only necessary to change the tubes of the depropanizer overhead condenser 9, deethanizer overhead condenser 10, and propylene overhead condenser 11 from circulating water to chilled water at 5-10°C , if the original top of the tower is condensed and cooled to an air cooler, the air cooler needs to be changed to a shell-and-tube or plate condenser. The pressure is 1.5-1.8MPa, the gauge pressure at the top of the second propylene tower 4 is 0.8-1.1MPa, the feed pump 15 of the device is modified or replaced, the head of the pump is 160 meters, the diameter of each tower remains unchanged, and the process flow is the same as that without modification The processing flow of the device can be increased by 50% without changing the internal components of the tower.

Embodiment 2

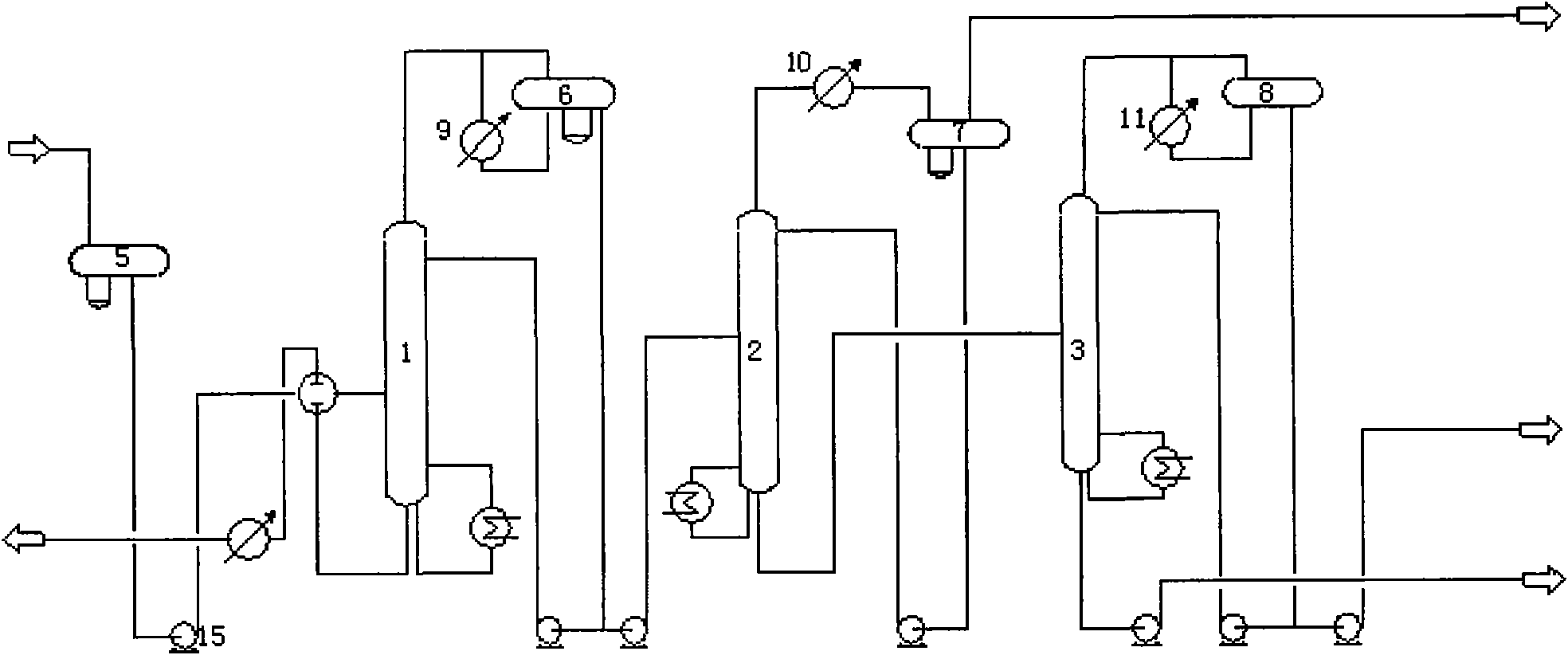

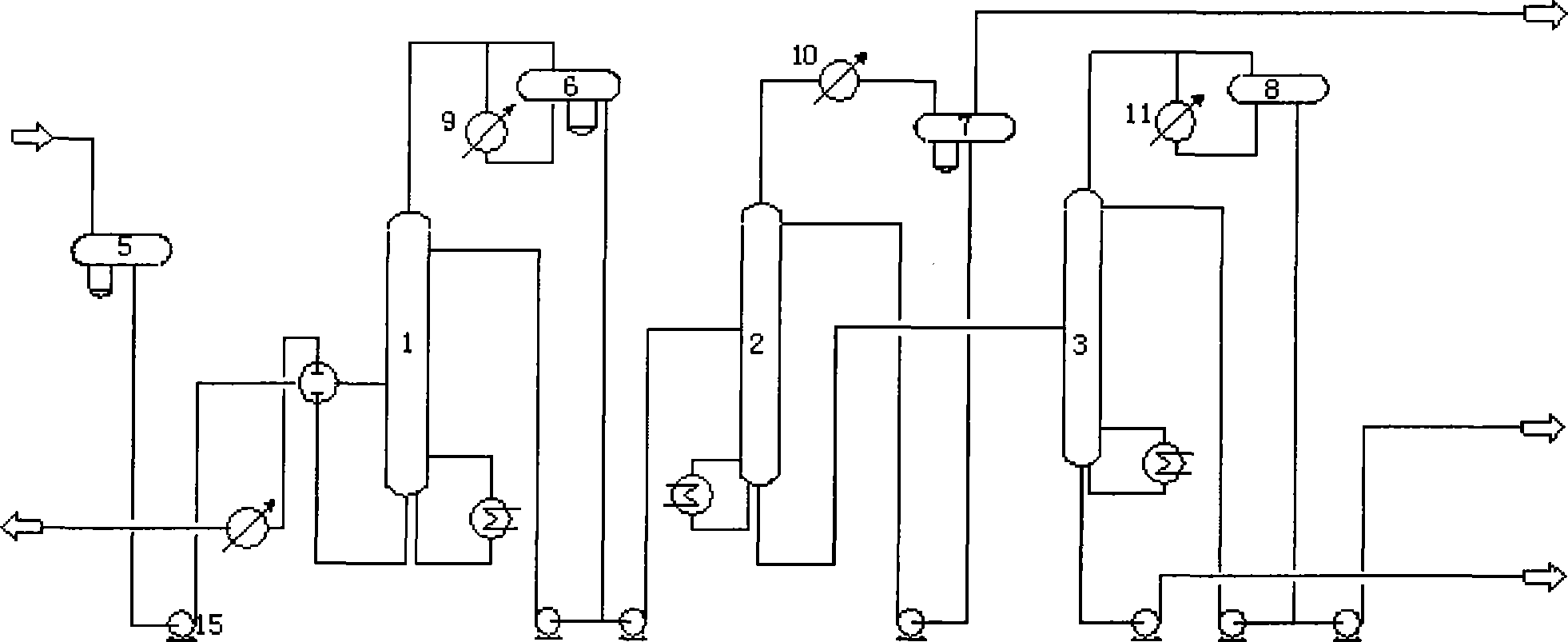

[0040] Such as figure 2 As shown, if the device is newly built and adopts the chilled water process, the number of propylene tower trays can be reduced from 200 to 130 layers, and only one propylene tower can be used, and the skirt of each tower is lowered by 2 meters. The design pressure is reduced.

[0041] as attached figure 2As shown, after the raw material liquefied gas after desulfurization passes through the raw material buffer tank 5, it is sent into the depropanizer 1 with the device feed pump 15, and the pressure at the top of the depropanizer 1 is controlled at 0.8 to 1.1 MPa. The C3 fraction enters the depropanizer top reflux tank 6 after being condensed by the depropanizer top condenser 9, a part of the liquid is used as the reflux of the depropanizer tower, and the other part is sent into the deethanizer tower 2 through the deethanizer feed pump, and the bottom of the tower is The C4 fraction is cooled by heat exchange and then exits the device; the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com