Synthesis method of high-purity p-tert-butylcatechol

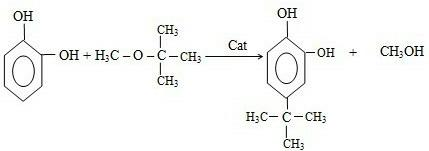

A technology of tert-butylcatechol and synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, chemical recovery, etc., to achieve the effects of low production cost, reduced loss of raw materials, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

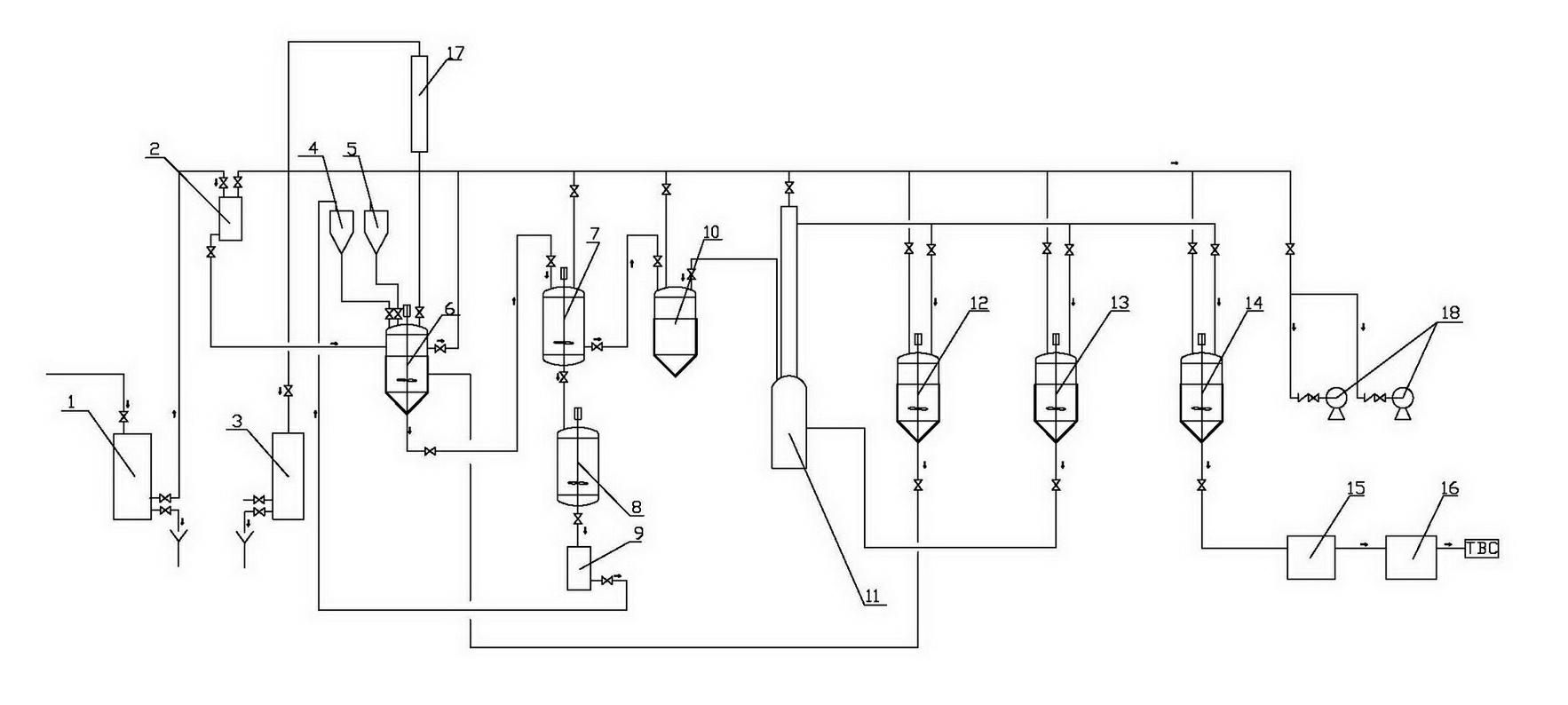

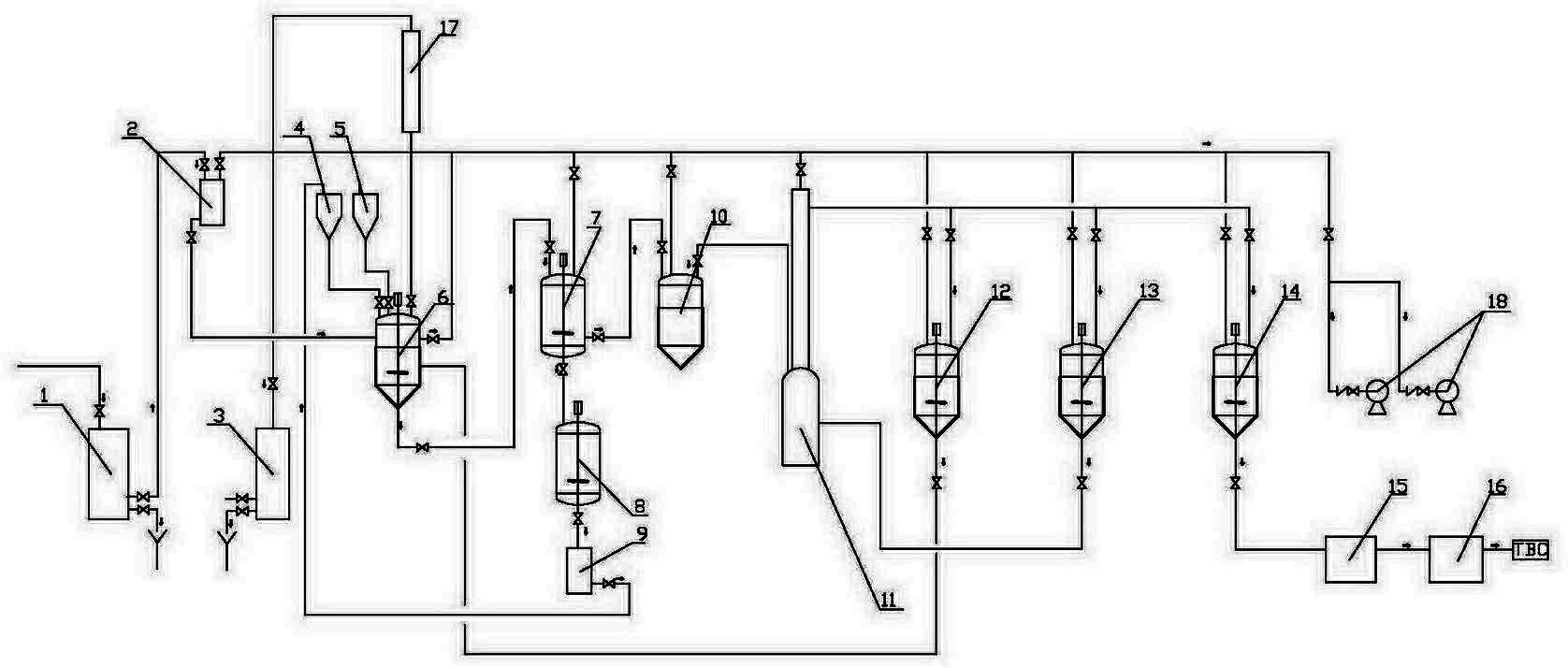

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: 200kg pyrocatechol is added in the synthetic kettle 6 through raw material warehouse 5, 40kg methyl tert-butyl ether is also added in the synthetic kettle 6 from storage tank 1, elevated tank 2 by negative pressure, simultaneously from catalyst material Add 10kg of NKC-99 catalyst to bin 4, heat the synthesis kettle 6 to 70-100°C, start stirring, raise the temperature to 100-110°C, control the reaction pressure to less than 0.04MPa, react for 3-5 hours, cool down to 85°C, and condense The reaction by-product methanol is flashed out by the device 17, and enters the methanol recovery tank 3. Heat the synthesis liquid in the synthesis kettle 6 to 130-160°C, control the reaction pressure to be less than 0.04MPa, stir for 2-4 hours, cool down to 100°C, send it to the filter 7 to filter out the NKC-99 catalyst, and the synthesis liquid enters a stable state. Kettle 10. After the filtered NKC-99 catalyst is regenerated by the regeneration kettle 8 and the regene...

Embodiment 2

[0017] Embodiment 2: 200kg catechol is added in the synthetic kettle 6 through raw material bin 5, will go out 60kg methyl tertiary butyl ethers also add in the synthetic kettle 6 from storage tank 1, head tank 2 by negative pressure, simultaneously from catalyst Add 15kg of NKC-99 catalyst to silo 4, heat the synthesis kettle 6 to 70-100°C, start stirring, raise the temperature to 100-110°C, control the reaction pressure to less than 0.04MPa, react for 3-5 hours, cool down to 85°C, and The condenser 17 flashes methanol as a by-product of the reaction, and enters the methanol recovery tank 3 . Heat the synthesis liquid in the synthesis kettle 6 to 130-160°C, control the reaction pressure to be less than 0.04MPa, stir for 2-4 hours, cool down to 100°C, send it to the filter 7 to filter out the NKC-99 catalyst, and the synthesis liquid enters a stable state. Kettle 10. After the filtered NKC-99 catalyst is regenerated by the regeneration kettle 8 and the regenerator 9, it is se...

Embodiment 3

[0018] Embodiment 3: 250kg pyrocatechol is added in the synthetic kettle 6 through raw material warehouse 5, 120kg methyl tert-butyl ether is also added in the synthetic kettle 6 from storage tank 1, elevated tank 2 by negative pressure, simultaneously from catalyst material Add 17kg of NKC-99 catalyst to bin 4, heat the synthesis kettle 6 to 70-100°C, start stirring, raise the temperature to 100-110°C, control the reaction pressure to less than 0.04MPa, react for 3-5 hours, cool down to 85°C, and condense The reaction by-product methanol is flashed out by the device 17, and enters the methanol recovery tank 3. Heat the synthesis liquid in the synthesis kettle 6 to 130-160°C, control the reaction pressure to be less than 0.04MPa, stir for 2-4 hours, cool down to 100°C, send it to the filter 7 to filter out the NKC-99 catalyst, and the synthesis liquid enters a stable state. Kettle 10. After the filtered NKC-99 catalyst is regenerated by the regeneration kettle 8 and the regen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com