Preparation method of biodegradable emulsion film material

A biodegradable and membrane material technology, applied in the field of preparation of biodegradable emulsion membrane materials, can solve the problems of unstable structure of emulsion membrane materials, poor water vapor barrier properties, weak mechanical strength, etc. Improved barrier properties and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The first step gelatin is prepared into a 5% (w / w) aqueous solution, and the pH is adjusted to 8.0 after fully hydrating, and 40% (w / w gelatin) glycerin and 20% (w / w gelatin) olive oil are added;

[0022] The second step is to pre-homogenize the material obtained in step 1 with a high-speed disperser at a speed of 6000rpm, homogenize for 5 minutes, and then use a micro-jet nano-homogenizer for second homogenization, the conditions are: 150MPa, 1 cycle;

[0023] The third step is to degas the film-forming liquid obtained in step 2 under a vacuum of 0.8MPa for 3 minutes, measure 45ml of film-forming liquid and pour it into a plexiglass box, and place it in a constant temperature and humidity box at 25°C and 40% RH to dry for 36 hours. Obtain emulsion film material;

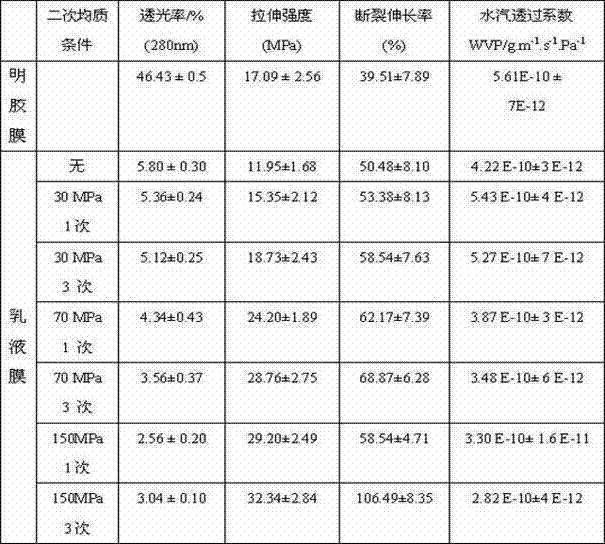

[0024] In this example, performance tests were also carried out on the emulsion membrane materials obtained under different homogenization conditions. The pre-homogenization time was 5 minutes and 3 minutes r...

Embodiment 2

[0029] The first step gelatin is prepared into a 5% (w / w) aqueous solution, and the pH is adjusted to 8.0 after fully hydrating, and 40% (w / w gelatin) glycerin and 20% (w / w gelatin) olive oil are added;

[0030] The second step is to pre-homogenize the material obtained in step 1 with a high-speed disperser at a speed of 20,000 rpm for 5 minutes, and then use a micro-jet nano-homogenizer for secondary homogenization under the following conditions: 150MPa, 1 cycle;

[0031] The third step is to degas the film-forming liquid obtained in step 2 under a vacuum of 0.8MPa for 3 minutes, measure 45ml of film-forming liquid and pour it into a plexiglass box, and place it in a constant temperature and humidity box at 25°C and 40% RH to dry for 36 hours. Obtain emulsion film material;

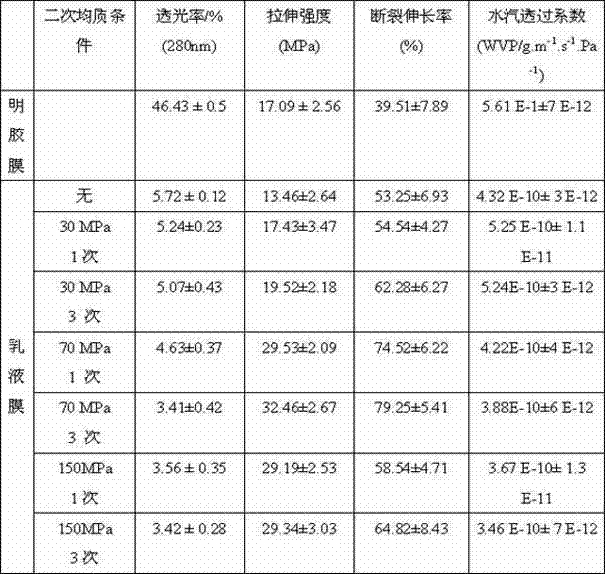

[0032] In this example, performance tests were also carried out on the emulsion membrane materials obtained under different homogenization conditions. The pre-homogenization time was 5 minutes and 3 minu...

Embodiment 3

[0037] The first step gelatin is prepared into a 5% aqueous solution, and the pH is adjusted to 8.0 after fully hydrating, adding 40% (w / w) glycerin and 5% (w / w gelatin) olive oil;

[0038]The second step is to pre-homogenize the material obtained in step 1 with a high-speed disperser at a speed of 6000rpm, homogenize for 3min, and then homogenize for the second time with micro-jet flow at a condition of 70 MPa for 3 cycles;

[0039] The third step is to degas the material obtained in step 2 for 3 minutes under a vacuum of 0.8 MPa, measure 45 mL of volume, pour it into a plexiglass box, and place it in a constant temperature and humidity box at 25 ° C and 40% RH to dry for 36 hours to obtain an emulsion Membrane material;

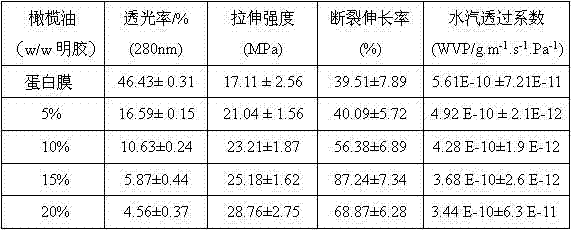

[0040] In this example, performance tests were performed on emulsion film materials obtained from oil phases with different proportions. The content of olive oil was 5%, 10%, 15%, and 20%, respectively, and other conditions remained unchanged. The results a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com