Pigment dispersing agent composite containing phosphate ester structure and preparation method thereof

A pigment dispersant and phosphate-containing technology, which is applied in the direction of phosphorus organic compounds and pigment pastes, can solve the problems of difficult dispersion, decreased tinting power, long grinding time, etc., and achieve low viscosity, high stability, and high tinting power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

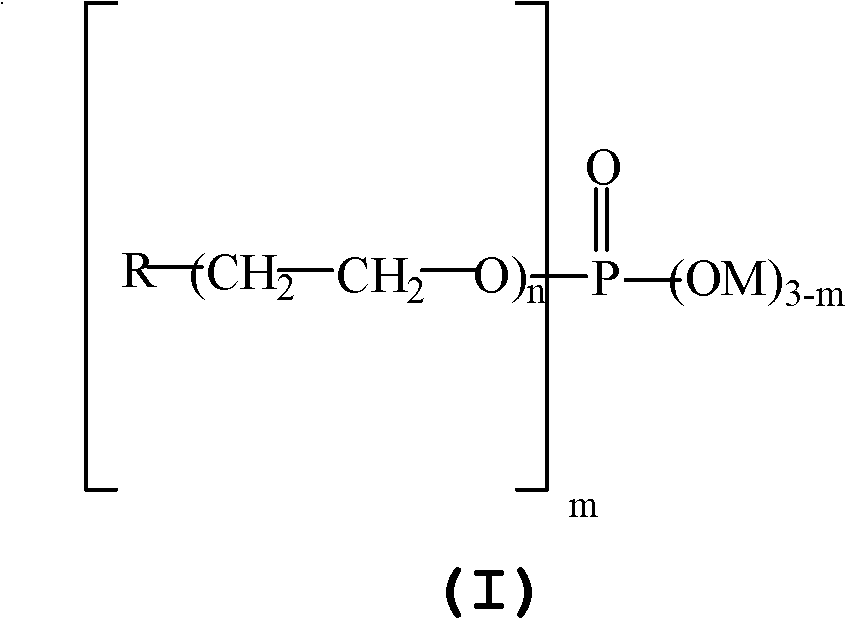

Method used

Image

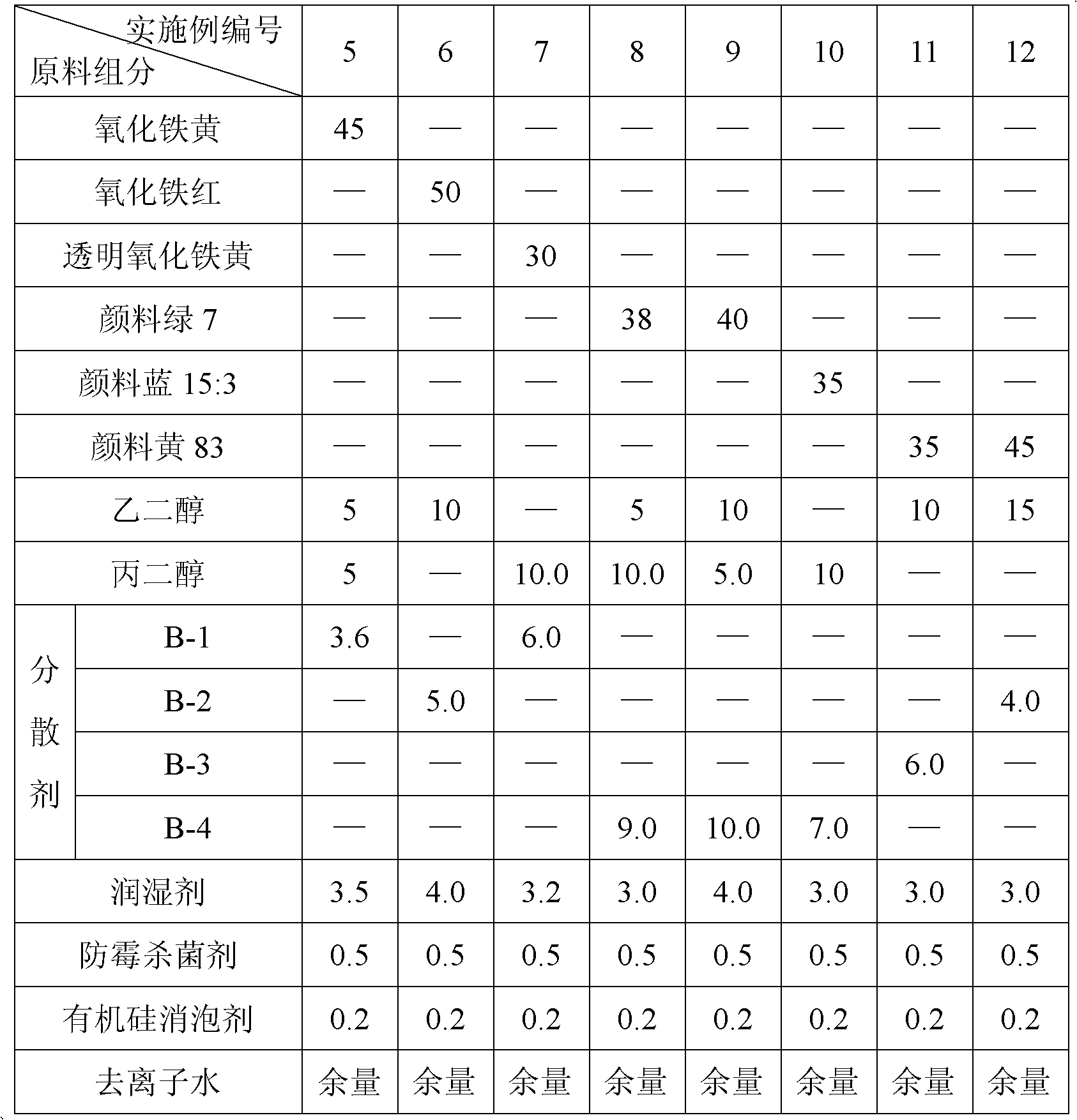

Examples

Embodiment 1

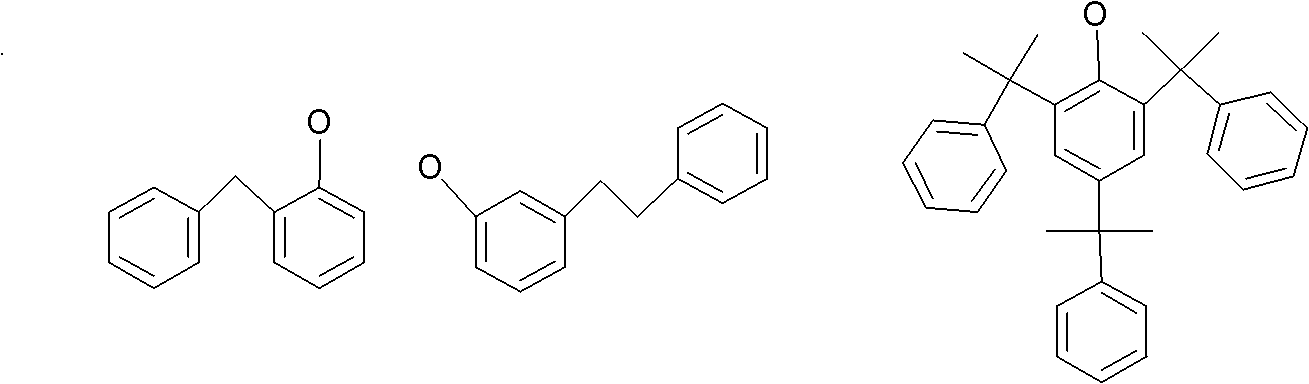

[0028] 0.2 moles of 2-benzylphenol, 3 moles of oxirane and 0.5 gram of potassium hydroxide in the autoclave, after reacting for 1 hour under the conditions of 80°C and 0.8MPa, the product obtained was under nitrogen protection, and 0.06 moles of phosphorus pentoxide were reacted for 2 hours at 30°C to 45°C to obtain dispersant A-1;

[0029] 0.4 moles of 2,4,6-tris(1-toluene-1-phenylethyl)phenol, 2.4 moles of ethylene oxide and 0.3 grams of sodium hydroxide were reacted in an autoclave at 60°C and 0.2MPa After 1 hour, the obtained product was reacted with 0.2 mole of phosphorus pentoxide under the condition of 50°C to 65°C for 2 hours under the protection of nitrogen to obtain dispersant A-2;

[0030] 0.2 moles of 3-phenethylphenol, 6 moles of ethylene oxide and 0.8 grams of sodium hydroxide were reacted for 1 hour at 120° C. and 1.0 MPa in an autoclave, and the resulting product was under nitrogen protection. React with 0.05 mole of phosphorus pentoxide for 1 hour under the c...

Embodiment 2

[0033] 0.2 moles of 3-phenethylphenol, 2 moles of ethylene oxide and 0.5 grams of potassium hydroxide were reacted for 1 hour at 80° C. and 0.5 MPa in an autoclave, and the resulting product was protected under nitrogen. React with 0.06 moles of phosphorus pentoxide at 50°C to 65°C for 2 hours to obtain dispersant A-4;

[0034] 0.5 moles of 2,4,6-tris(1-toluene-1-phenylethyl)phenol, 10 moles of ethylene oxide and 1.2 grams of sodium hydroxide in an autoclave under the conditions of 60°C and 0.4MPa After reacting for 1 hour, the obtained product was reacted with 0.2 mole of phosphorus pentoxide under the condition of 40° C. to 55° C. for 1.5 hours under the protection of nitrogen to obtain dispersant A-5.

[0035] After mixing the above-mentioned dispersants A-4 and A-5 uniformly at a mass ratio of 1:2, adjust the pH value to 9.0 with 30wt.% potassium hydroxide aqueous solution to obtain a pigment dispersant composition B-2 containing a phosphate ester structure .

Embodiment 3

[0037] Prepare dispersant A-3 and A-4 according to the method described in embodiment 1 and 2 respectively, and after A-3 and A-4 are mixed with the mass ratio of 3: 1, adjust pH with 30wt.% potassium hydroxide aqueous solution The value was 9.5, and the pigment dispersant composition B-3 containing a phosphate ester structure was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com