Hyperbranched ultraviolet cured coating and preparation method thereof

A technology of curing coatings and ultraviolet light, which is applied in the field of coatings, can solve the problems of physical and chemical performance indicators such as paint film adhesion, pungent odor, high toxicity, and slow curing rate, etc., and achieve fast curing paint film physical and chemical properties and good compatibility. , the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

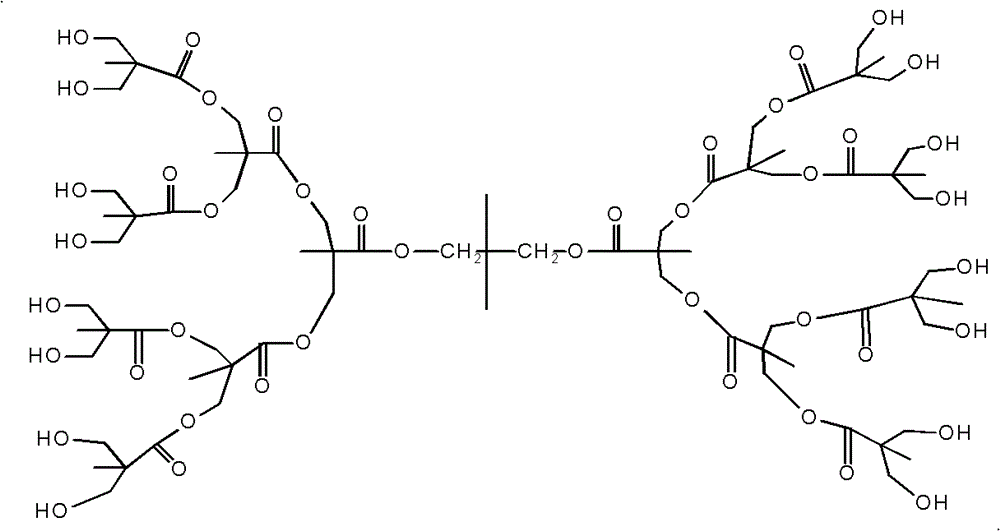

Image

Examples

Embodiment 1

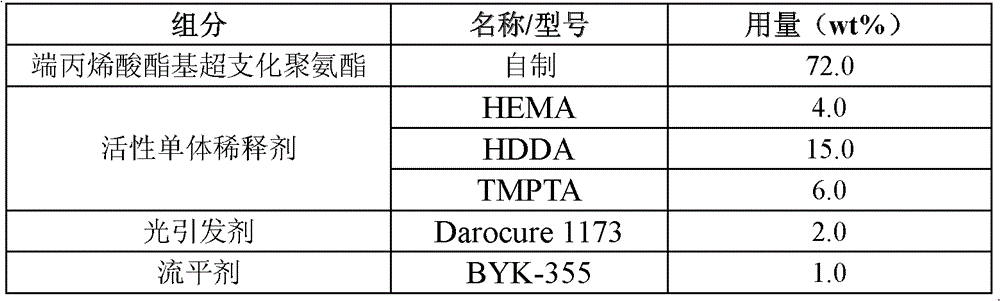

[0027] 1. For the hyperbranched UV-curable coating of this embodiment, its raw material composition is as shown in Table 1 by weight percentage:

[0028] Table 1 The formula composition of embodiment one hyperbranched UV-curable coating

[0029]

[0030] 2. The preparation method of the hyperbranched UV-curable coating of the present embodiment is as follows:

[0031] (1) Synthesis of terminal acrylate hyperbranched polyurethane

[0032] (1-1) Preparation of hyperbranched polyester (HBPE)

[0033] Add neopentyl glycol, dimethylolpropionic acid and p-toluenesulfonic acid into the reaction flask, according to the molar ratio of neopentyl glycol: dimethylolpropionic acid=1:14, the amount of p-toluenesulfonic acid is by weight percentage It is 0.05% of the total amount of neopentyl glycol and dimethylolpropionic acid; after reacting at 140°C for 4 hours under the protection of nitrogen, stop the nitrogen flow, change the pressure and vacuum to continue the reaction for 4 hour...

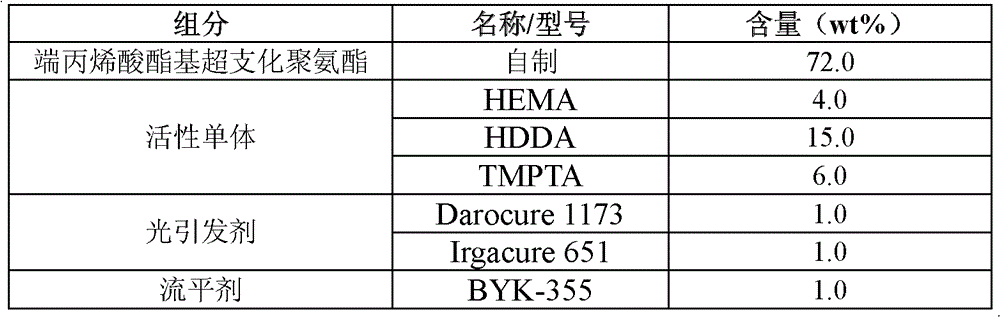

Embodiment 2

[0042] The difference between the present embodiment and the first embodiment is that in the preparation method of the hyperbranched UV-curable coating, the preparation of the semi-blocked isocyanate MDI HPA monomer in the step (1-2) is as follows:

[0043] Add diphenylmethane diisocyanate MDI and p-hydroxyanisole (the amount of which is 0.08% of the mass of MDI) into the reaction flask, use DBTDL as a catalyst, and dropwise add a mixed solution formed by dissolving hydroxypropyl acrylate in acetone under stirring , where the molar weight of hydroxypropyl acrylate is equal to that of diphenylmethane diisocyanate MDI, react at a temperature of 55°C for 3h to obtain a half-blocked isocyanate MDI·HPA monomer.

Embodiment 3

[0045] The difference between this embodiment and the first embodiment is that in the formula composition of the hyperbranched UV-curable coating, the reactive monomer diluent is only monofunctional HEMA (hydroxypropyl methacrylate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com