Anti-flow cementing slurry for well cementation

A cementing slurry and anti-channeling technology, which is applied in the drilling composition, chemical instruments and methods, etc., can solve the problem that the temperature, shearing and aging time of the latex anti-channeling cement slurry have great influence, and the compatibility of additives High requirements, difficult to control the gas generation time, etc., to achieve the effect of improving the resistance to fluid intrusion, wide application density and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the present invention provides a kind of low-density colloidal type anti-gas channeling cement slurry, the weight percentage of each component is based on 100% G grade cement, and the percentage of various additives accounting for G grade cement weight is: 50% lightening agent, 25% high-temperature strength stabilizer, 17% anti-channeling agent for acrylic modified ketone-aldehyde resin prepared by the present invention, 1.35% salt-resistant retarder, 0.2% defoamer, 70% tap water. The high-temperature strength stabilizer is microsilicon or amorphous silica with a purity greater than 95%, the salt-resistant retarder is acrylamide polymer, and the defoamer is polyether.

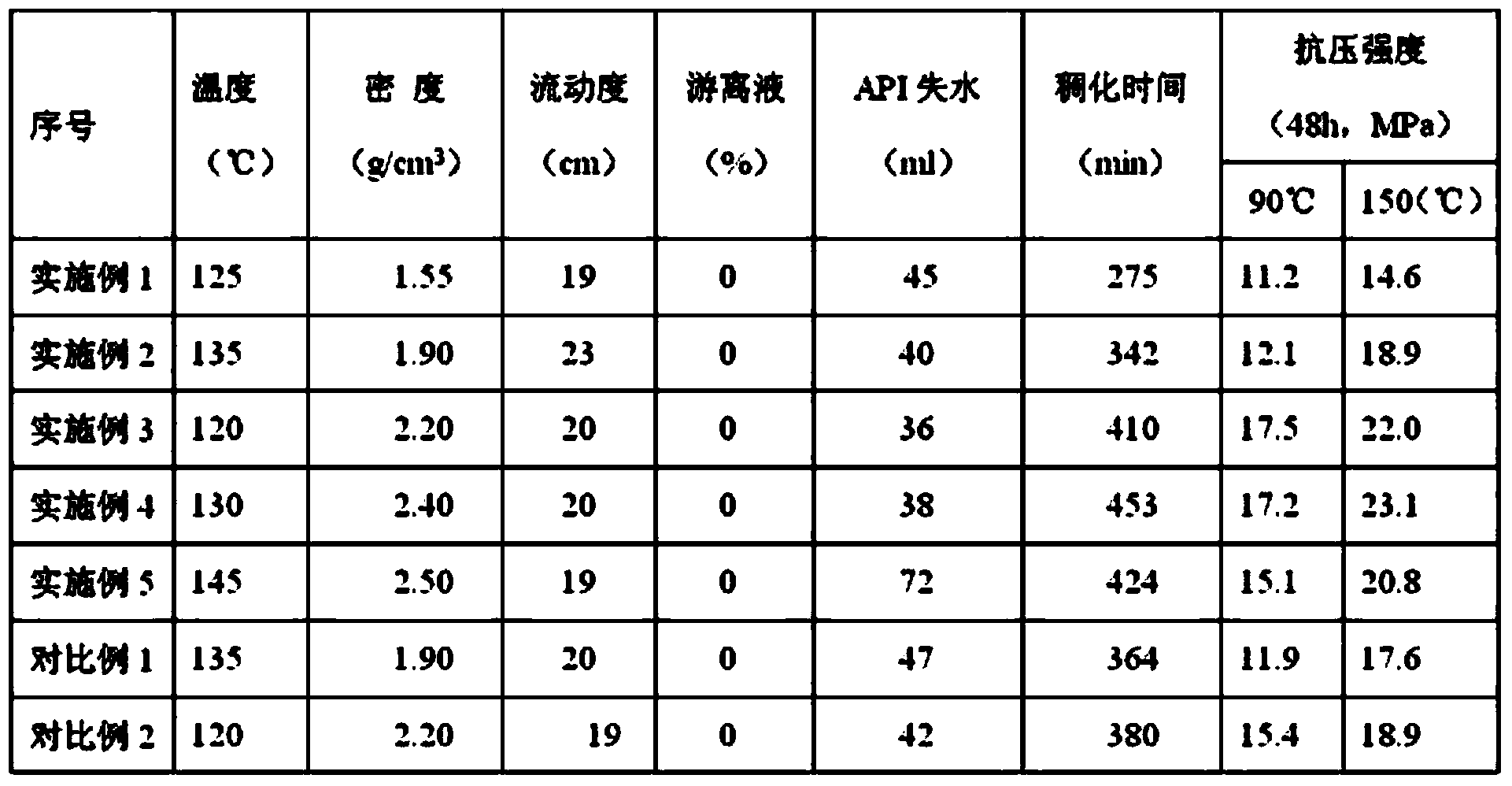

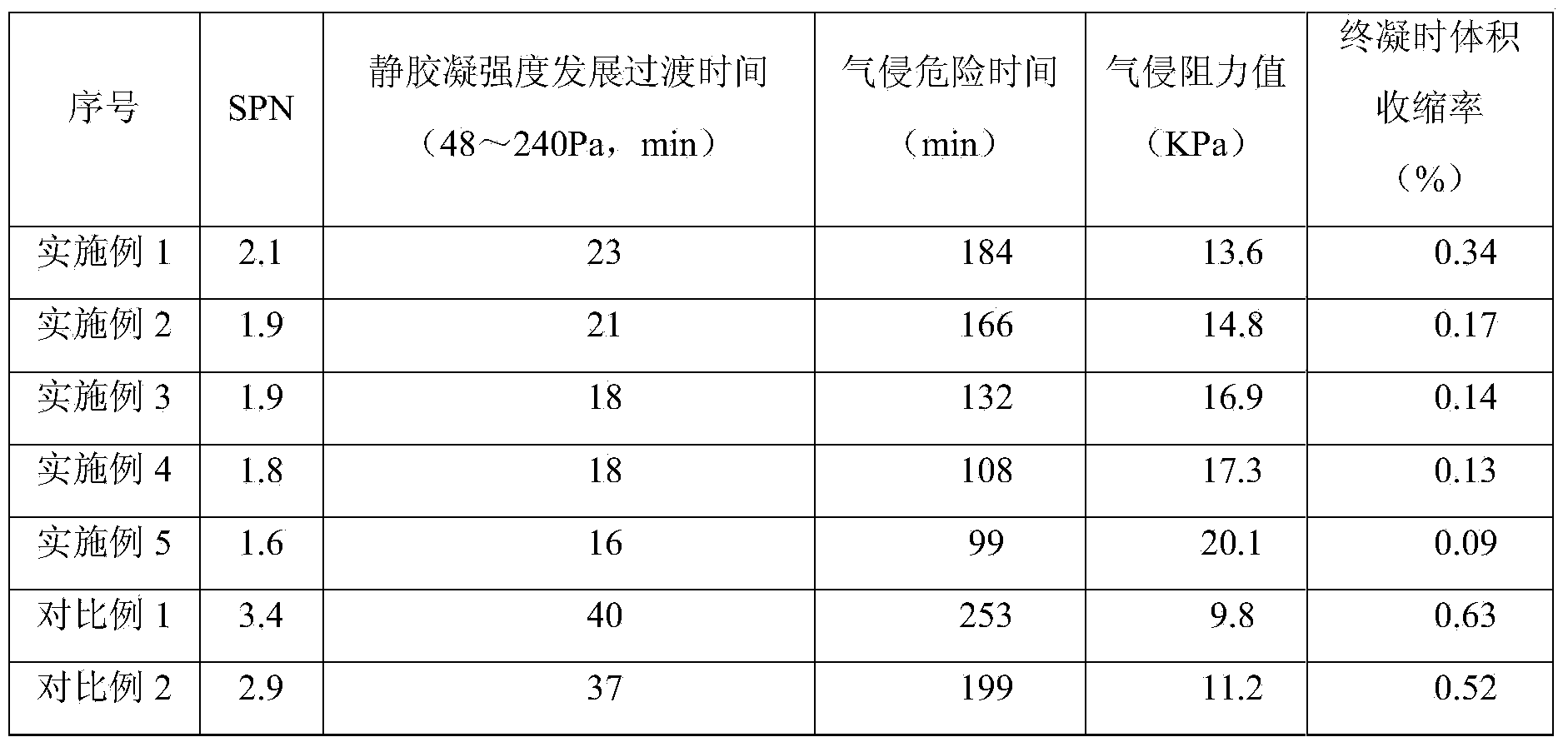

[0033] The raw materials were mixed and stirred together to prepare well cementing cement slurry, and the relevant properties of the cement slurry were measured, as shown in Table 1 and Table 2.

Embodiment 2

[0034] Embodiment 2: the present invention provides a kind of conventional density micelle type anti-gas channeling cementing cement slurry, the percentage by weight of each component is based on 100% G grade cement, and the percentage of various additives accounting for G grade cement weight is: 30% high-temperature strength stabilizer, 8% modified ketone-formaldehyde resin anti-channeling agent prepared by the present invention, 1.2% salt-resistant retarder, 0.2% defoamer, 44% tap water. The high-temperature strength stabilizer is microsilicon or amorphous silica with a purity greater than 95%, the salt-resistant retarder is acrylamide polymer, and the defoamer is polyether. The raw materials were mixed and stirred together to prepare well cementing cement slurry, and the relevant properties of the cement slurry were measured, as shown in Table 1 and Table 2.

Embodiment 3

[0035] Embodiment 3: the present invention provides a kind of high density (2.20g / cm 3 ) Colloidal type anti-gas channeling cement slurry, the weight percentage of each component is based on 100% G-grade cement, and the percentage of various additives in the weight of G-grade cement is: 95% weighting agent, 30% high temperature stable strength agent, 4.5% modified ketone-formaldehyde resin anti-channeling agent prepared by the present invention, 1.5% anti-salt retarder, 0.15% defoamer, 36% tap water. The high-temperature strength stabilizer is microsilicon or amorphous silica with a purity greater than 95%, the salt-resistant retarder is acrylamide polymer, and the defoamer is polyether. The raw materials were mixed and stirred together to prepare well cementing cement slurry, and the relevant properties of the cement slurry were measured, as shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com