Sample treatment method for measuring antimony in polyester chip with flame atomic absorption spectrometry

A flame atomic absorption, polyester slicing technology, applied in the preparation of test samples, color/spectral property measurement, etc. The effect of low limit, low cost of use and less spectral line interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the sample treatment method of antimony in polyester chips determined by flame atomic absorption spectrometry may further comprise the steps:

[0017] (1) Weigh 1.000g of polyester chips into a 50ml quartz beaker, place the beaker on an electric heating plate for low-temperature heating.

[0018] (2) When the sample in the quartz beaker is completely carbonized, put it into a muffle furnace and set the temperature of the furnace body at 300° C., and ash it for 1 hour.

[0019] (3) Then take out the quartz beaker and cool to room temperature, add 2ml of 10% magnesium nitrate in the beaker and evaporate to dryness on the electric heating plate.

[0020] (4) Put the quartz beaker into a muffle furnace, set the temperature of the furnace body to 500° C., and incinerate for 2 hours. The completely ashed samples were taken out and cooled at room temperature.

[0021] (5) Add 2ml of concentrated hydrochloric acid to the beaker, dissolve the sample and transfer ...

Embodiment 2

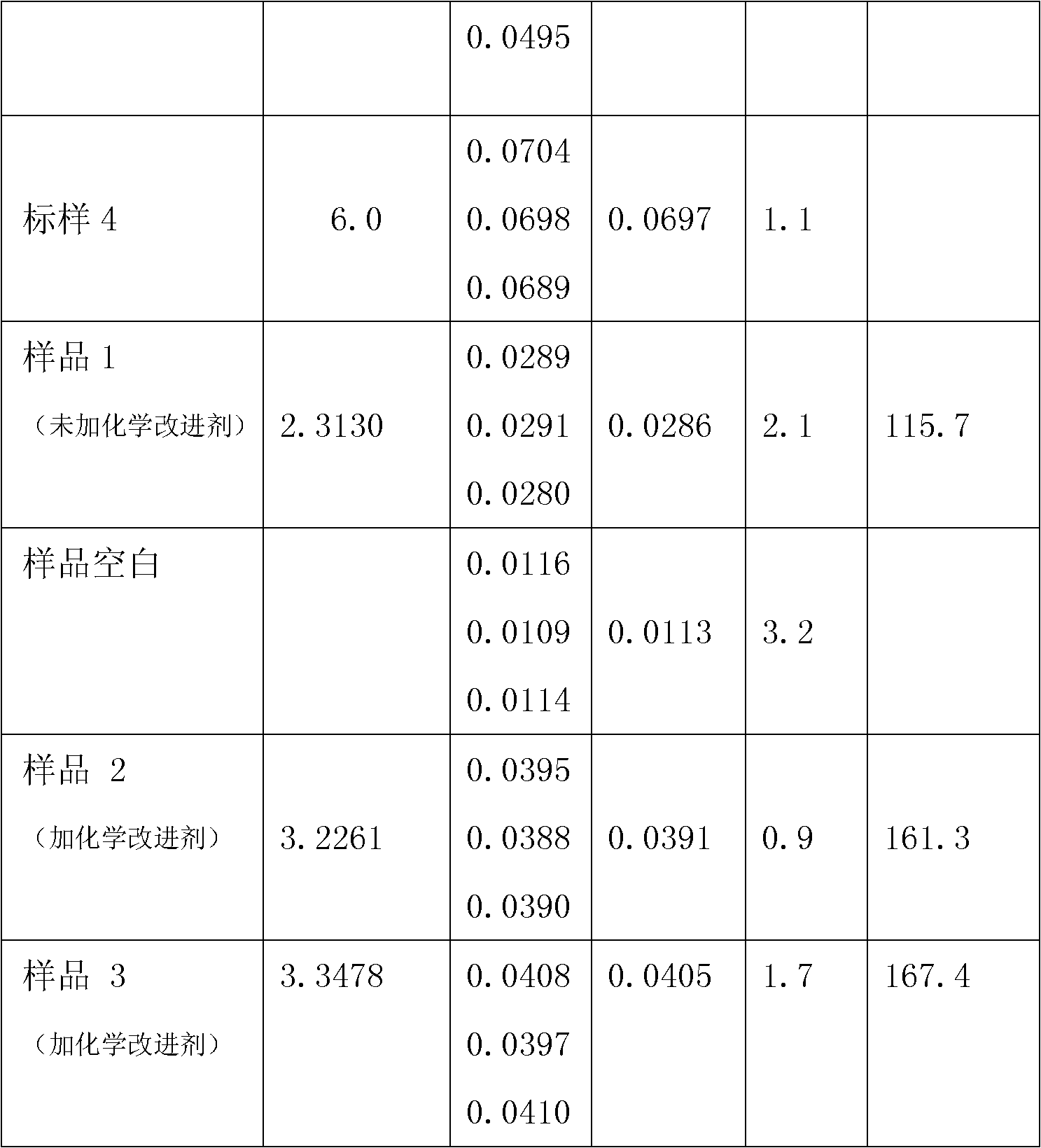

[0023] Embodiment 2: concrete experimental test of the present invention:

[0024] 1.1 Instruments and equipment

[0025] WYS2200 atomic absorption spectrometer (Anhui Wanyi Technology), adjustable electric heating plate, WY802-II ultrapure water machine (Anhui Wanyi Technology), antimony hollow cathode lamp (Beijing Nonferrous Metals General Institute), muffle furnace (SX2-2.5 -12)

[0026] 1.2 Reagents and solutions

[0027] (1) Hydrochloric acid, super pure, 68-70%, product of Beijing Chemical Factory; (2) Magnesium nitrate, super pure, Sinopharm reagent; (3) High-purity deionized water. Resistivity ≥ 18MΩ.cm; (4) Antimony standard solution: 1000μg / mL, Beijing General Institute of Nonferrous Metals;

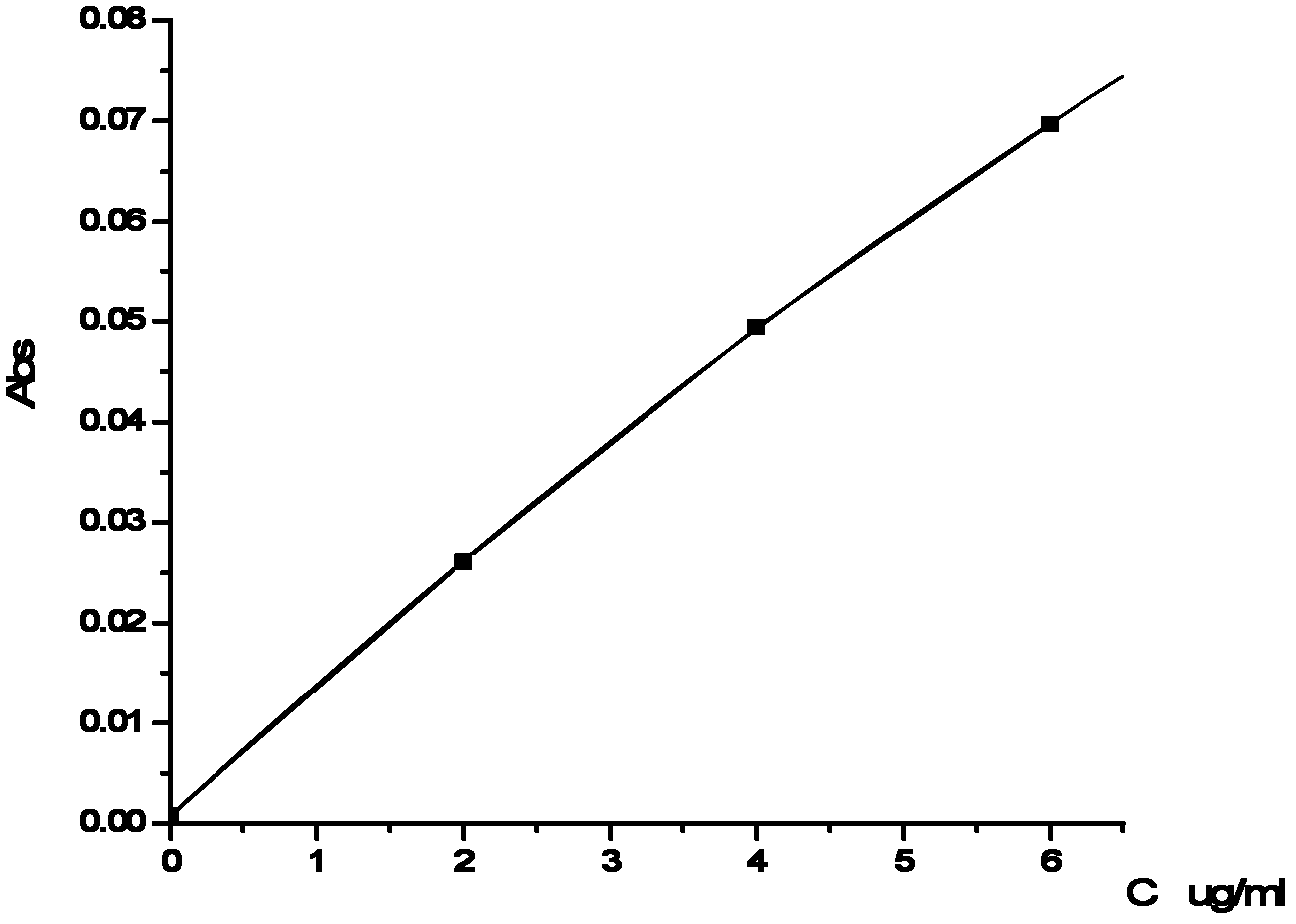

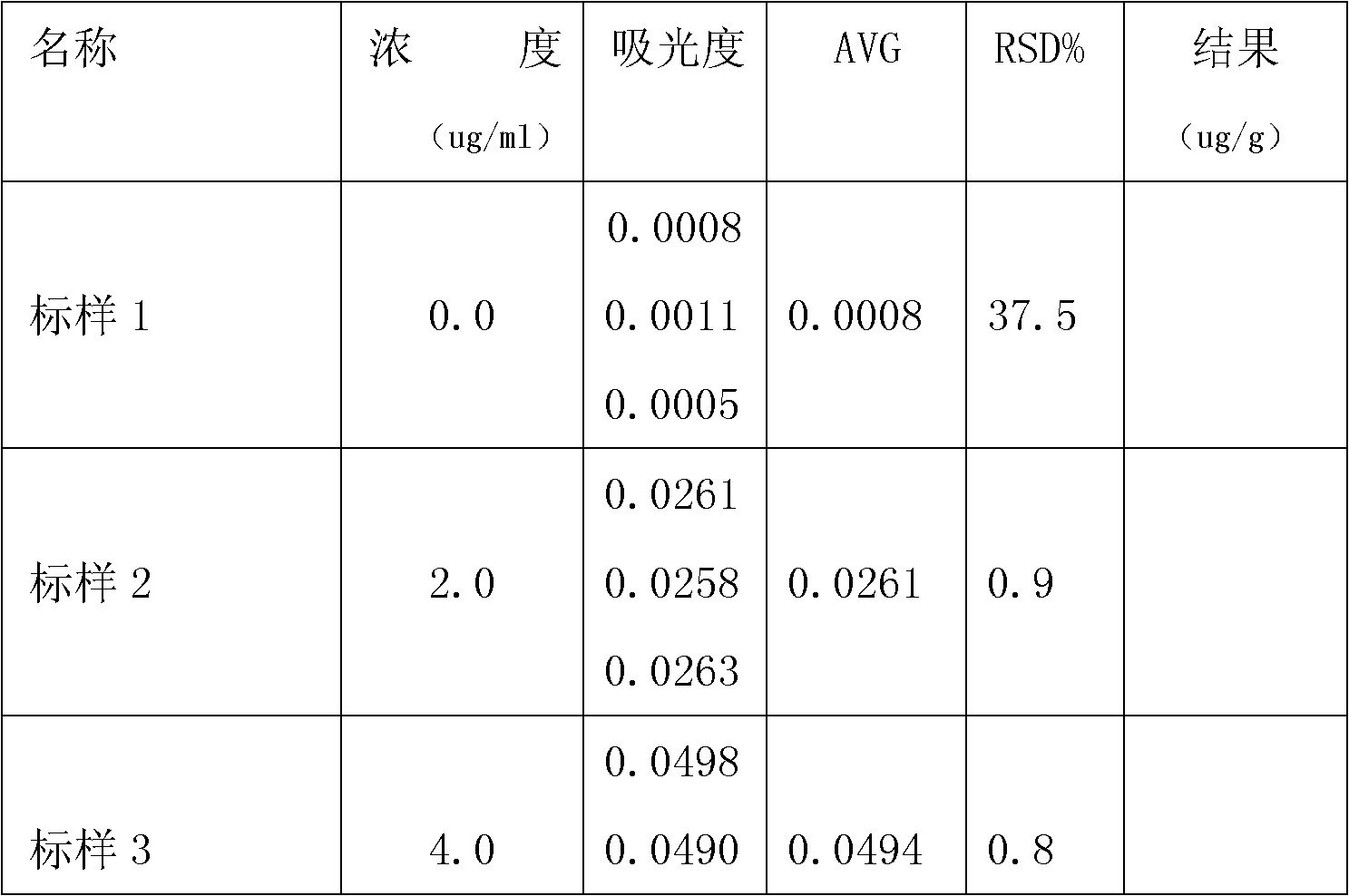

[0028] 1.3 Standard solution preparation

[0029] (1) Chemical improver: Magnesium nitrate solution Method: Take 10 grams of superior pure magnesium nitrate and add it to a beaker, add 50ml of deionized water to dissolve it, transfer it to a 100ml volumetric flask, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com