Method for detecting flaw of angle steel member by using ultrasonic guided waves

A technology of ultrasonic guided wave and angle steel parts, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of low efficiency and achieve the effect of high detection efficiency and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

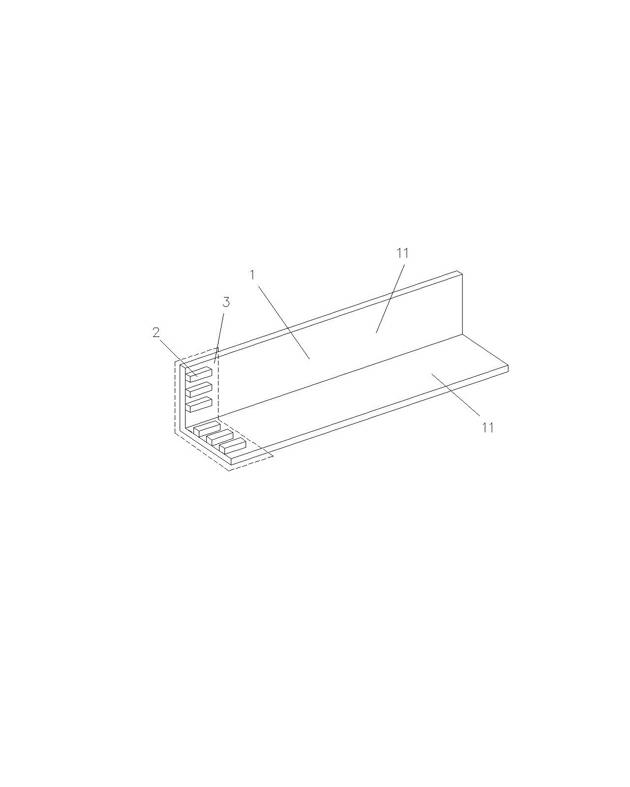

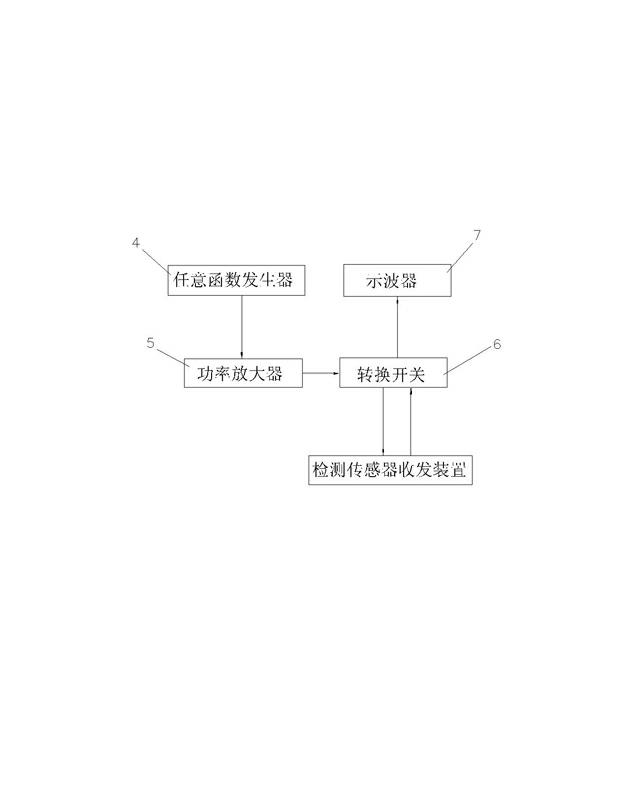

[0027] Such as figure 1 , image 3 and Figure 4 As shown, this embodiment uses 5# angle steel (50mm×50mm×3mm) as the detection object, including the following steps:

[0028] 1) According to the thickness of 5# angle steel side plate (3mm), width (50mm), length 1m, material density 7.85g / cm 3 , modulus of elasticity 2.06×10 11 N / m 3 , Poisson's ratio 0.3, longitudinal wave velocity 5960m / s and shear wave velocity 3260m / s establish the finite element model of angle steel piece 1.

[0029] 2) Simulate the propagation process of the ultrasonic guided wave excited by the sensor on the finite element model of the angle steel piece 1, obtain the group velocity of the ultrasonic guided wave propagation of a specific mode at a specific frequency, and establish a database of excitation frequency and modal wave velocity. When the excitation frequency is 70KHZ, the propagation speed of its waveform is 5120m / s.

[0030] 3) Taking the excitation conditions simulated by the fini...

Embodiment 2

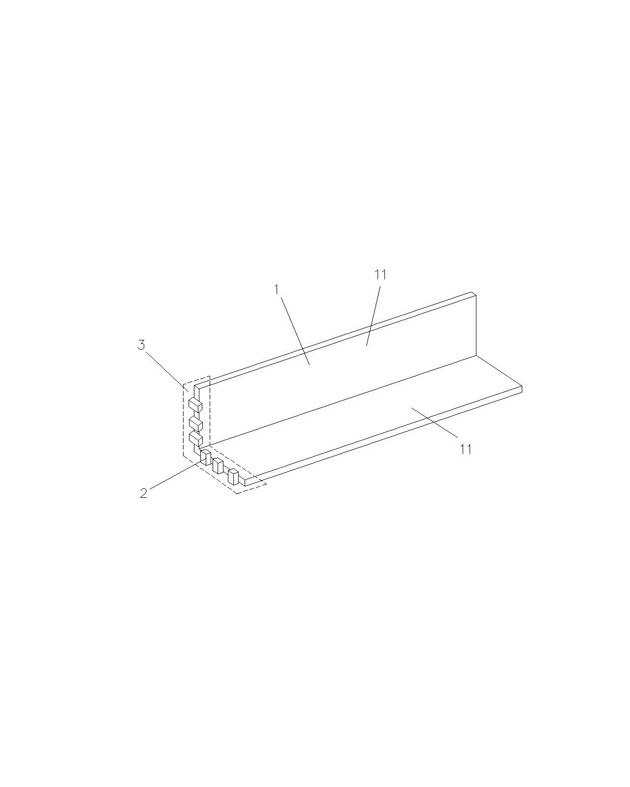

[0035] Such as figure 2 As shown, the 6 detection sensors 2 of this embodiment are evenly arranged in groups of 3 on the end faces of the "L"-shaped two side plates of the angle steel piece through special fixtures. The piezoelectric sensor used in this embodiment is a straight probe type, and the remaining steps Same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com