Manufacturing method of carrier for electrostatic image developer

An electrostatic image development and manufacturing method technology, which is applied in the directions of developer, electrography, optics, etc., can solve the problems of carrier durability not reaching the ideal goal, coating layer resin falling off, and difficulty in obtaining the coating layer, etc. Achieve the effects of easy market application, low production cost, and suppression of resistance and charge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

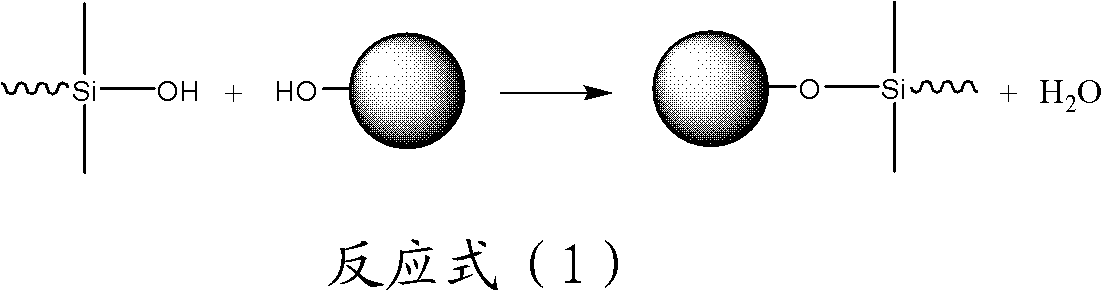

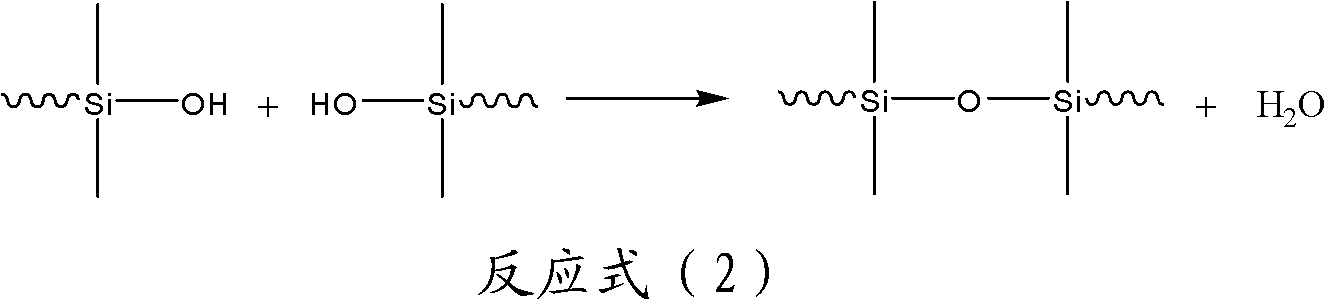

Method used

Image

Examples

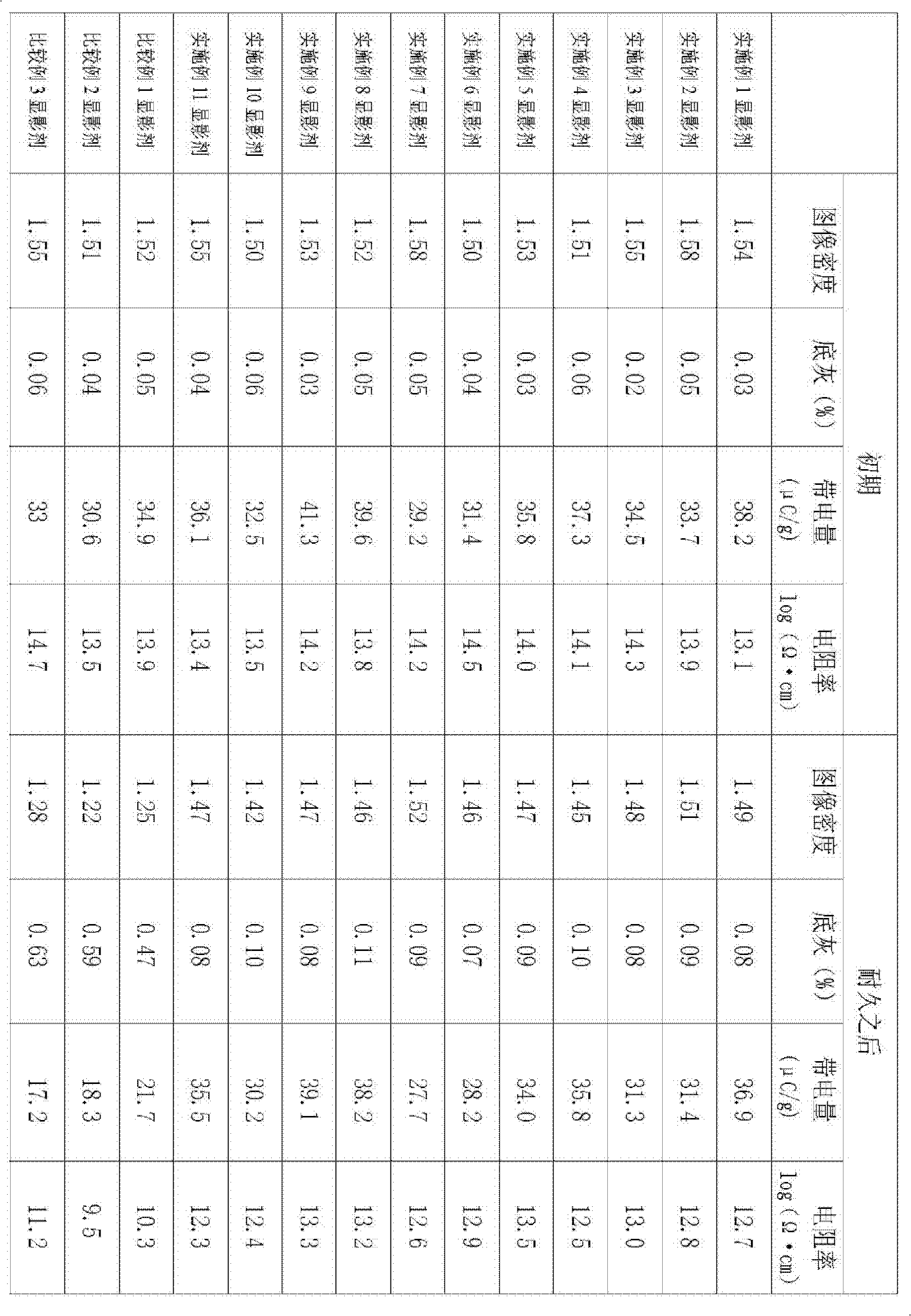

Embodiment 1

[0034]

[0035] 745g Fe 2 o 3 , 218 g Mn 3 o 4 , 24g MgO, 13g SrO are used as the raw material of the carrier core material, dispersed in 820g water, and ground with a ball mill to obtain a mixed slurry of the above substances, in addition, 10g polyacrylic acid is added as a dispersant, and 30g PVA-1788 solution is added as a binding agent agent. The slurry is sprayed into hot air at 250° C. with an airflow or centrifugal spray dryer to obtain dry particles with a particle size of 10-200 μm. The particles were put into an electric furnace and calcined at 800° C. for 2 hours, and the calcined powder was ground again by a ball mill into a slurry of small particles with an average particle diameter of 1 μm. Add the binder PVA, the dispersant polyacrylic acid (the addition amount is the same as above) and spray granulate again with a spray dryer to obtain dry particles with a particle size of 10-200um, and carry out sieving and classification to remove coarse and fine partic...

Embodiment 2

[0042] Except changing the silicone resin of 2 parts by mass into a mixture of 1 part by mass of silicone resin and 1 part by mass of styrene-methyl methacrylate resin, other conditions are basically the same as in Example 1, and the volume average particle diameter obtained is 37.1 μm The carrier particle 2 of Example 2.

Embodiment 3

[0044] Except changing the silicone resin of 2 mass parts into a mixture of 0.4 mass parts of silicone resin and 1.6 mass parts of styrene-methyl methacrylate resin, other conditions are basically the same as in Example 1, and the volume average particle diameter obtained is 37.4 μm Carrier Particle 3 of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com