Manufacturing method of carrier for electrostatic image developer

A technology for developing and manufacturing electrostatic images, which is applied in the directions of developer, electro-recording, optics, etc., and can solve the problems of unsatisfactory carrier durability, unsatisfactory results, and shedding of coating resin. Ease of market application, suppression of resistance and charge reduction, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

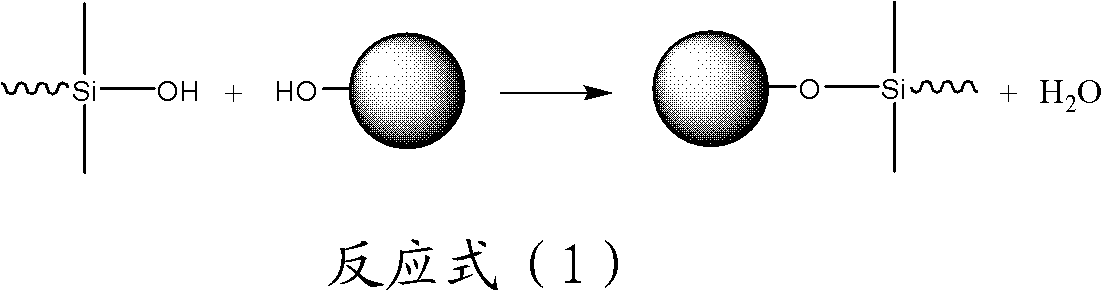

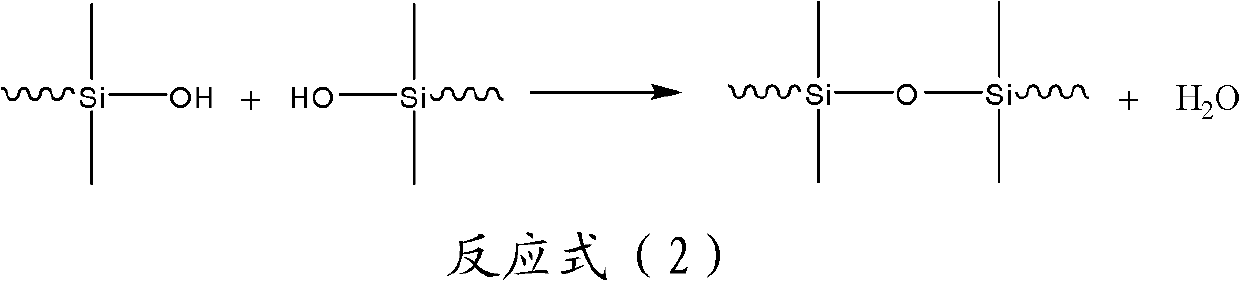

Method used

Image

Examples

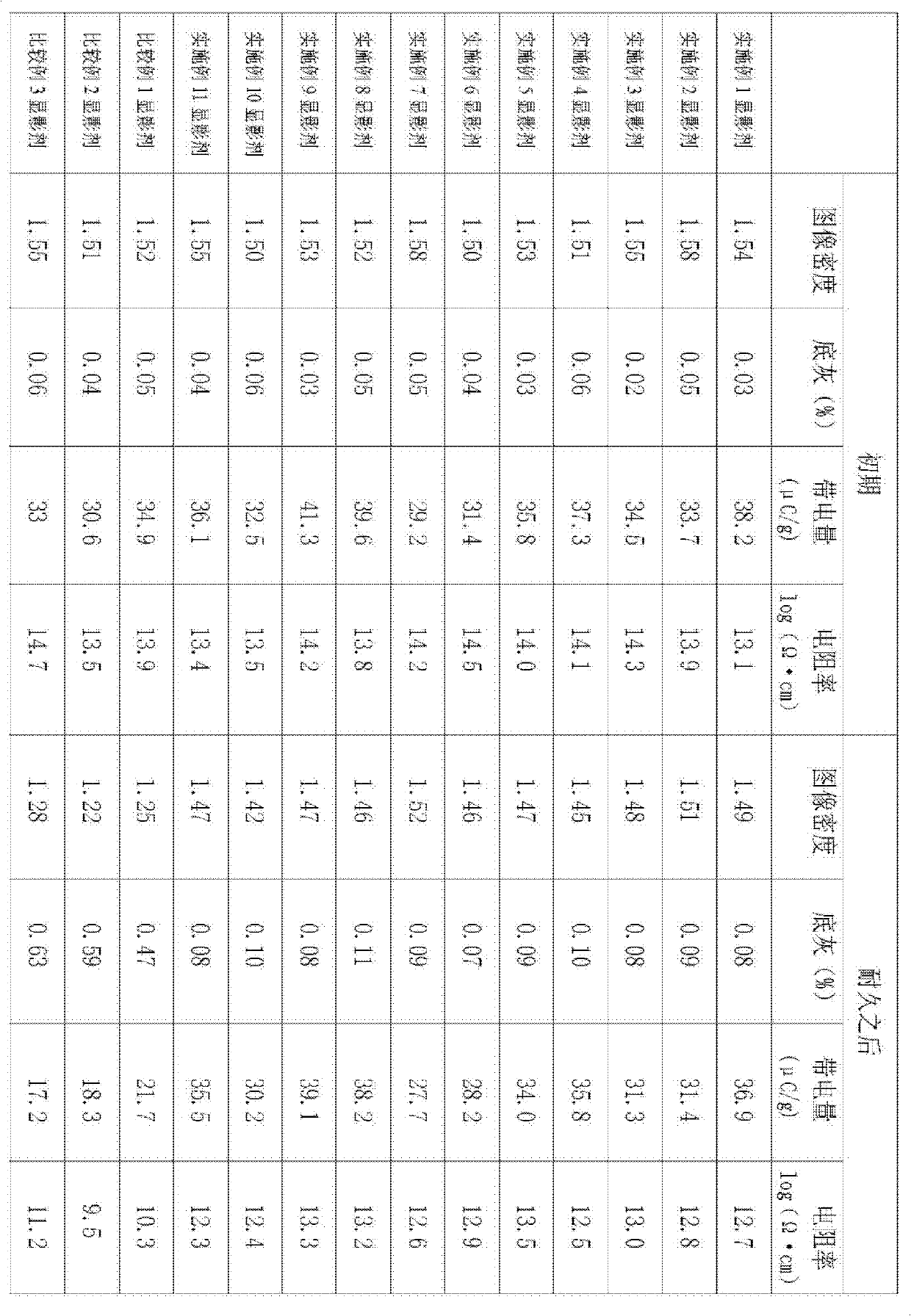

Embodiment 1

[0034]

[0035] 745g Fe 2 o 3 , 218 g Mn 3 o 4 , 24g MgO, 13g SrO are used as the raw material of the carrier core material, dispersed in 820g water, and ground with a ball mill to obtain a mixed slurry of the above substances, in addition, 10g polyacrylic acid is added as a dispersant, and 30g PVA-1788 solution is added as a binding agent agent. The slurry is sprayed into hot air at 250° C. with an airflow or centrifugal spray dryer to obtain dry particles with a particle size of 10-200 μm. The particles were put into an electric furnace and calcined at 800° C. for 2 hours, and the calcined powder was ground again by a ball mill into a slurry of small particles with an average particle diameter of 1 μm. Add the binder PVA, the dispersant polyacrylic acid (the addition amount is the same as above) and spray granulate again with a spray dryer to obtain dry particles with a particle size of 10-200um, and carry out sieving and classification to remove coarse and fine partic...

Embodiment 2

[0042] Except changing the silicone resin of 2 parts by mass into a mixture of 1 part by mass of silicone resin and 1 part by mass of styrene-methyl methacrylate resin, other conditions are basically the same as in Example 1, and the volume average particle diameter obtained is 37.1 μm The carrier particle 2 of Example 2.

Embodiment 3

[0044] Except changing the silicone resin of 2 mass parts into a mixture of 0.4 mass parts of silicone resin and 1.6 mass parts of styrene-methyl methacrylate resin, other conditions are basically the same as in Example 1, and the volume average particle diameter obtained is 37.4 μm Carrier Particle 3 of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com