Biological-selenium-enriched multi-probiotics fermented rice milk and preparation method therefore

A technology of biological selenium and probiotics, which is applied in the field of food processing, can solve the problems of lactic acid bacteria fermentation and growth flavor substances, without considering protein composition and content, etc., to improve starch gelatinization degree and protein utilization rate, improve biological activity and selenium The utilization rate and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 Preparation of biological selenium-rich multi-probiotic fermented rice milk

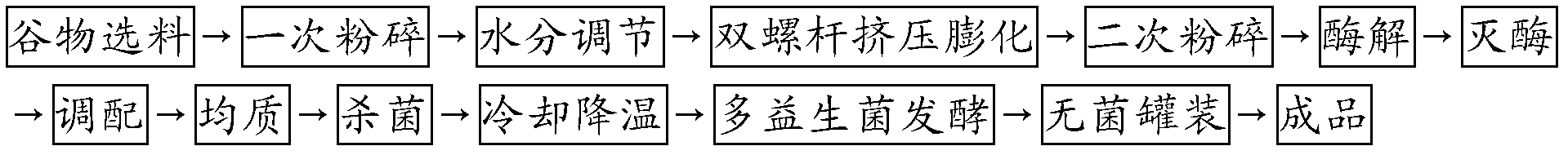

[0057] Process flow chart of the present invention is as image 3 shown.

[0058] Material selection: Select rice, barley, oats and millet without yellow grains, black grains and mildew as raw materials, wash the raw materials with tap water respectively, remove impurities such as rice bran and sand grains, and then dry them in the air. The weight ratio of rice, barley, oats and millet in the raw materials is 3:1:1:2 (w / w).

[0059] One-time pulverization: pulverize the raw materials to 50 mesh with a pulverizer.

[0060] Moisture adjustment: the moisture content of raw materials is controlled at 25%.

[0061] Twin-screw extrusion: process conditions are feeding speed 110r / min, material water addition 15% (w / w), puffing temperature 150°C, and screw speed 240r / min. Under these conditions, the gelatinization degree of extruded grains is 98.55%.

[0062] Secondary crushing: Process...

Embodiment 2

[0071] Example 2 Preparation of biological selenium-rich multi-probiotic fermented rice milk

[0072] Process flow chart of the present invention is as image 3 shown.

[0073] Material selection: Select rice, barley, oats and millet without yellow grains, black grains and mildew as raw materials, wash the raw materials with tap water respectively, remove impurities such as rice bran and sand grains, and then dry them in the air. The weight ratio of rice, barley, oats and millet in the raw materials is 3:1:1:2 (w / w).

[0074] One-time pulverization: pulverize the raw materials to 60 mesh with a pulverizer.

[0075] Moisture adjustment: the moisture content of raw materials is controlled at 30%.

[0076] Twin-screw extrusion: the process conditions are feeding speed 100r / min, material water addition 18% (w / w), puffing temperature 170°C, and screw speed 260r / min. Under these conditions, the gelatinization degree of extruded grains is 98.55%.

[0077] Secondary crushing: Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com