Preparation method for water phase of nitrogen-doped graphene

A nitrogen-doped graphene, water-phase preparation technology, applied in graphene, nano-carbon and other directions, can solve the problems of small specific surface area of the product, high preparation difficulty and high cost, and achieves easy control of the reaction process and simple and easy preparation method. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

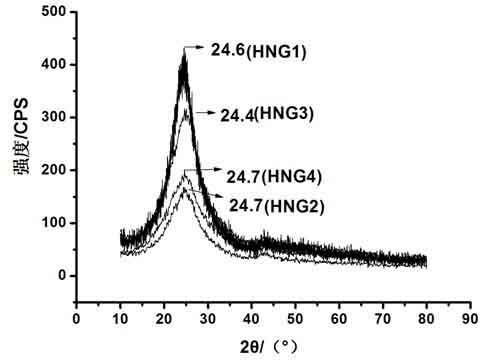

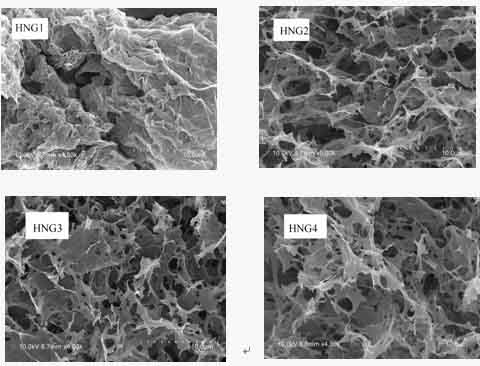

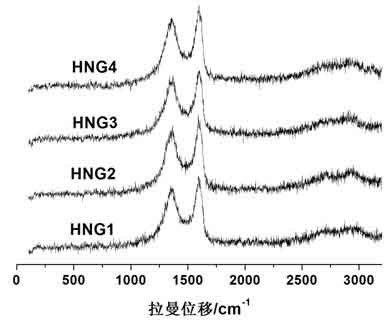

Embodiment 1

[0022] 1) Preparation method of raw material graphene oxide: analyze pure natural graphite powder after pre-oxidation and oxidation by improved Hummers' method (see: 1. Kovtyukhova, N.I.; Ollivier, P.J.; Martin, B.R.; Mallouk, T.E.; Chizhik, S.A.; Buzaneva, E.V.; Gorchinskiy, A.D. Layer-by-Layer Assembly of Ultrathin Composite Films from Micron-Sized Graphite Oxide Sheets and Polycations. Chem. Mater. 1999, 11, 771-778; and 2. Hummers, W.S.; Offeman, R.E.Preparation of Graphic Oxide.J.Am.Chem.Soc.1958, 80, 1339~1339.), filtered and washed, the remaining viscous solid was put into dialysis bags, dialyzed until the pH value was close to neutral, and the obtained product was dried That is graphene oxide. Take 0.0300g of oxidized graphite and ultrasonically disperse it in 20mL of water to make a suspension of oxidized graphene with a concentration of 1.5mg / mL

[0023] 2) Mix and dissolve the oxidized graphene and urea at a mass ratio of 0.3, move it into a stainless steel react...

Embodiment 2

[0025] The preparation method of this example is the same as that of Example 1, but the hydrothermal reaction in step 2 is 150°C for 20 hours. Under the same conditions, a black product is also obtained—nitrogen-doped graphene with a nitrogen doping amount of 5.31 %.

Embodiment 3

[0027] The preparation method of this example is the same as that of Example 1. The mass ratio of the oxidized graphene suspension and urea in step 2 is 0.1. Under the same conditions, a black product is also obtained - nitrogen-doped graphene, nitrogen-doped The amount is 8.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com