Method for removing graphite carbon in nanometer diamond ash prepared by detonation technique

A technology of nano-diamond and graphite carbon, which is applied in the direction of diamond and nanotechnology, can solve the problems of low product purity, many environmental problems, and high equipment requirements, and achieve the effect of simple process, high product purity, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

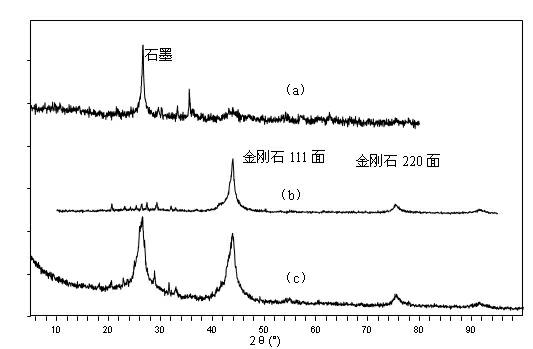

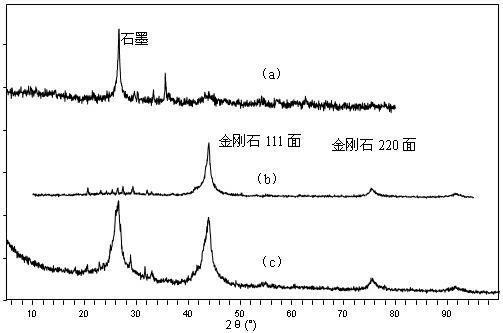

[0009] Embodiment 1: in 50L reactor, put into the 98% sulfuric acid of 6.0kg, add 3.00kg nano-diamond ash material under stirring, be warming up to 110 under vacuum condition o C, add 20.0kg of 40% perchloric acid dropwise, and control the temperature in the kettle to 170-250°C during the dropwise addition o C, 170 after dropping o C for 2 hours, cool to 40 o C, put into 50L deionized water, filter, and fully wash with deionized water until the filtrate is neutral, vacuum-dried to obtain 1.12kg of off-white product of purification, yield 37.3%, the XRD spectrum of the product is shown in figure 1 (b).

Embodiment 2

[0010] Embodiment 2: in 50L reactor, put into the 90% sulfuric acid of 25.5kg, add 3.00kg nano-diamond ash material under stirring, be warming up to 180 under vacuum condition o C, add 15.0kg of 55% perchloric acid dropwise, and control the temperature in the kettle to 170-250°C during the dropwise addition o C, the dropwise addition is completed 210 o C for 6 hours, cool to 40 o C, put into 18L deionized water, filter, and fully wash with deionized water until the filtrate is neutral, and vacuum-dry to obtain 1.07kg of a purified off-white product, with a yield of 35.7%.

Embodiment 3

[0011] Embodiment 3: in 50L reactor, put into the 85% sulfuric acid of 20.0kg, add 3.00kg nano-diamond ash material under stirring, be warming up to 250 under vacuum condition o C, add 10.0kg of 70% perchloric acid dropwise, and control the temperature in the kettle to 170-250°C during the dropwise addition o C, 250 after dropping o C for 10 hours, cool to 40 o C, put into 30L deionized water, filter, and fully wash with deionized water until the filtrate is neutral, and vacuum-dry to obtain 1.09kg of a purified off-white product, with a yield of 36.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com