Adamantane formaldehyde synthetic method suitable for industrial production

The technology of a kind of adamantane formaldehyde and synthesis method is applied in the field of industrial synthesis of adamantane formaldehyde for synthesizing saxagliptin intermediate, which can solve the problems of being unsuitable for industrial production, difficult to operate in industrial production, and harsh reaction conditions, etc., so as to achieve easy separation, The effect of mild reaction conditions and easy access to solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

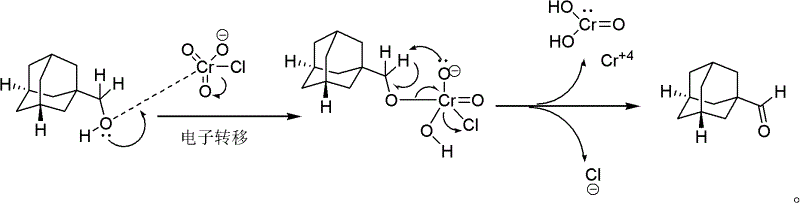

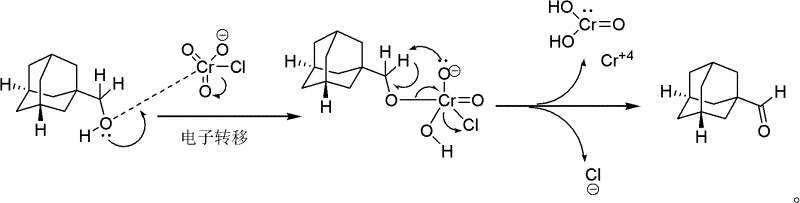

Method used

Image

Examples

Embodiment 1

[0021] Under nitrogen protection, add 1L dichloromethane, 100g adamantane methanol, 168g silica gel, and then add 168g PCC oxidant to a 2L four-necked flask equipped with an electric stirrer, keep the temperature at 20-25°C, react for 3 hours, and filter with suction 100g silica gel and 50g calcium hydroxide were added to the filtrate, stirred at room temperature for 1 hour, suction filtered, and the filtrate was evaporated to dryness under reduced pressure to obtain 75g of adamantane formaldehyde white solid, yield 76%, purity 97% (GC, normalization method) .

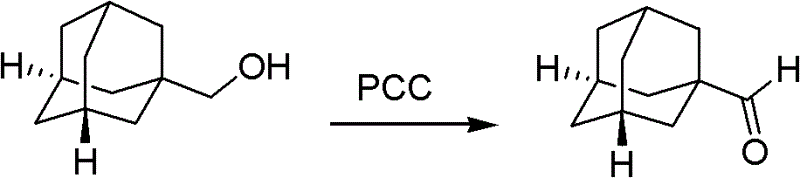

[0022] The reaction formula is as follows:

[0023]

Embodiment 2

[0025] Add 15L of dichloromethane, 1kg of adamantane methanol, 1.5kg of diatomaceous earth into a 50L reaction kettle equipped with an electric stirrer, and then add 1.5kg of PCC oxidant, keep the temperature at 25-30°C, react for 2 hours, and filter with suction. Add 1kg silica gel and 0.8kg calcium hydroxide in the filtrate, stir 1 hour at room temperature, suction filtration, the filtrate is evaporated to dryness under reduced pressure, obtains adamantane formaldehyde white solid 0.8kg, yield 80%, purity 96% (GC, normalized Law).

Embodiment 3

[0027] Add 240kg of dichloromethane into a 300L reactor, add 12kg of adamantane methanol, 20kg of silica gel under stirring, and pass through the jacket with ice brine, lower the liquid temperature to 5-10°C, then add 20kg of PCC oxidant in batches, and react for 1 hour at room temperature , filter, add 12kg silica gel and 6kg calcium hydroxide to the filtrate, keep the temperature at 30-35°C, react for 1 hour under stirring, filter, wash the filtrate with 3% aqueous hydrochloric acid, wash with saturated saline, separate liquid, organic phase The solvent was distilled off under reduced pressure to obtain 8.7 kg of adamantane formaldehyde as a white solid, with a yield of 84% and a purity of 98% (GC, normalization method).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com