Method for preparing sodium dimethyl isophthalate-5-sulfonate from high-concentration fuming sulfuric acid

A technology of dimethyl isophthalate and isophthalic acid, which is applied in the field of preparation of dimethyl isophthalate-5-sodium sulfonate (commonly known as three monomers), can solve the problem of uncontrollable reactions and product side effects. Many products, difficult to handle and other problems, to achieve the effect of improving product yield and quality, reducing the difficulty of refining, and reducing the amount of by-products produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

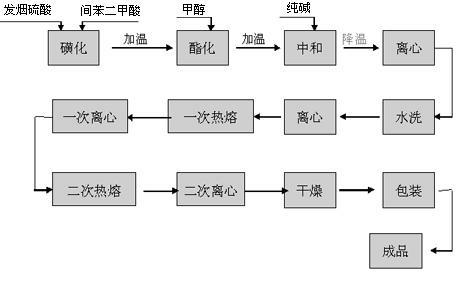

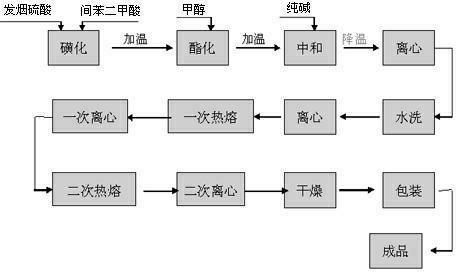

[0026] A method for preparing dimethyl isophthalate-5-sodium sulfonate with high-concentration oleum, comprising the following steps:

[0027] (1) Isophthalic acid and 65% oleum are mixed according to the weight ratio of 1: (0.92-1.08), and the sulfonation reaction is carried out at 150°C for 10 hours, and the reaction between isophthalic acid and SO3 in oleum is produced get sulfonated products;

[0028] (2) Adding methanol to the sulfonated product, and performing an esterification reaction at 50°C for 9 hours to obtain an esterified product; wherein the amount of methanol added is 1.40 times the weight of isophthalic acid;

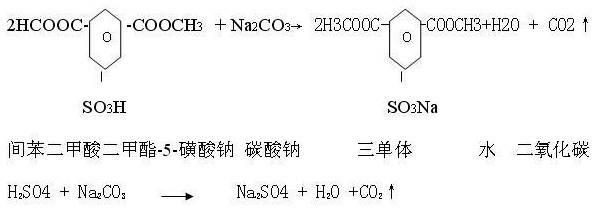

[0029] (3) Add water 6 times the weight of isophthalic acid to the esterification product, and then add soda ash at 20°C to adjust the pH to 5-7.5 to obtain a neutralized material;

[0030] (4) Centrifuge the neutralized material, collect the neutralized mother liquor, then wash the material with water and centrifuge to obtain the crude dimethyl iso...

Embodiment 2

[0032] A method for preparing dimethyl isophthalate-5-sodium sulfonate with high-concentration oleum, comprising the following steps:

[0033] (1) Isophthalic acid and 65% oleum were mixed in a weight ratio of 1: (0.92-1.08), and sulfonated at 220°C for 8 hours to obtain a sulfonated product;

[0034] (2) Adding methanol to the sulfonated product, and performing an esterification reaction at 90°C for 6 hours to obtain an esterified product; wherein the amount of methanol added is 1.16 times the weight of isophthalic acid;

[0035] (3) Add water 6 times the weight of isophthalic acid to the esterification product, and then add soda ash at 55°C to adjust the pH to 5-7.5 to obtain a neutralized material;

[0036] (4) Centrifuge the neutralized material, collect the neutralized mother liquor, then wash the material with water and centrifuge to obtain the crude dimethyl isophthalate-5-sodium sulfonate, and collect the washed mother liquor; then add the crude isophthalic acid So...

Embodiment 3

[0038] Treat the neutralization mother liquor described in Example 1 through the following process: add 2-4 times the volume of methanol to the neutralization mother liquor, adjust the pH of the mixture to 4.5-5.5, and perform extraction and conversion reactions at a temperature of 50°C , the reaction time is 9 hours, sodium sulfate is precipitated, and the monomethyl isophthalate-5-sodium sulfonate and isophthalic acid-5-sodium sulfonate in the mother liquor are converted into dimethyl isophthalate-5- Sodium sulfonate (three monomers); then solid sodium sulfate is separated by solid-liquid separation, and the remaining liquid material is extracted by continuous distillation to methanol, and then solid sodium sulfate is separated by solid-liquid separation. The liquid material separated from sodium sulfate enters the continuous rectification tower, and methanol is extracted through rectification, and the methanol is returned to step (2) for reuse in the esterification process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com