Method for preparing pectin oligosaccharide (POS) through dynamic high-pressure microfluidization (DHPM) combined acid process

A technology of high-pressure micro-jet and pectin oligosaccharides, which is applied in the preparation of oligosaccharides and the field of beneficial activities of oligosaccharides, can solve the problems of low yield of oligomers, high ash content, and many colored substances, and achieve Good probiotic activity, short reaction time, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

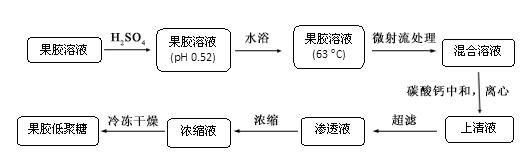

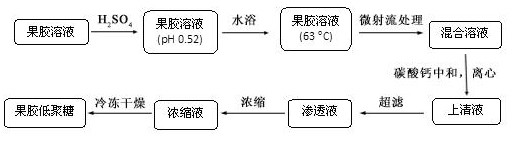

Method used

Image

Examples

Embodiment 1

[0020] Weigh 18.4g pectin and dissolve it in 1000ml distilled water, stir at room temperature until completely dissolved, and use 0.5MH 2 SO 4 Adjust the pH of the solution to H in the pectin solution 2 SO 4 The concentration is 0.15 M, and the water bath is heated to 63 o c. Add the heated pectin solution into the micro jet, and treat it under 160MPa for 6 times to get the degraded pectin solution. Add 10% pectin solution calcium carbonate powder to the pectin solution, stir well, centrifuge, and take the supernatant. The supernatant was ultrafiltered for 6 h in a tangential flow ultrafilter with a molecular weight cut off of 5,000 Da, and the permeate was collected and concentrated. Put the permeate at -80 o Freeze-drying under C conditions for 48 hours to obtain pectin oligosaccharides. Inoculate Bifidobacterium, Lactobacillus, and Escherichia coli in 10 ml minimal medium with 1% (w / v) glucose as carbon source, 37 o C Cultivate for 24 hours under anaerobic condit...

Embodiment 2

[0022] Weigh 36.8 g pectin and dissolve it in 1000 ml distilled water, stir at room temperature until completely dissolved, and use 0.5MH 2 SO 4 Adjust the pH of the solution to H in the pectin solution 2 SO 4 The concentration is 0.15 M, and the water bath is heated to 63 o c. Add the heated pectin solution into the micro jet, and treat it under 160MPa for 6 times to get the degraded pectin solution. Add 10% pectin solution calcium carbonate powder to the pectin solution, stir well, centrifuge, and take the supernatant. The supernatant was ultrafiltered for 6 h in a tangential flow ultrafilter with a molecular weight cut off of 5,000 Da, and the permeate was collected and concentrated. Put the permeate at -80 o Freeze-drying under C conditions for 48 hours to obtain pectin oligosaccharides. Inoculate Bifidobacterium, Lactobacillus, and Escherichia coli in 10 ml minimal medium with 1% (w / v) glucose as carbon source, 37 o C Cultivate for 24 hours under anaerobic cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com