Probiotic active compound polysaccharide as well as preparation method and application thereof

A compound polysaccharide and living technology, applied in the direction of application, polysaccharide/gum-containing food ingredients, food ingredients as odor improvers, etc., can solve the adverse effects of product color and odor, improve intestinal microorganisms without prebiotics, and study probiotics Less problems such as polysaccharide browning degree is not high, facility requirements are not high, and the effect of reducing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

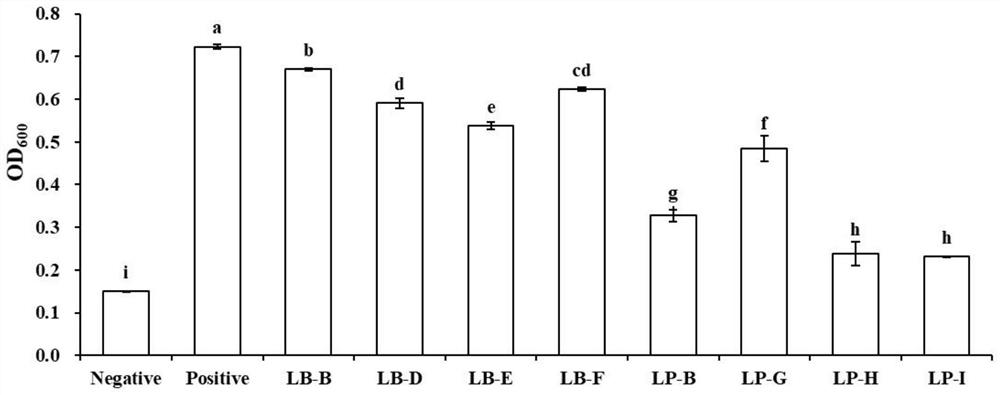

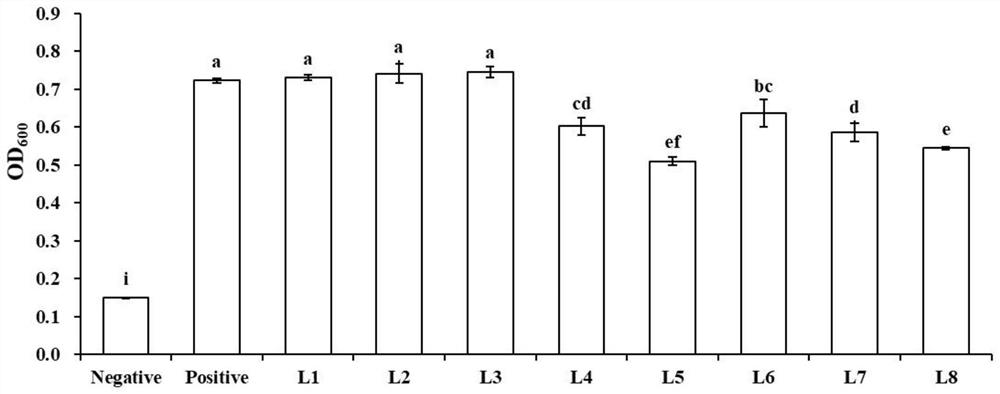

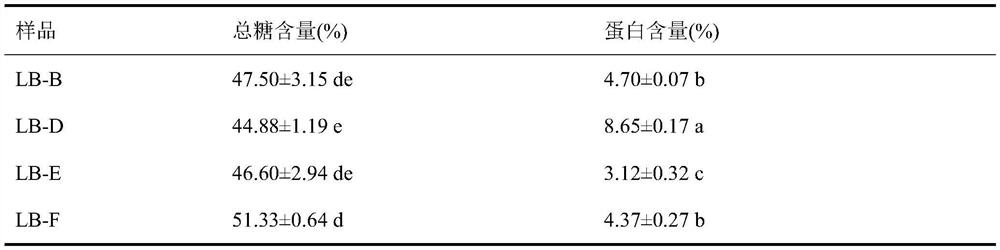

Examples

preparation example Construction

[0063] (1) Preparation of standard products: equal volume of 8 monosaccharide standard products (10 mg / mL, solvent For ultrapure water) 20μL in a stoppered test tube, mix well, as a mixed standard. Pipette 50μL of mixed standard into a stoppered test tube, add 50μL of 0.6mol / L NaOH aqueous solution, and 100μL of 0.5mol / L 1-phenyl-3-methyl-5-pyrazolone (PMP) methanol solution. The derivatization reaction was carried out at 70 °C for 100 min and cooled. Add 100 μL of 0.3 mol / L HCl solution, make up with water until the final volume is 2 mL, add 2 mL of chloroform, mix well, centrifuge at 2000 rpm for 5 min, discard the chloroform phase, repeat the extraction 6 times, take the aqueous phase through a 0.22 μm microporous membrane, and wait for HPLC sample analysis.

[0064] (2) Sample preparation: Take 1 mL of 10 mg / mL sample solution into an ampoule bottle, add 1 mL of 4 mol / L trifluoroacetic acid aqueous solution, seal, and hydrolyze at 110 °C for 8 h; take out and cool, add 4...

Embodiment 1

[0070] A preparation method of probiotic composite polysaccharide, specifically comprising the following steps:

[0071] The extraction conditions of Lycium barbarum polysaccharide for compounding are as follows:

[0072] (1) Lycium barbarum homogenate to remove impurities: Weigh 60g of dry wolfberry, add 70% (v / v) ethanol aqueous solution according to the ratio of material to liquid 1:6g / mL, pass through colloid mill twice, at a stirring speed of 120r / min and a temperature of 80 Under the condition of ℃, reflux extraction for 1h, centrifuge under the conditions of centrifugal force of 6000g and centrifugation time of 15min, discard the supernatant, recover the residue, repeat the extraction according to the above steps, the drying temperature of the recovered residue is 50℃, and the drying time is 10h , get residue A1;

[0073] (2) Enzymatic hydrolysis: 18 g of residue A1 was added to deionized water at a ratio of 1:20 g / mL of material to liquid, and 0.6% by mass of residue ...

Embodiment 2

[0094] A preparation method of probiotic composite polysaccharide, specifically comprising the following steps:

[0095] The extraction conditions of Lycium barbarum polysaccharide for compounding are as follows:

[0096] (1) Lycium barbarum homogenate to remove impurities: weigh 60g of dry wolfberry, add 80% (v / v) ethanol aqueous solution according to the material-to-liquid ratio of 1:8 g / mL, and pass through colloid mill 3 times at a stirring speed of 150r / min and a temperature of 85 Under the condition of ℃, reflux extraction for 1.5h, centrifuge under the conditions of centrifugal force of 7000g and centrifugation time of 20min, discard the supernatant, recover the residue, repeat the extraction twice according to the above steps, the drying temperature of the recovered residue is 55℃, and the drying time 11h, get residue B1;

[0097] (2) Enzymatic hydrolysis: 18 g of residue B1 was added to deionized water at a ratio of 1:30 g / mL of material to liquid, and at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com