Polyvinylidene difluoride-trifluoroethylene/ nickel doped titanium dioxide composite film

A technology of composite film and polyvinylpyrrolidone, applied in the direction of capacitor parts, etc., can solve the problems of low dielectric constant, brittleness, and high price, achieve good flexibility and dielectric properties, simple preparation process, and improve dielectric properties constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

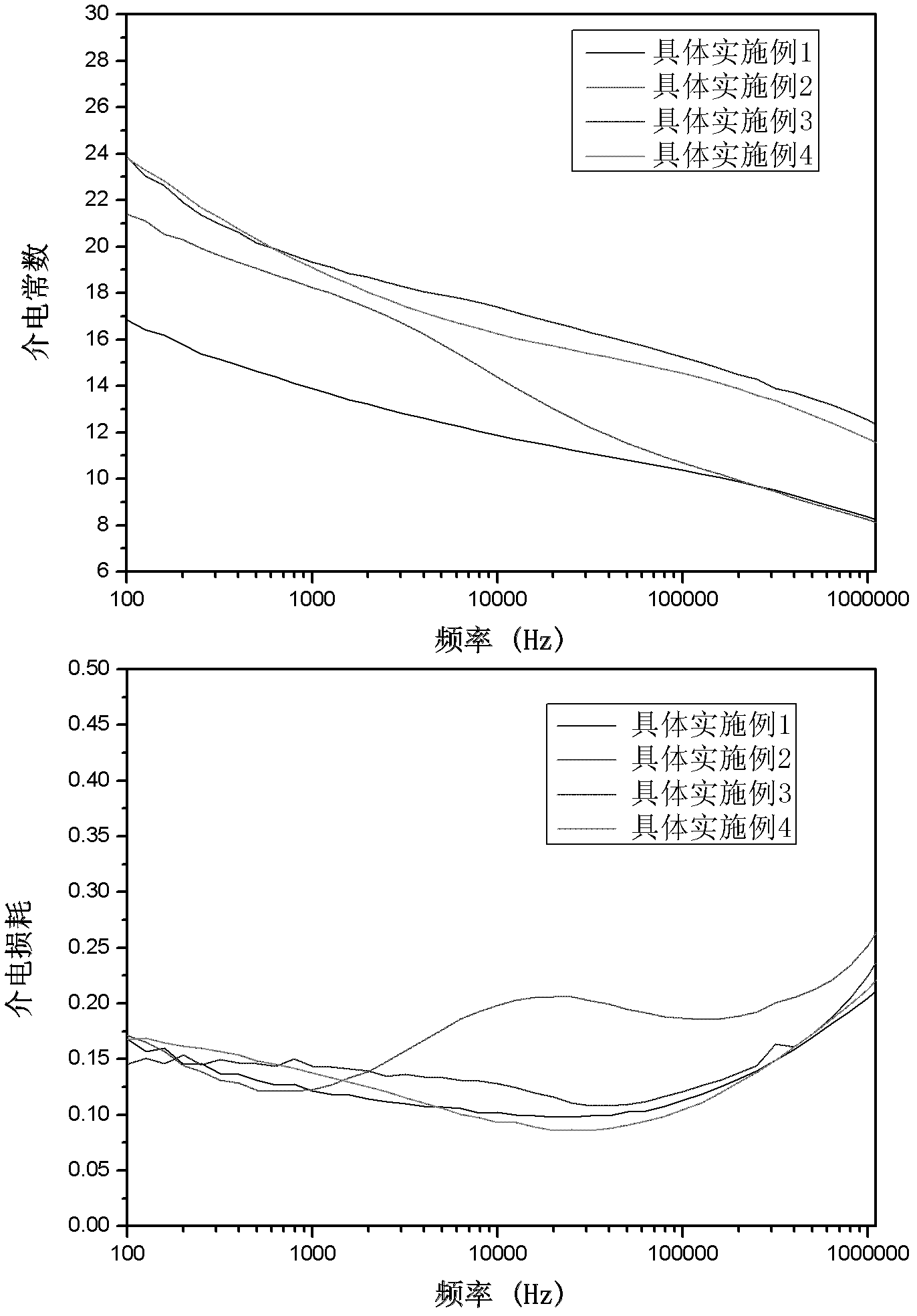

specific Embodiment 1

[0022] Specific embodiment 1: comparative test

[0023] PVDF-TrFE / Ni-TiO of the present embodiment 2 The organic-inorganic composite film is composed of the following components by mass percentage: PVDF-TrFE: 10wt%, Ni-TiO 2 Powder: 0wt%, crosslinking agent PVP: 0.1wt%, organic solvent DMF: 89.9wt%.

specific Embodiment 2

[0024] Specific example 2: PVDF-TrFE / Ni-TiO of the present embodiment 2 The organic-inorganic composite film is composed of the following components by mass percentage: PVDF-TrFE: 10wt%, Ni-TiO 2 Powder: 0.5wt%, crosslinking agent PVP: 0.1wt%, organic solvent DMF: 89.4wt%.

[0025] Nano-Ni-TiO 2 Powder preparation process:

[0026] a. Dissolve 5g of tetrabutyl titanate in absolute ethanol and stir for 30 minutes; what are the requirements for the amount of tetrabutyl titanate added;

[0027] b. Add 3.8ml of concentrated hydrochloric acid and 1g of crosslinking agent dropwise to the solution described in step a under stirring conditions, and stir for 1h after the addition is complete;

[0028] c. Add the mixed solution of 0.426g of nickel nitrate and 40ml of absolute ethanol dropwise to the solution described in step b under stirring condition, and stir for 2h after the dropwise addition is completed;

[0029] d, adjust the pH of the solution described in step c to 7 with a...

specific Embodiment 3

[0034] Specific example 3: PVDF-TrFE / Ni-TiO of the present embodiment 2 The organic-inorganic composite film is composed of the following components by mass percentage: PVDF-TrFE: 10wt%, Ni-TiO 2 Powder: 2wt%, crosslinking agent PVP: 0.1wt%, organic solvent DMF: 87.9wt%. The molar ratio of PVDF to TrFE in the PVDF-TrFE is 70:30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com