Fragrant chinlon masterbatch, fragrant chinlon fiber and preparation methods thereof

A nylon fiber and nylon technology, applied in the field of scented nylon fiber and its preparation, can solve the problems of intensified market competition, production capacity and quality gap, etc., and achieve the effect of high added value of products, low production cost, and no pollution of fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

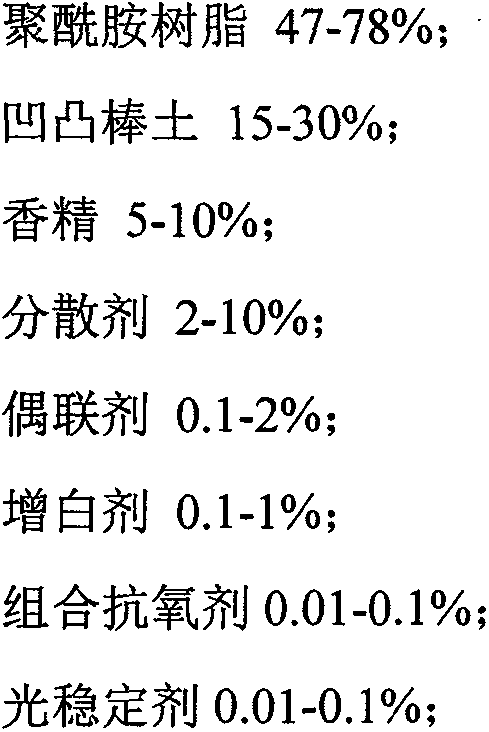

[0022] The weight percentage formula of scented nylon masterbatch is:

[0023] Polyamide 6 resin 54%;

[0024] Attapulgite 25%;

[0025] Fragrance 10%;

[0026] Dispersant 10%;

[0027] Coupling agent 1%;

[0028] Brightener 0.1%;

[0029] Combined antioxidant 0.01%;

[0030] Light stabilizer 0.01%;

[0031] The preparation method of scented nylon masterbatch is as follows: roast 1000-mesh attapulgite at 300°C for 1 hour, cool to room temperature, add high-temperature-resistant rubber and plastic flavor evenly according to the above formula ratio, and then add whitening agent, MD697 / Thiodipropionate combined antioxidant, 783 light stabilizer, polyamide wax dispersant and aluminum-titanium composite coupling agent are added, kneaded in a kneading pot at a temperature of 140°C until coated, and granulated to make a mixed material, and then mixed with polyamide 6 resin evenly, put into a twin-screw extruder for mixing, extruding, and granulating to obtain fragrance nylon ...

Embodiment 2

[0034] The weight percentage formula of scented nylon masterbatch is:

[0035] Polyamide 66 resin 78%;

[0036] Attapulgite 15%

[0037] Flavor 5%;

[0038] Dispersant 2%;

[0039] Coupling agent 0.1%;

[0040] Brightener 0.1%;

[0041] Combined antioxidant 0.01%;

[0042] Light stabilizer 0.01%;

[0043] The preparation method of scented nylon masterbatch is as follows: roast 1000-mesh attapulgite at 200°C for 1 hour, cool to room temperature, add high-temperature-resistant rubber and plastic flavor evenly according to the above formula ratio, and then add whitening agent, MD697 / Phosphite combined antioxidant, 783 light stabilizer, stearic acid dispersant and titanate coupling agent were added, kneaded in a kneading pot at a temperature of 150°C until it was coated, granulated to make a mixture, and then Mix evenly with polyamide 66 resin, put it into a twin-screw extruder for mixing, extrude, and granulate to obtain fragrance nylon masterbatch; the temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com