Method for preparing high-purity tea polyphenol in centrifuging, extracting and separating mode

A centrifugal extractor and tea polyphenol technology, applied in the field of separation, can solve the problems of low yield of active ingredients, heavy metal residues in products, high energy consumption, etc., achieve high catechin content and EGCG content, separation efficiency and production efficiency The effect of high height and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Weigh 50g of tea leaves, add 500ml of deionized water (90°C) to extract for 45 minutes, take out the extract solution; then add 300ml of deionized water (90°C) to extract for 45 minutes; combine the extracts, and pump through a 300-mesh filter cloth Filtration and 0.2um ceramic membrane treatment to obtain tea polyphenol microfiltrate.

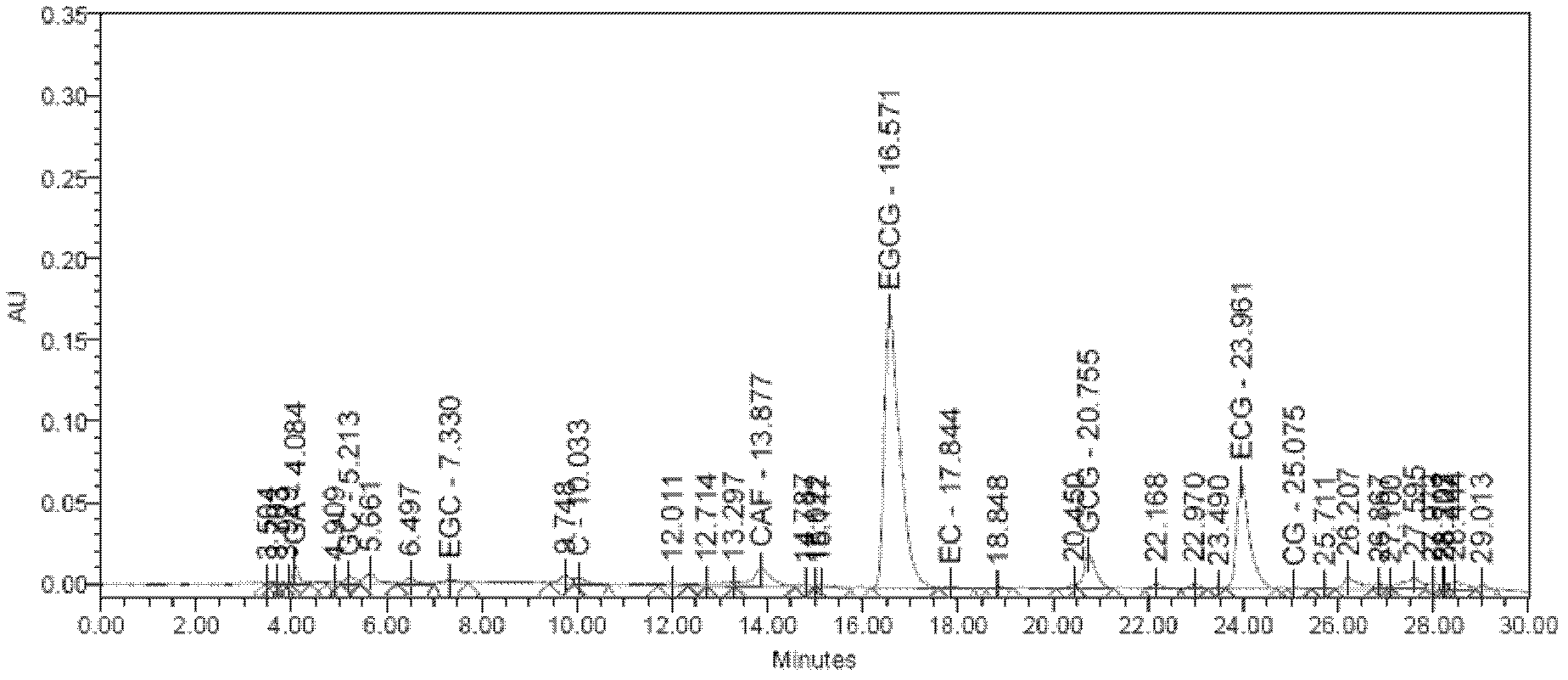

[0014] Pump the tea polyphenol microfiltrate into the first-stage centrifugal extractor, and at the same time pump an equal volume of dichloromethane solvent, turn on the centrifugal extractor at a speed of 3000rpm; then pump the extracted and separated solution into the second-stage centrifugal extractor, and simultaneously Pump in an equal volume of ethyl acetate solvent, turn on the centrifugal extractor at a speed of 3000rpm; collect and combine the ethyl acetate phase solution, concentrate in a vacuum, and spray dry to obtain high-purity tea polyphenols, in which the purity of tea polyphenols is 97.35%, and caffeine Content 0.84%. ...

Embodiment 2

[0016] Weigh 500g of tea leaves, add 5000ml of deionized water (80°C) to extract for 35 minutes, take out the extract; then add an equal volume of deionized water (80°C) to extract for 35 minutes; combine the extracts, pass through a 200-mesh filter cloth Suction filtration and 0.15um ceramic membrane treatment to obtain tea polyphenol microfiltrate.

[0017] Pump the tea polyphenol microfiltrate into the first-stage centrifugal extractor, and at the same time pump an equal volume of dichloromethane solvent, turn on the centrifugal extractor at a speed of 2500rpm; then pump the extracted and separated solution into the second-stage centrifugal extractor, and simultaneously Pump in an equal volume of ethyl acetate solvent, turn on the centrifugal extractor at a speed of 2500rpm; collect and combine the ethyl acetate phase solution, vacuum concentrate and spray dry to obtain high-purity tea polyphenols, wherein the purity of tea polyphenols is 95.67%, and caffeine Content 0.96%....

Embodiment 3

[0019] Weigh 1000g tea leaves, add 10000ml deionized water (95℃) for extraction for 45 minutes, take out the extract solution; then add 5000ml deionized water (95℃) for extraction for 45 minutes; then add 3000ml deionized water (95℃) for extraction Extract for 30 minutes; combine the extracts, filter through a 250-mesh filter cloth, and treat with a 0.10um ceramic membrane to obtain a tea polyphenol microfiltrate.

[0020] Pump the tea polyphenol microfiltrate into the first-stage centrifugal extractor, and at the same time pump an equal volume of dichloromethane solvent, turn on the centrifugal extractor at a speed of 5000rpm; then pump the extracted and separated solution into the second-stage centrifugal extractor, and simultaneously Pump in an equal volume of ethyl acetate solvent, turn on the centrifugal extractor at a speed of 5000rpm; collect and combine the ethyl acetate phase solution, concentrate in a vacuum, and spray dry to obtain high-purity tea polyphenols, in whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com