Preparation method of lithium iron phosphate precursor

A lithium ferrous phosphate and precursor technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as poor batch consistency and large-scale production, achieve good batch consistency, improve product purity and consistency good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Raw material ratio: lithium dihydrogen phosphate LiH 2 PO 4 6.59kg, iron nitrate Fe (NO 3 ) 39 h 2 O25.61kg, glucose C 6 h 12 o 6 .H 2 O 2.09kg.

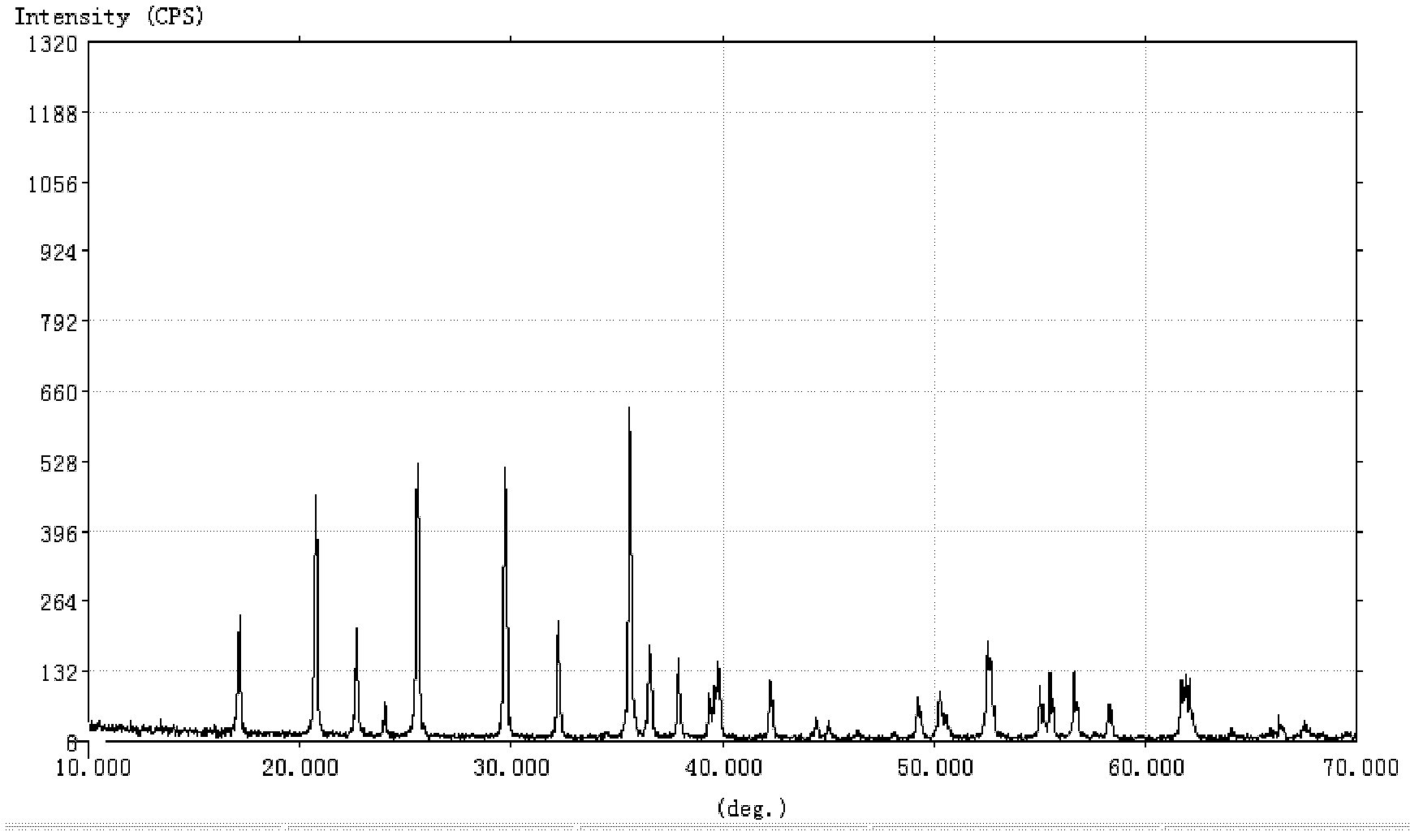

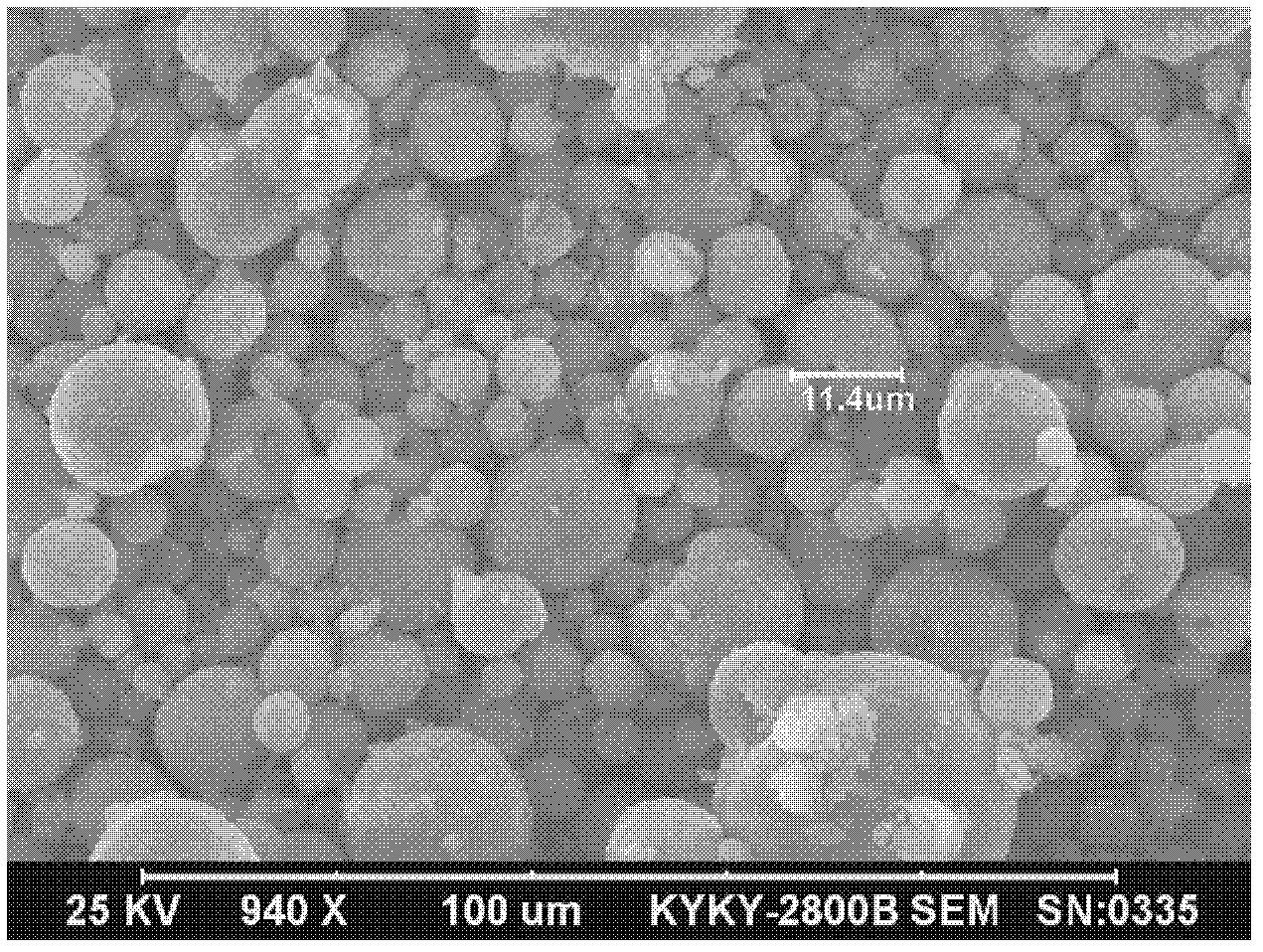

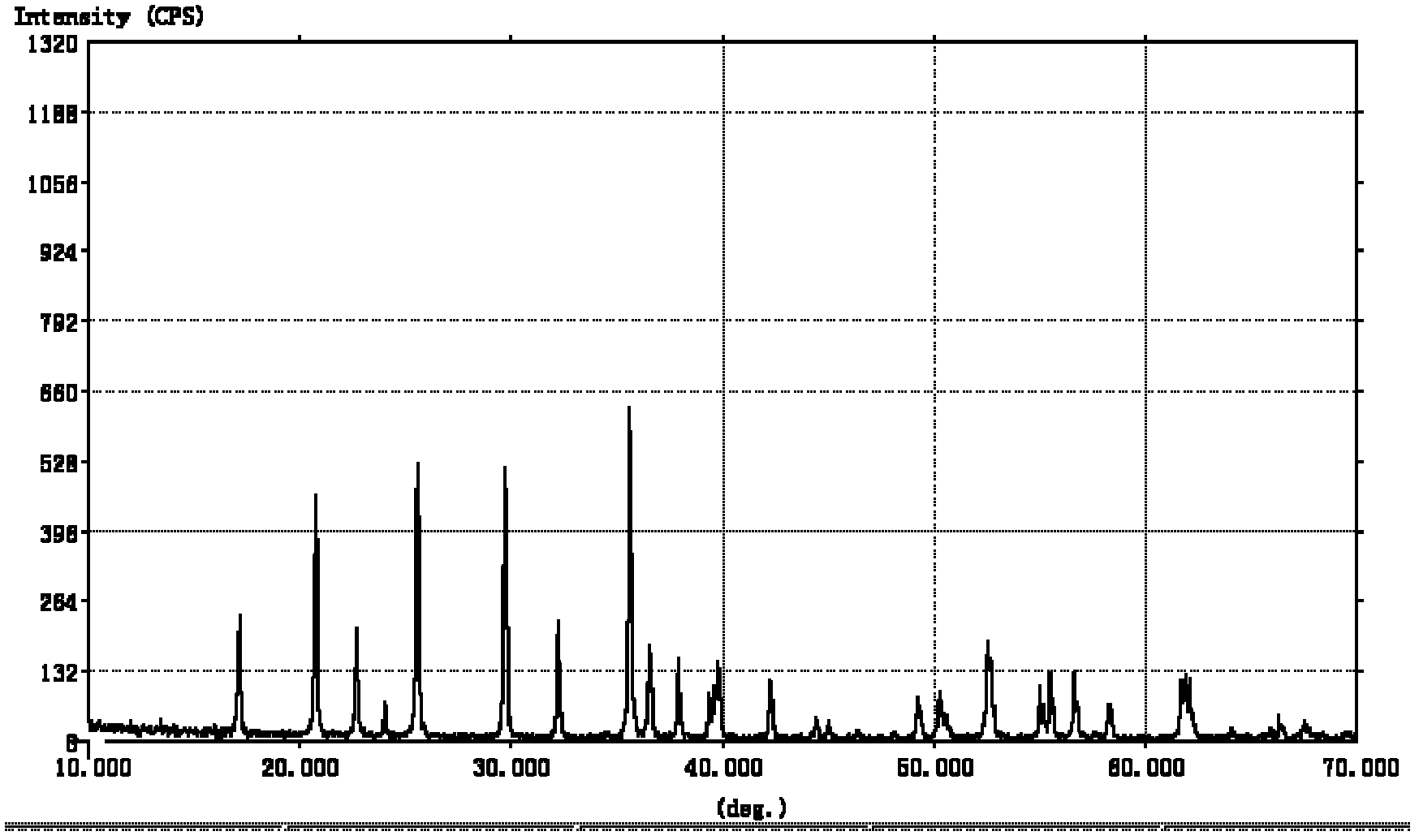

[0018] Preparation method: Dissolve lithium dihydrogen phosphate, ferric nitrate, and glucose in deionized water according to the above ratio, and stir for about 1 hour to completely dissolve. Then the fully dissolved solution is spray-dried and granulated, and the drying temperature is controlled at about 350°C, so as to obtain a spherical precursor powder with a controllable particle size. Then put the spherical precursor powder into a program-controlled heating furnace, protect it with high-purity nitrogen, and calcinate at 670±5°C for 10-12 hours at a heating rate of 4.5-5.5°C / min, and then at a cooling rate of 4-5°C / min. min is cooled to room temperature with the furnace and taken out to obtain capacity-type LiFePO4 products.

Embodiment 2

[0020] Raw material ratio: lithium dihydrogen phosphate LiH 2 PO 4 6.653kg, iron nitrate Fe(NO3)39H 2 O24.56kg, magnesium nitrate Mg (NO 3 ) 2 .2H 2 O 0.59kg, glucose C 6 h 12 o 6 .H 2 O 2.0kg.

[0021] Preparation method: Dissolve lithium dihydrogen phosphate, iron nitrate, magnesium nitrate, and glucose in deionized water according to the above ratio, and stir for about 1 hour to completely dissolve. Then the fully dissolved solution is spray-dried and granulated, and the drying temperature is controlled at about 300°C to obtain a spherical precursor powder with a controllable particle size. Then put the spherical precursor powder into a program-controlled heating furnace, protect it with high-purity nitrogen, and calcinate at 750±5°C for 8-10 hours at a heating rate of 7-8°C / min, and then at a cooling rate of 6-7°C / min. min Cool down to room temperature with the furnace and take it out, you can get the rate type LiFe 095 Mg 0.05 PO 4 product.

Embodiment 3

[0023] Raw material ratio: lithium dihydrogen phosphate LiH 2 PO 4 6.64kg, iron nitrate Fe (NO 3 ) 39 h 2 O24.77kg, magnesium nitrate Mg (NO 3 ) 2 .2H 2 O 0.47kg, glucose C 6 h 12 o 6 .H 2 O2.021kg.

[0024] Preparation method: same as Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com