Method and device for removing phosphorous from glyphosate production wastewater

A technology for the production of wastewater and glyphosate, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient phosphorus removal in wastewater, unfavorable enterprise costs, consumption of hydrogen peroxide, etc. problem, to avoid the effect of excessive local concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

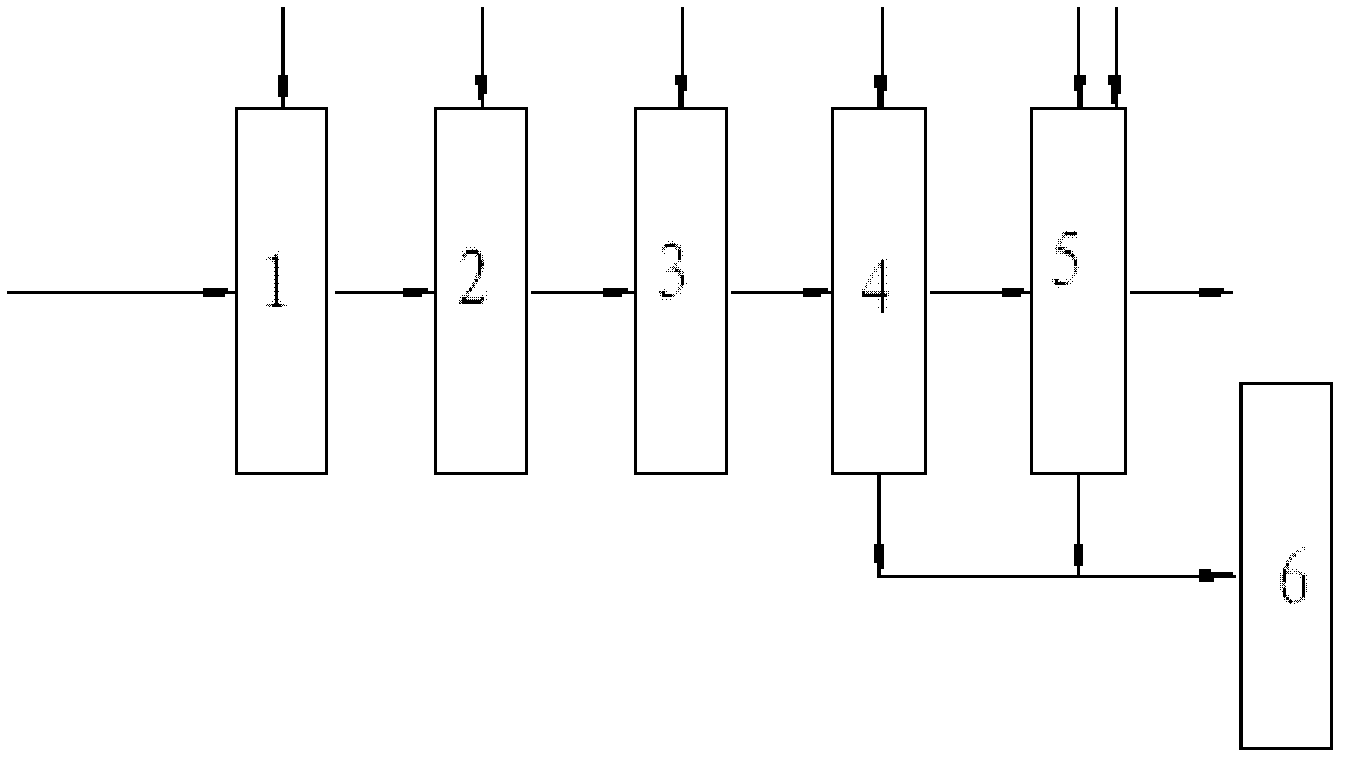

Image

Examples

Embodiment 1

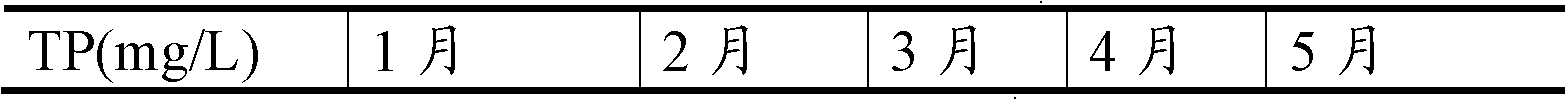

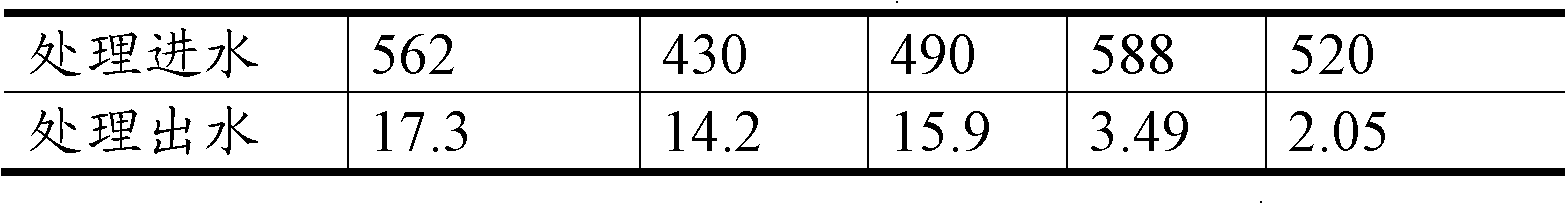

[0036] The effluent from a company's glyphosate production site has a high concentration of organic phosphorus, poor biodegradability, and difficult treatment. The composition of water quality and quantity is shown in Table 1.

[0037] Table 1 Water quality analysis table of glyphosate wastewater

[0038] name of waste water

Wastewater volume (t / d)

COD (mg / L)

TP (mg / L)

Floor washing wastewater

200

3000

2500

Melting wastewater

80

≤10

150

Sanhua Tail Gas Absorption Wastewater

40

≤10

1700

Mother liquor concentrated condensate wastewater

240

650

150

Belt filter press for flushing waste water

80

400

40

Dimethyl ester synthesis wastewater

200

1500

40

Chloromethane washing wastewater

200

2000

≤1

Finished product warehouse wastewater

200

400~700

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com