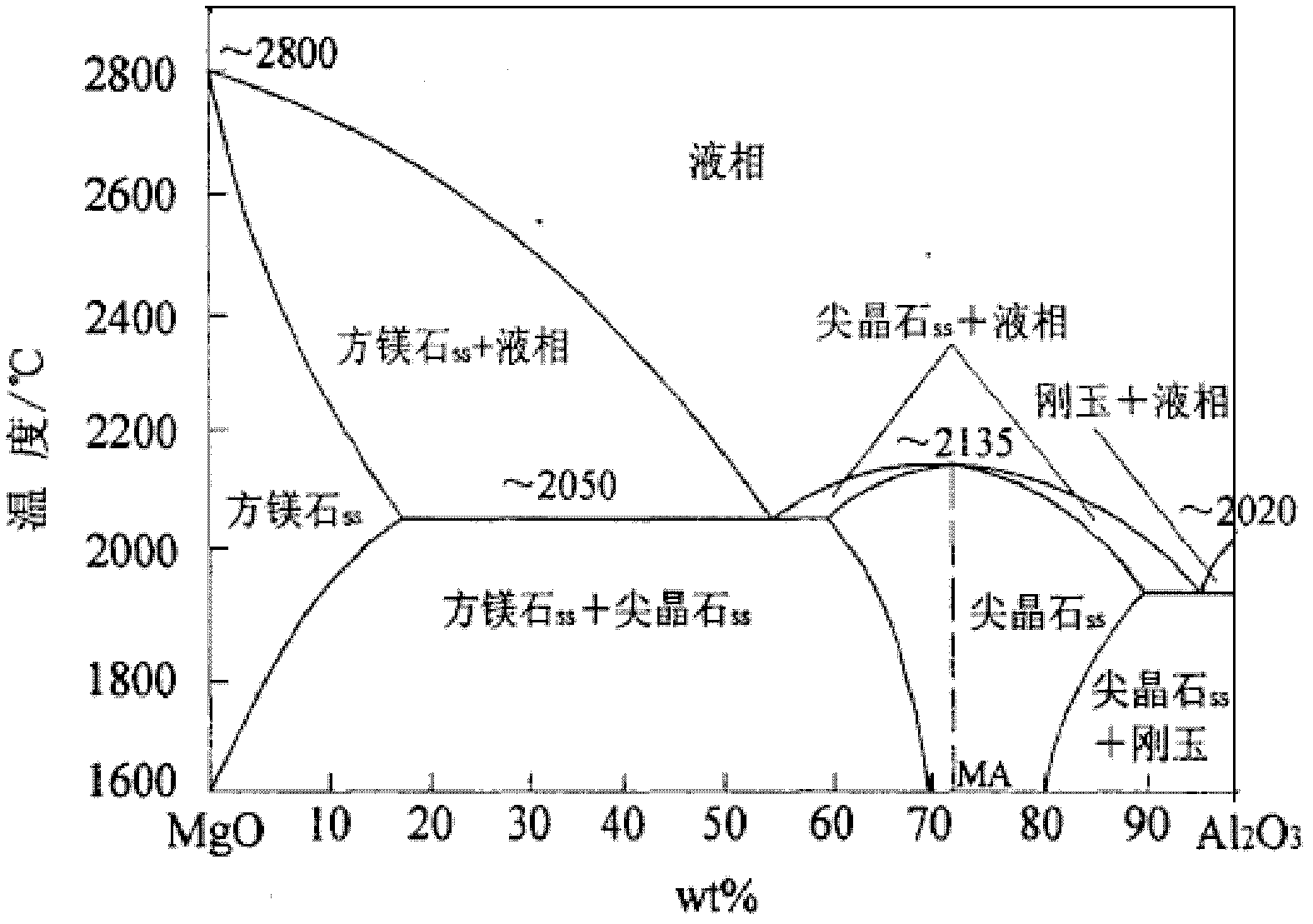

Aluminum-spinel-corundum composite refractory material and preparation method as well as application thereof

A refractory material, magnesium aluminum spinel technology, applied in the field of aluminum-spinel-corundum composite refractory materials and its preparation, can solve the problems of reduced durability, reduce energy consumption, enhance corrosion resistance, reduce resistance The effect of material waste and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

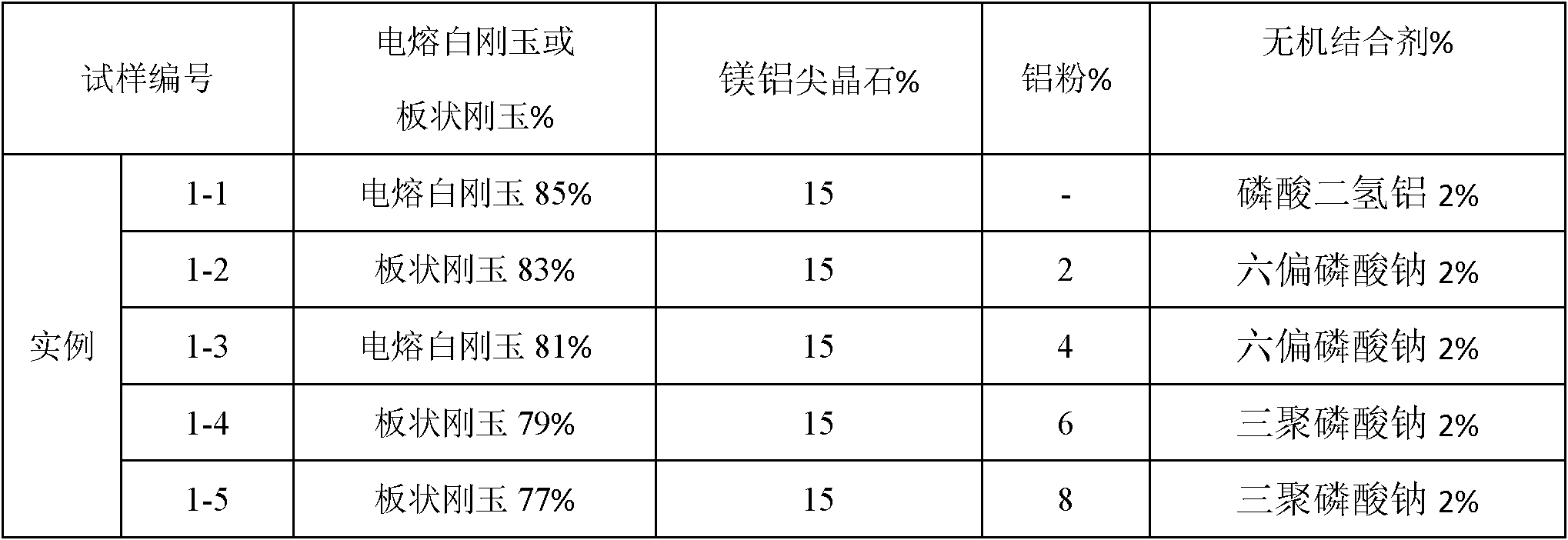

Embodiment 1

[0036] The raw materials are weighed according to the formula in Table 2, and the particle size gradation of each raw material is as follows:

[0037] 4-1mm coarse particle size 45~50wt%;

[0038] 15-25wt% of particles with a medium size of 1-0.088mm;

[0039] ≤0.088mm fine powder 30~35wt%.

[0040] The aluminum-spinel-corundum composite refractory samples were prepared as follows:

[0041] Aluminum-spinel-corundum composite refractory

[0042] (1) ingredients: weigh the required raw materials according to the proportioning in Table 2;

[0043] (2) Kneading: premix the raw material fine powder with a size of ≤0.088mm for 25-35min, pour the raw material (ie aggregate) with a particle size larger than 0.088mm into the roller mill and mix evenly, stop stirring after 15min, and combine the inorganic Pour in half of the agent, continue stirring for 15min, pour the pre-mixed fine powder into the roller mill and stir for 15min, then pour all the remaining binder and continue stir...

Embodiment 2

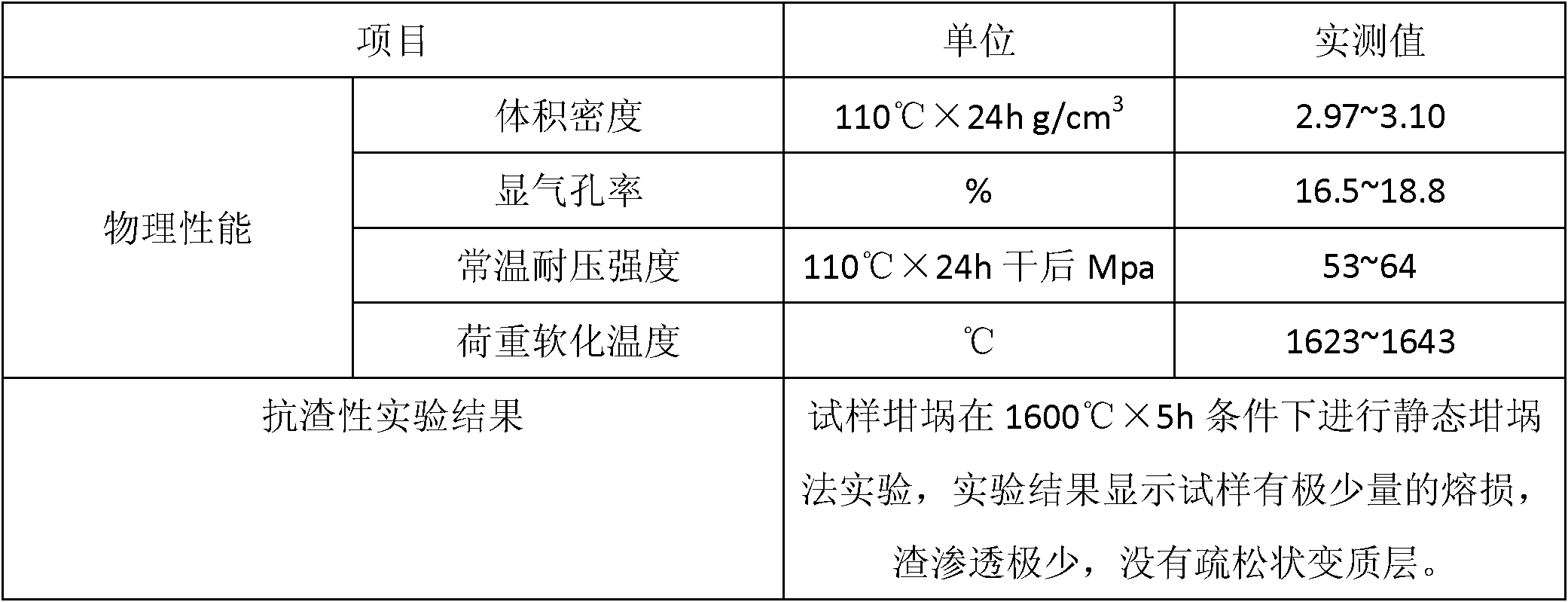

[0055] The preparation method is the same as that of Example 1, and the aluminum-spinel-corundum composite refractory is produced according to the formula shown in Table 4, and the routine physical and chemical property testing is shown in Table 5.

[0056] Table 4

[0057]

[0058] table 5

[0059]

[0060] It can be seen from Table 5 that the apparent porosity of the material is relatively low when the spinel content is 15-20%, but the difference is not significant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com