High temperature resistant epoxy-imine resin adhesive and preparation method thereof

An imine resin, epoxy resin technology, applied in epoxy resin glue, adhesive, non-polymer adhesive additive and other directions, can solve problems such as unfavorable market promotion, achieve good controllability, realize industrialized production, source handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

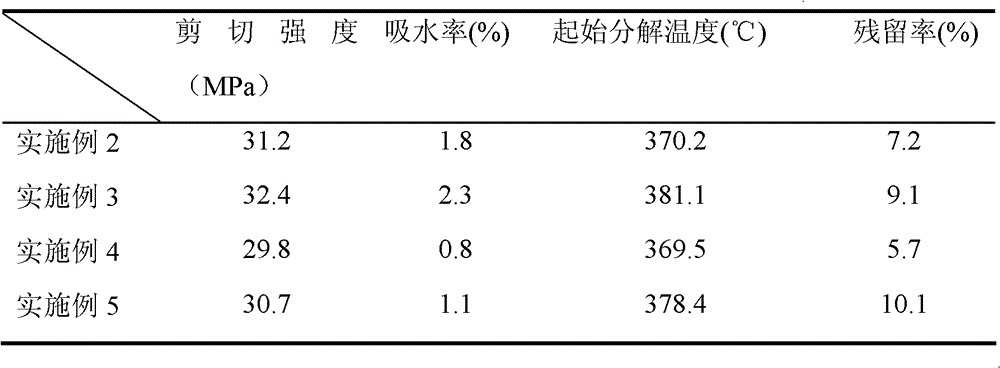

Examples

Embodiment 1

[0025] Add 0.1 mole (29.0 g) of 4,4'-diamino-4"-hydroxytriphenylmethane (DATHM) and 300 ml of N,N-dimethylacetamide into the polymerization bottle, stir to dissolve, add 0.2 mole (38.4 grams) of trimellitic anhydride (TMA) powder, reacted at room temperature for 0.5 hours, to obtain a transparent homogeneous solution, add 100 milliliters of toluene, carry out heating azeotropic dehydration, until the system azeotropic dehydration is complete, subsequently, the system is concentrated by heating distillation To about 1 / 5, 62.3 grams of hydroxycarboxyl-terminated imide (CPI-DAHTM) powder was prepared in acetone, with a yield of 97.7%.

Embodiment 2

[0027] Preparation process: put bisphenol A epoxy resin and hydroxyl-containing carboxy-terminated imide (CPI-DAHTM) into a reaction bottle, stir and heat to 90°C, react to a homogeneous and transparent state, cool to 50°C, add N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane (TGDDM), reactive diluent and curing agent, just stir well. The specific formula is as follows:

[0028] E-51 bisphenol A epoxy resin: 100 grams

[0029] CPI-DAHTM powder: 15g

[0030] TGDDM epoxy resin: 100 grams

[0031] 4,4'-Diaminodiphenylsulfone: 15 grams

[0032] 2-Ethyl-4-methylimidazole: 5 grams

[0033] 1,3-Diglycidyloxybenzene: 30 grams.

Embodiment 3

[0035] Preparation process: Put bisphenol A epoxy resin and hydroxyl-containing carboxy-terminated imide (CPI-DAHTM) into a reaction bottle, stir and heat to 110°C, react to a homogeneous and transparent state, cool to 60°C, add N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane (TGDDM), reactive diluent and curing agent, just stir well. The specific formula is as follows:

[0036] E-44 bisphenol A epoxy resin: 50 grams

[0037] CPI-DAHTM powder: 1 g

[0038] TGDDM epoxy resin: 100 grams

[0039] Methyltetrahydrophthalic anhydride: 10 grams

[0040] 2-Ethyl-4-methylimidazole: 3 grams

[0041] Dicyandiamide: 7 grams

[0042] 2,2-bis(4-glycidyloxycyclohexyl)propane: 5 grams

[0043] Vinylcyclohexene dioxide: 15 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com