Two-stage enzyme treatment method for improving stalk shred smoking quality

A technology of enzyme treatment and cut stems, applied in the field of tobacco processing, can solve the problems of limited degradation effect of cell wall substances, and achieve the effects of improving smoking quality, increasing content and reducing irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

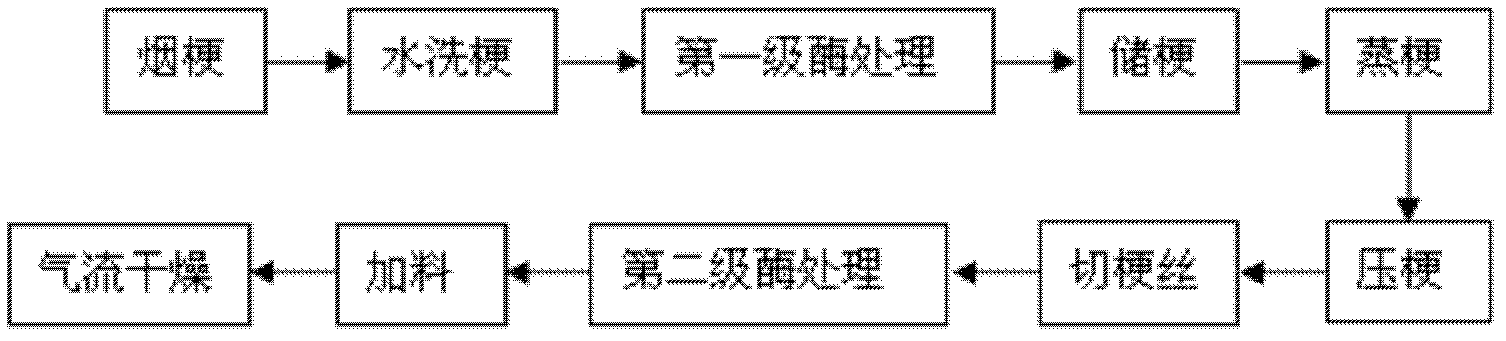

Method used

Image

Examples

Embodiment 1

[0024] Each component is dissolved in an appropriate amount of water according to the following weight percentages: 0.5% of pectinase, 0.5% of hemicellulase, 0.5% of cellulase and 0.5% of laccase. Filter and dilute the filtrate to the desired volume. The temperature of the compound enzyme solution is controlled at 45°C ± 5°C. The washed tobacco stems are immersed in the prepared compound enzyme solution for 10-20 seconds, taken out, and stored at 20-50° C. for 2 hours. Then steam the stems at 80°C to 100°C for 3 to 5 seconds.

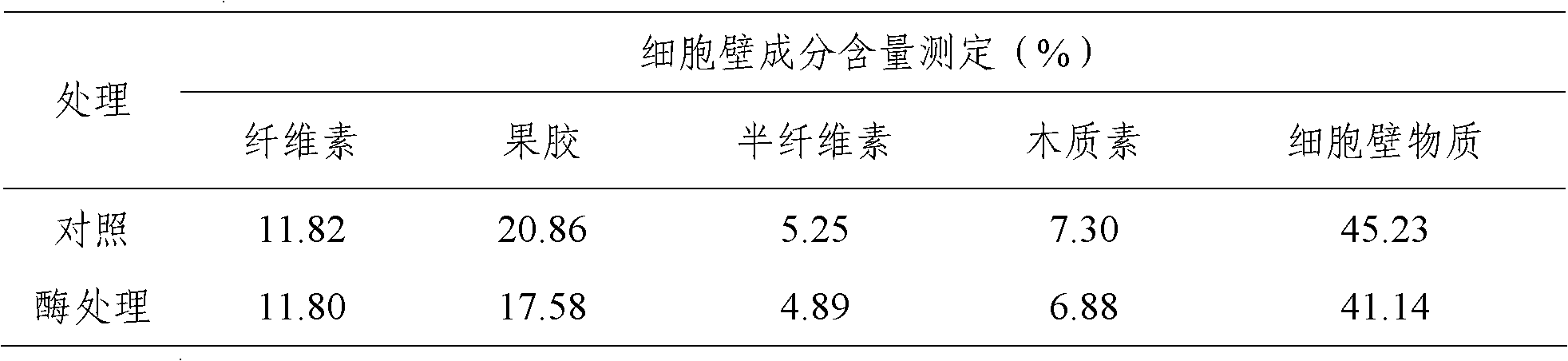

[0025] After compound enzyme treatment, tobacco stem cell wall substances, including pectin, cellulose, hemicellulose and lignin content, were all reduced; the chemical composition test results showed that the reducing sugar and total sugar content of tobacco stem increased after compound enzyme treatment , which is conducive to the improvement of the suction quality of cut stems.

[0026] Table 1 Cell wall substance content of tobacco stems after pr...

Embodiment 2

[0029] The difference from Example 1 is that the weight percentages of the components in the compound enzyme liquid are different, and the components are 1.0% pectinase, 0.3% hemicellulase, 0.3% cellulase and 0.5% laccase. Its technological process is identical with embodiment 1.

Embodiment 3

[0031] The tobacco stems processed by steaming the stems in Example 1 were cut into shreds after pressing the stems. Dissolve each component in an appropriate amount of water according to the weight percentage of the following enzymes and shredded stems: 0.2% pectinase, 0.2% hemicellulase, 0.2% cellulase, 0.2% laccase, 0.2% protease, 0.2% amylase , filter, and dilute the filtrate to the desired volume. Spray 50ml of enzyme solution per 1kg of shredded stems, spray the enzyme solution evenly on the shredded stems, and store for 2 hours. Air-dry the shredded stems at a temperature of 180°C.

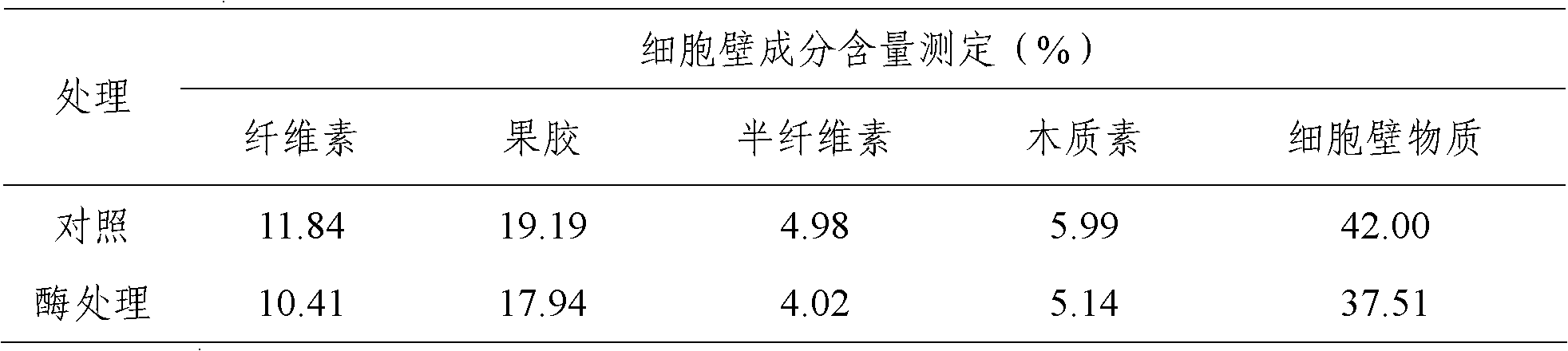

[0032] After the second-level compound enzyme treatment, the contents of the cut stem cell wall substances, including pectin, cellulose, hemicellulose and lignin, are all reduced, which can reduce the pungent odor produced when the cellulose and lignin are not fully burned. At the same time, bad odors such as woody gas produced by burning lignin and pectin can also be reduced.

[0033] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com