Multi-functional large-sized metal surface treating machine

A metal surface treatment machine technology, which is applied in metal processing equipment, used abrasive treatment devices, abrasive jetting machine tools, etc., can solve the problem of equipment size and maneuverability, the shot blasting head cannot be flexibly adjusted, and the impact Surface treatment efficiency and quality issues, to achieve the effect of reliable long-term automatic operation, excellent treatment quality, and improved mobility and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

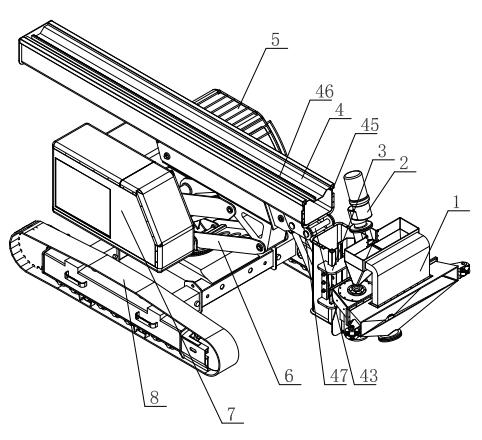

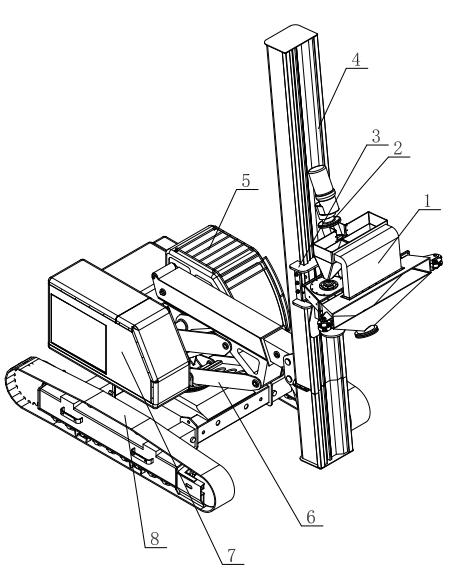

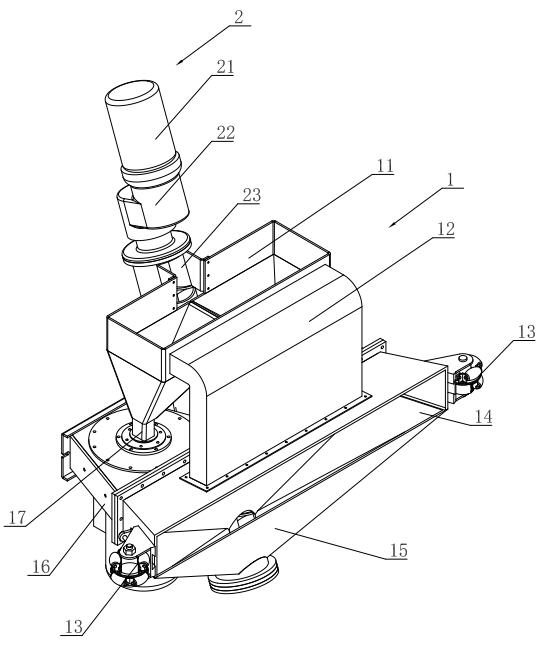

[0036] Such asfigure 1 , figure 2 As shown, the base 61 of the parallelogram linkage mechanism 6 of the support arm structure of the present invention is installed on the mobile platform 8 through a rotary pair, and a dust removal box 5 and a control room 7 are arranged on both sides of the parallelogram linkage mechanism 6; The guide rail 4 is arranged above the parallelogram linkage mechanism 6 , and the shot blasting head 1 and the working head parts of the shot feeding device 2 are slidably arranged on the guide rail 4 through the slider 3 . Such as figure 1 and figure 2 As shown, the mobile platform 8 of the present invention adopts a crawler structure. Of course, a fixed platform or a rail-type sliding platform can also be used to arrange the present invention on the production line. The parallelogram link mechanism 6 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com