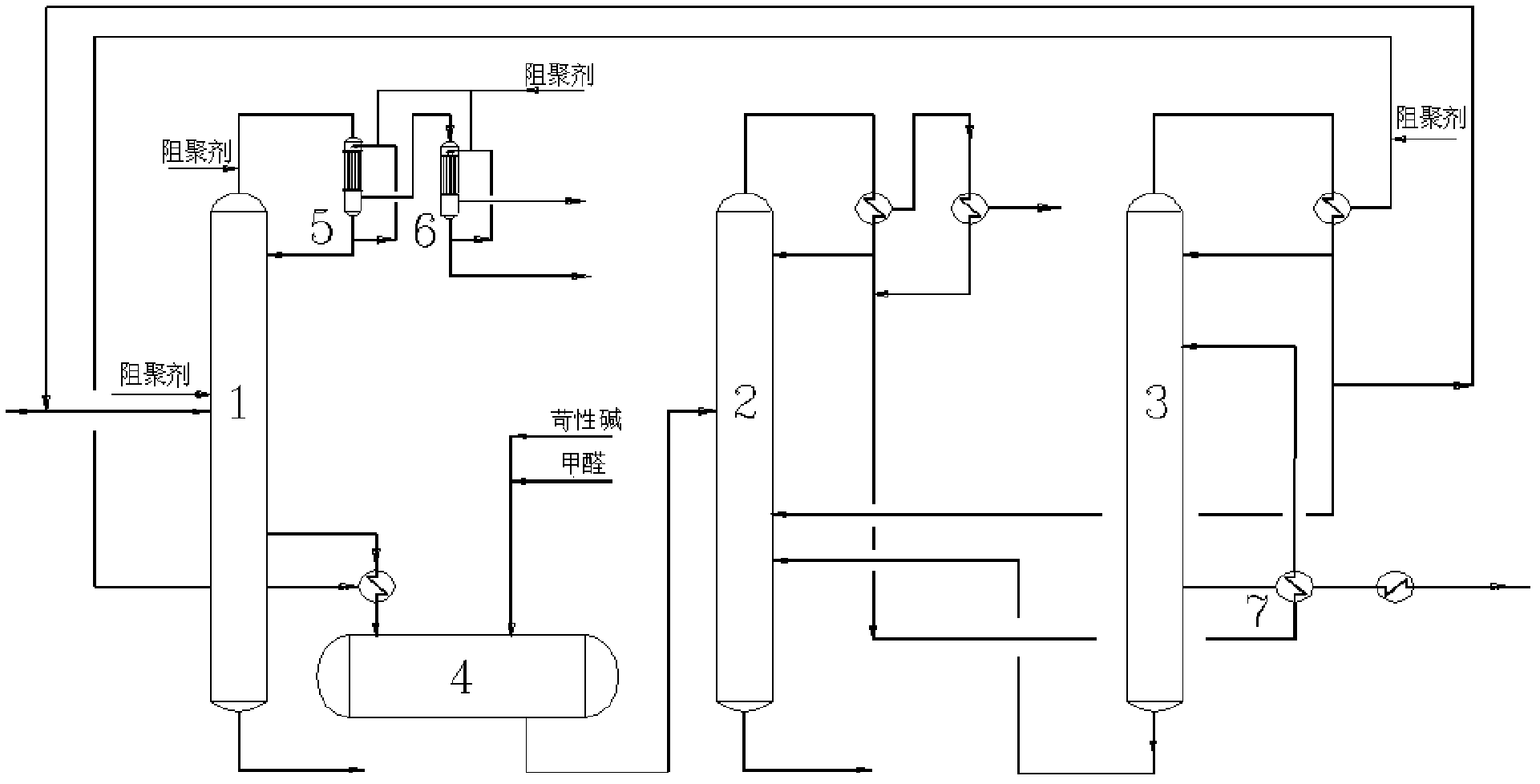

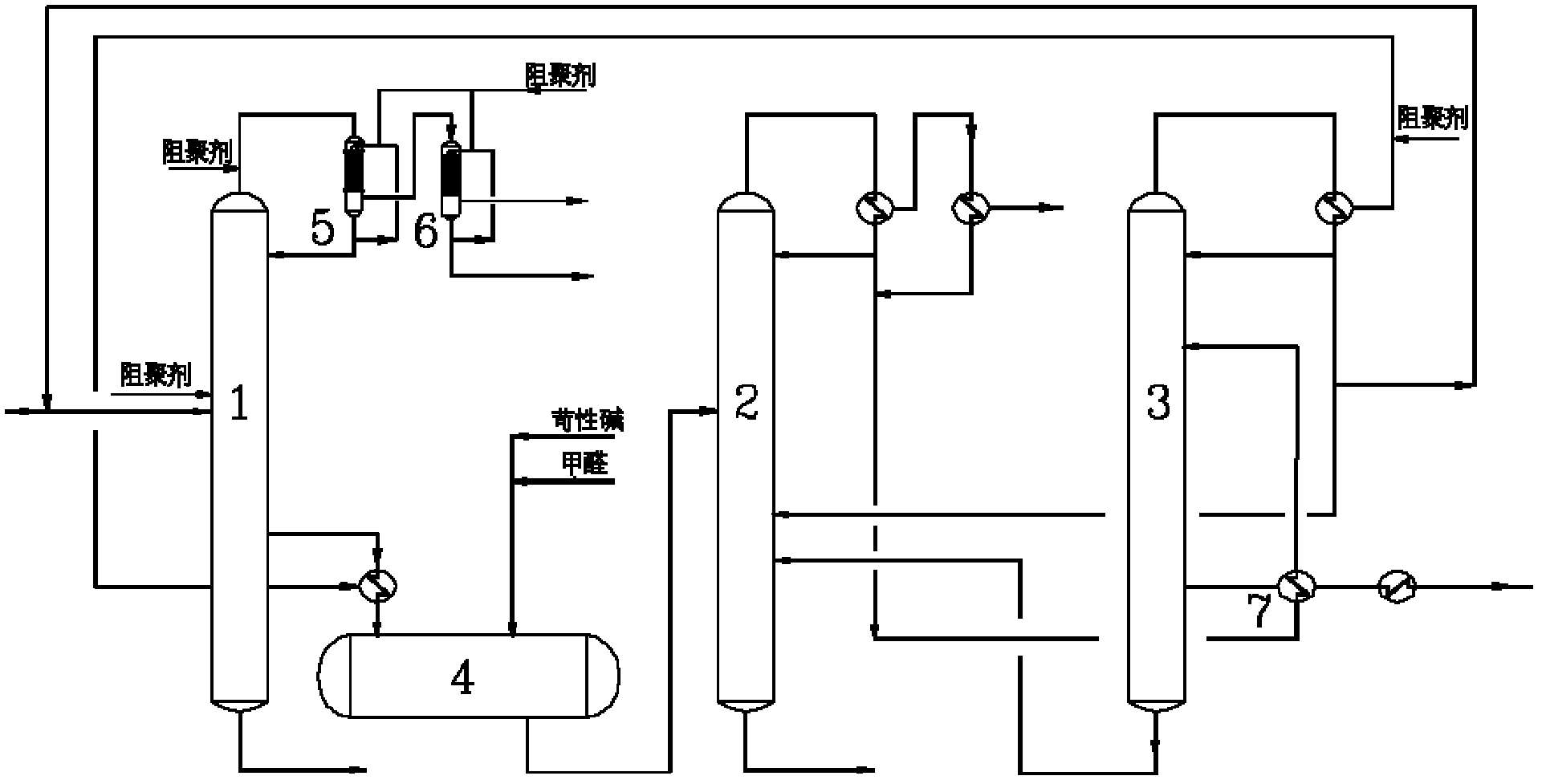

Continuous purification method for crude acetonitrile

A purification method and crude acetonitrile technology, applied in the direction of carboxylic acid nitrile purification/separation, organic chemistry, etc., can solve the problems of poor product purity and low energy utilization rate of the device, and achieve the effect of reducing operation burden, saving energy and ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Crude acetonitrile containing 50% acetonitrile, 45.95% water, 1.2% hydrocyanic acid, 2.4% acrylonitrile, 0.4% oxazole and 0.05% propionitrile is sent to the first rectification column.

[0044] The first rectification column adopts 23 theoretical plates, and crude acetonitrile enters the first rectification column from the fifth theoretical plate at first. The operating temperature at the top of the tower is 75°C, the operating temperature at the bottom of the tower is 100°C, the operating pressure at the top of the tower is 0.005MPa, the operating pressure at the bottom of the tower is 0.026MPa, and the reflux ratio is 13. The azeotrope of acetonitrile-water is extracted from the side line of the 15th theoretical plate, and sent to the acetonitrile reactor after condensation, and sodium hydroxide solution and formaldehyde are added at the same time to make the residual hydrocyanic acid and acrylonitrile in the azeotrope of acetonitrile-water After converting to high bo...

Embodiment 2

[0050] Crude acetonitrile containing 50% acetonitrile, 45.95% water, 1.2% hydrocyanic acid, 2.4% acrylonitrile, 0.4% oxazole and 0.05% propionitrile is sent to the first rectification column.

[0051] The first rectification column adopts 30 theoretical plates, and the crude acetonitrile enters the first rectification column from the 10th theoretical plate at first. The operating temperature at the top of the tower is 73°C, the operating temperature at the bottom of the tower is 97°C, the operating pressure at the top of the tower is 0.002MPa, the operating pressure at the bottom of the tower is 0.027MPa, and the reflux ratio is 20. The azeotrope of acetonitrile-water is extracted from the side line of the 20th theoretical plate, and sent to the acetonitrile reactor after condensation, and sodium hydroxide solution and formaldehyde are added at the same time to make the residual hydrocyanic acid and acrylonitrile in the azeotrope of acetonitrile-water After converting to high ...

Embodiment 3

[0057] Crude acetonitrile containing 50% acetonitrile, 45.95% water, 1.2% hydrocyanic acid, 2.4% acrylonitrile, 0.4% oxazole and 0.05% propionitrile is sent to the first rectification column.

[0058] The first rectification column adopts 40 theoretical plates, and the crude acetonitrile first enters the first rectification column from the sixth theoretical plate. The operating temperature at the top of the tower is 80°C, the operating temperature at the bottom of the tower is 104°C, the operating pressure at the top of the tower is 0.009MPa, the operating pressure at the bottom of the tower is 0.035MPa, and the reflux ratio is 12. The azeotrope of acetonitrile-water is extracted from the side line of the 25th theoretical plate, and sent to the acetonitrile reactor after condensation, and potassium hydroxide solution and formaldehyde are added at the same time to make the residual hydrocyanic acid and acrylonitrile in the azeotrope of acetonitrile-water After converting to hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com