Method for preparing high-quality LMW (low molecular weight) heparins

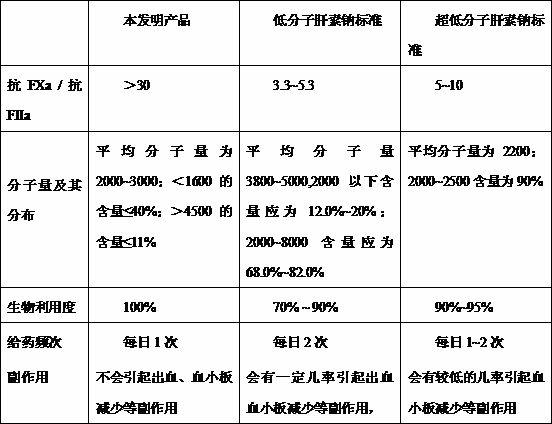

A molecular weight, high-quality technology, applied in the field of biomedicine, can solve the problems of harsh reaction conditions of ultra-low molecular weight heparin, low anti-FXa factor titer, and high anti-FIIa titer, achieving no thrombocytopenia and no bleeding. , The effect of low anti-FIIa titer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Weigh 1 kg of heparin sodium and 2.5 kg of benzethonium chloride salt for later use.

[0022] 1. Gradually add the weighed heparin sodium into 9 liters of distilled water until it is completely dissolved.

[0023] 2. Synthesis of heparin benzethonium chloride salt: 2.5 kg benzethonium chloride salt was added into distilled water and stirred until completely dissolved. Then add the benzethonium chloride salt solution slowly into the heparin sodium solution under stirring, continue to stir for 2 hours, then stop stirring, and let stand for a period of time. The supernatant was removed, and the remaining pellet suspension was centrifuged to collect the pellet.

[0024] 3. Pretreatment of heparin benzethonium chloride salt: add 10 L of distilled water to the precipitate obtained by centrifugation, stir, and soak for not less than 1 hour. Centrifuge at high speed, spread the sediment obtained from the final centrifugation evenly on stainless steel plates, the th...

Embodiment 2

[0038] Example 2: The difference between this example and Example 1 is that heparin sodium is 6 kg, benzethonium chloride is 15 kg, and benzyl chloride is 20 L.

[0039] Product testing results: average molecular weight is 2200 Da, molecular weight distribution: 20% of 4500 Da; anti-FXa titer: 162 IU / mg, anti-FIIa titer: 3.0 IU / mg , anti-FXa / anti-FIIa=54.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com