Synthetic method of aliphatic-series sulfonate high-efficiency water reducer

An aliphatic sulfonate and high-efficiency water-reducing agent technology, applied in the field of polymer synthesis, can solve the problem that the research work on the step-by-step synthesis of aliphatic sulfonate high-efficiency water-reducing agent is not carried out. Conveying, good water reduction enhancement effect, good setting retardation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of the 1# aliphatic sulfonate superplasticizer of this embodiment:

[0019] (1) Preparation of acetone-formaldehyde condensate macromolecules: prepare a mixed solution of formaldehyde: acetone molar ratio 1:1, react for 60min under the conditions of pressure 0.6MPa, temperature 45℃, stirring speed 85r / min, after the condensation reaction is complete , to make acetone-formaldehyde condensation liquid;

[0020] (2) Synthesis reaction of water reducing agent: formaldehyde: acetone-formaldehyde condensation liquid: sodium sulfite according to the molar ratio of 1:1:0.35 (anhydrous sodium sulfite is used as catalyst and sulfonating agent), at a pressure of 0.6MPa and a temperature of 80°C After reacting for 2.5 hours at a stirring rate of 100r / min, dry and distill to obtain a light brown viscous liquid with a water content of 40wt%, which is the 1# aliphatic sulfonate superplasticizer.

Embodiment 2

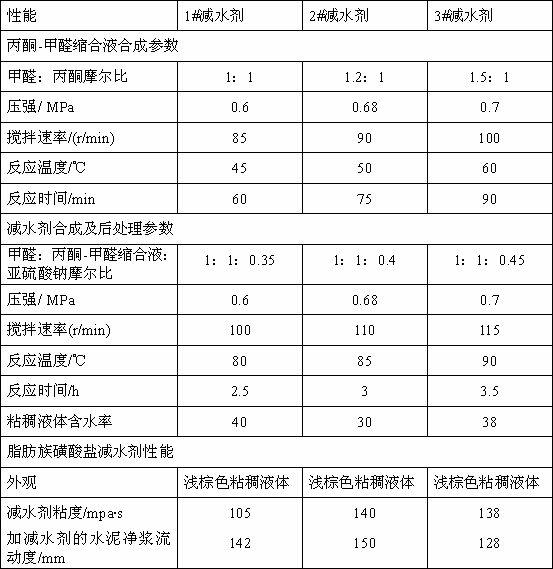

[0022] The preparation method of the 2# aliphatic sulfonate superplasticizer of this example is the same as that of Example 1, and the specific experimental parameters are shown in Table 1.

Embodiment 3

[0024] The preparation method of the 3# aliphatic sulfonate superplasticizer of this example is the same as that of Example 1, and the specific experimental parameters are shown in Table 1.

[0025]

[0026] Table 1 Experimental parameters of Examples 1 to 3 and performance of the obtained water reducer

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com