Method for co-production of urea and methanol by treating high-concentration ammonia nitrogen and 1, 5-cyclooctadiene (COD) sewage

A sewage treatment, high-concentration technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of no secondary pollution and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

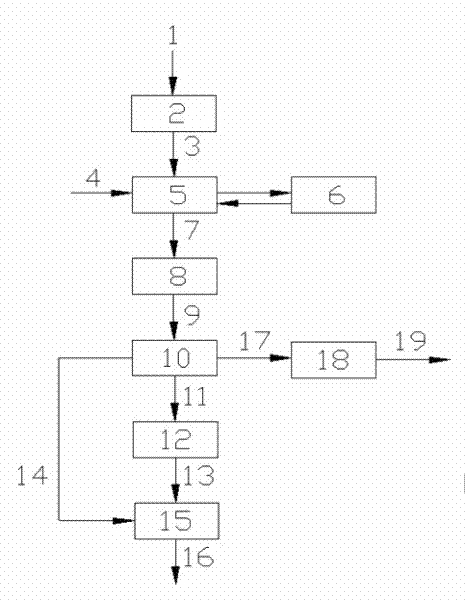

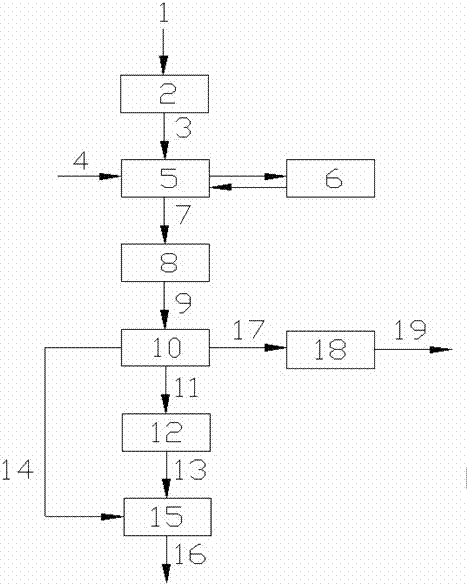

[0013] The present invention will be described in detail below with regard to specific embodiments in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, high-concentration ammonia nitrogen, COD sewage, fine coal, and coal slurry additive 1 are added to the coal slurry preparation device 2, and mixed in a coal mill to make a weakly alkaline multi-component coal slurry 3 with a concentration of 55-70%; The multi-component coal slurry and oxygen 4 with a purity greater than 98% are sent to the coal slurry gasification device 5, mixed and atomized in the burner, and then enter the coal slurry gasifier. Conversion and oxidation reaction to generate water gas; conversion of ammonia nitrogen and COD to generate CO and CO 2 、H 2 , N 2 , the water gas is washed by washing water to cool down and remove dust; the washing water is a closed-circuit full-cycle washing water, and the water after the gas washing is sent to the washing water treatment device 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com