Quartz fiber reinforced concrete quartz microwave-absorbing ceramic stuffed with silicon carbide micro-powder and preparation method thereof

The technology of silicon carbide micropowder and quartz fiber is applied in the field of quartz fiber reinforced quartz wave absorbing ceramics and its preparation, which can solve the problems of low dielectric constant and dielectric loss, difficult wave absorption function, etc. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

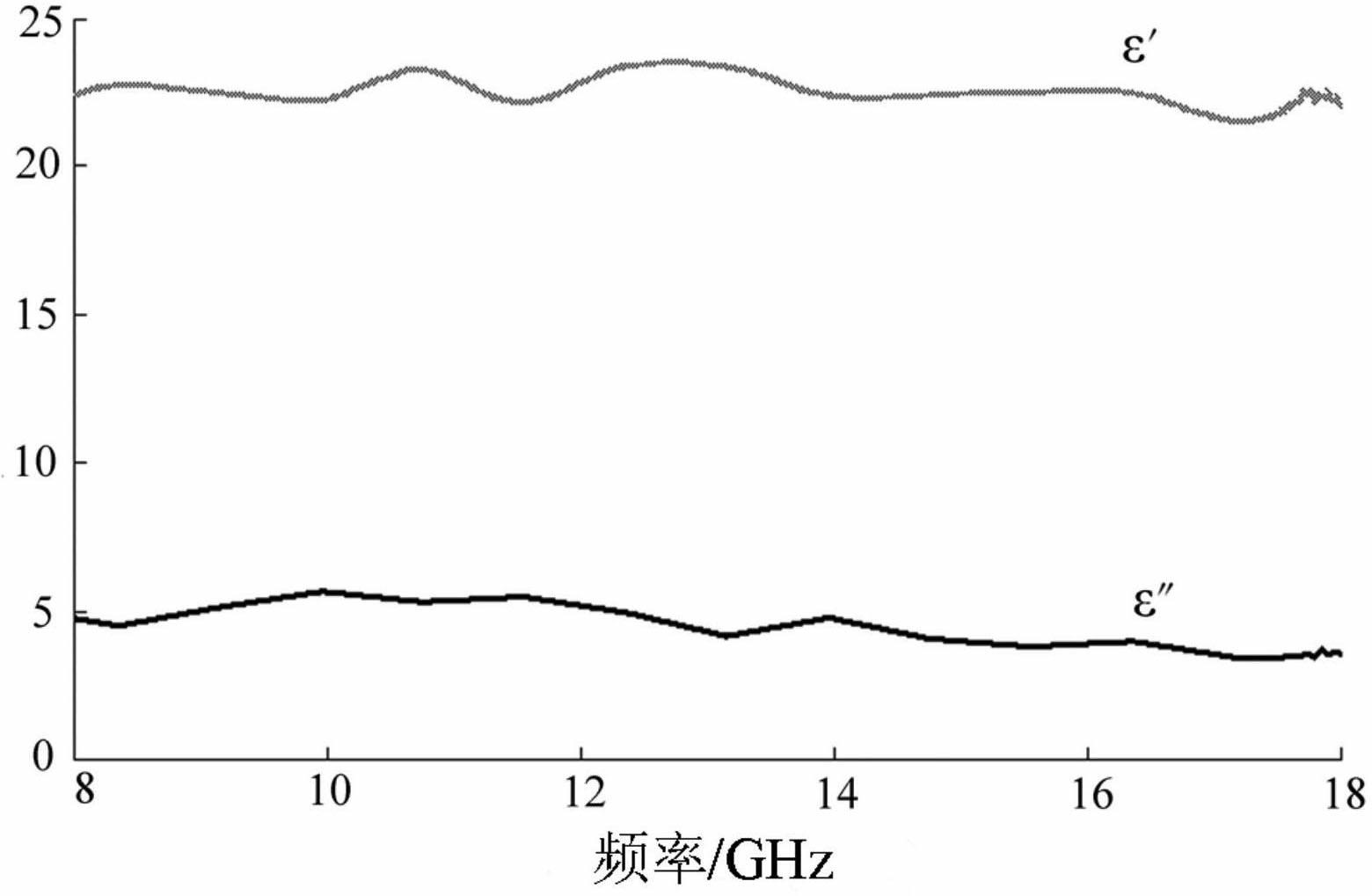

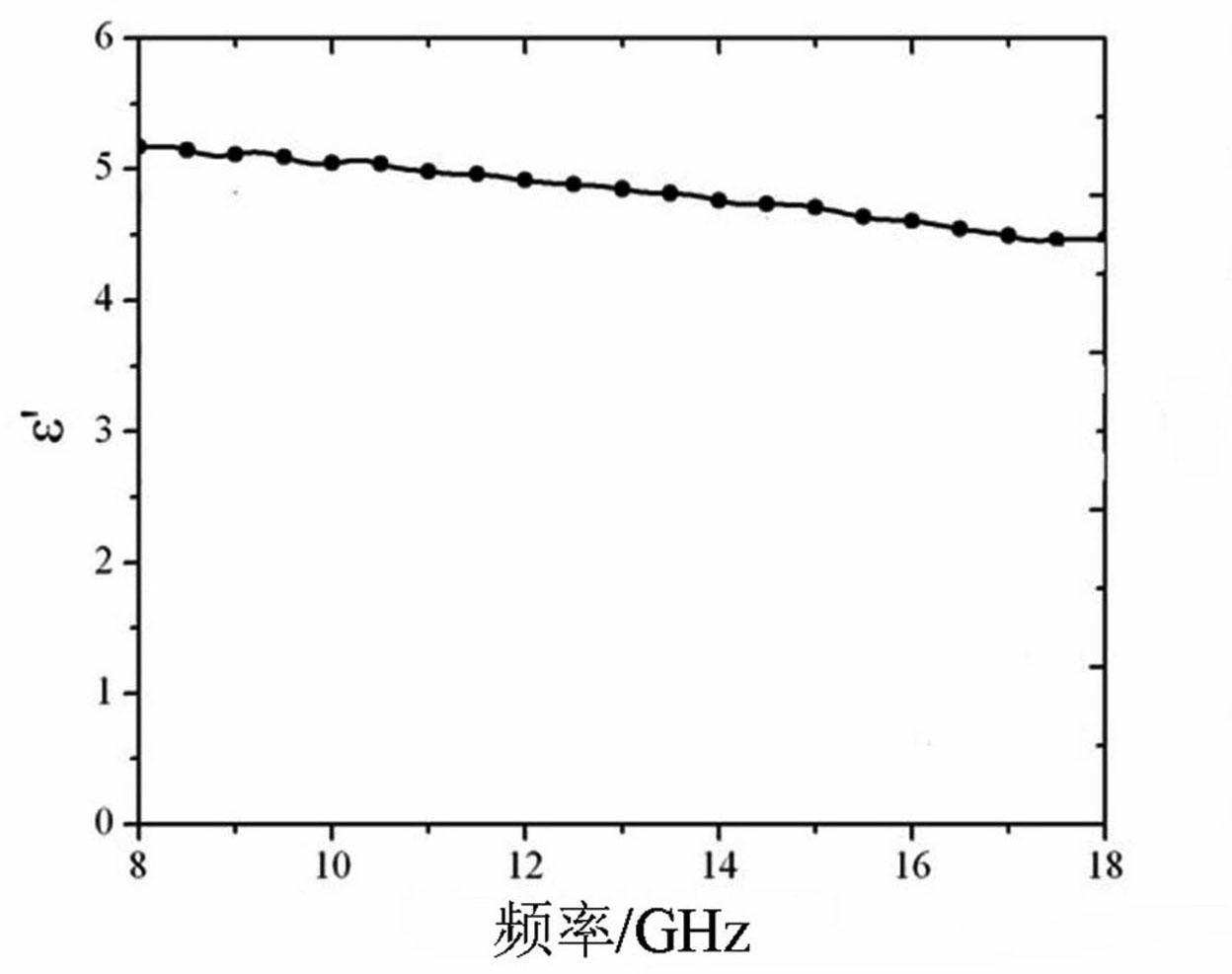

[0034] A quartz fiber-reinforced quartz wave-absorbing ceramic filled with silicon carbide micro-powder according to the present invention, the wave-absorbing ceramic uses silicon dioxide as a matrix, quartz fiber as a reinforcing phase, and silicon carbide micro-powder as a filler, and the silicon carbide micro-powder is α- SiC, purity > 99.9%, the average particle size of silicon carbide powder is 0.5 μm; the volume fraction of the reinforcing phase (preform made of quartz fibers) is 44.7vol.%, and the mass ratio of matrix to silicon carbide powder is 3.6:1.

[0035] The preparation method of the silica fiber-reinforced quartz wave-absorbing ceramics of the silicon carbide micropowder filler of the present embodiment comprises the following steps:

[0036] (1) Material preparation: prepare silica sol, the sol particle size of silica sol is 29nm, the solid content is 32.7%, and the pH value is 3; prepare the puncture stitched woven piece of quartz fiber cloth, the fiber volume...

Embodiment 2

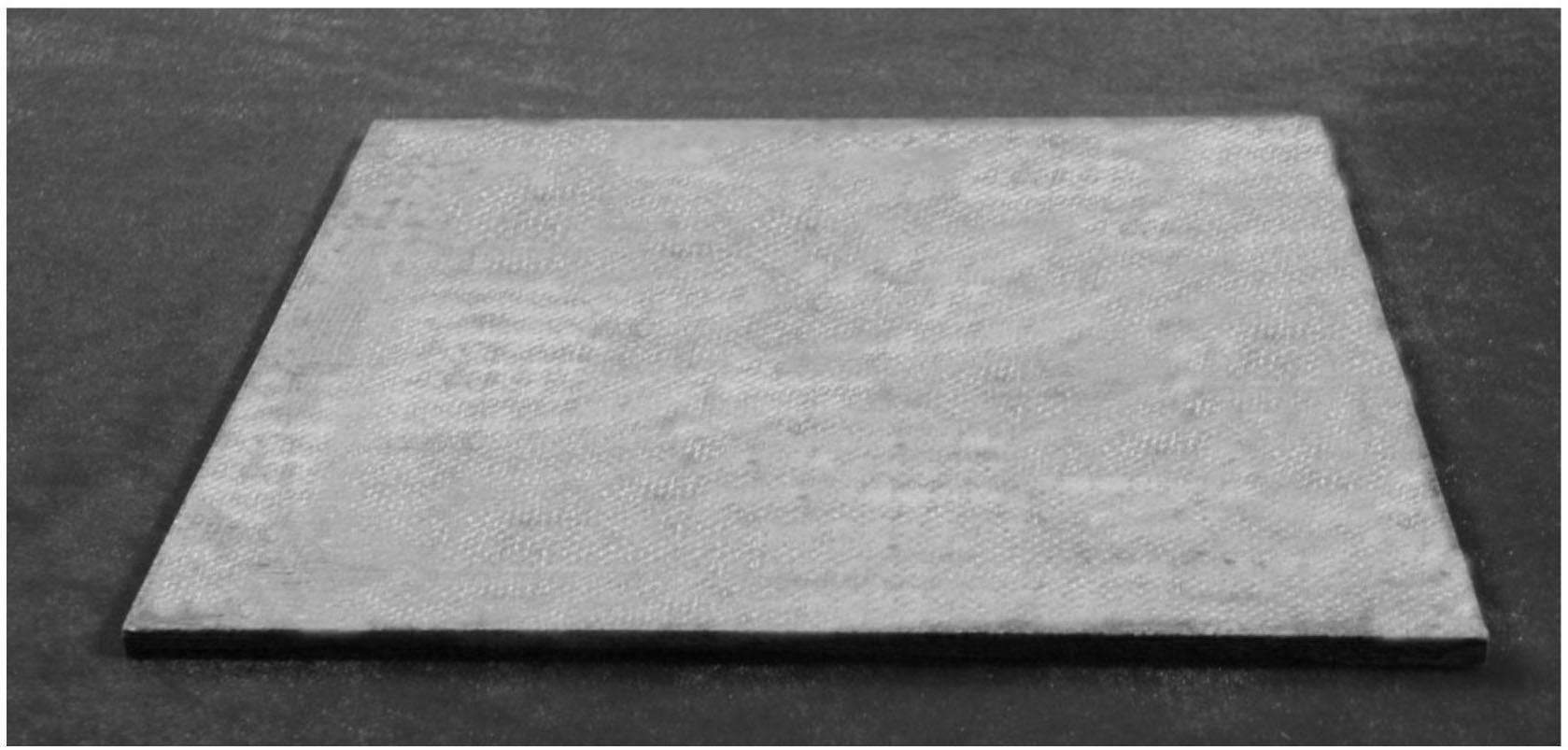

[0044] a kind of like figure 2 The silica fiber-reinforced quartz wave-absorbing ceramics of the present invention shown as silicon carbide powder fillers, the wave-absorbing ceramics use silicon dioxide as a matrix, quartz fibers as a reinforcing phase, silicon carbide powder as a filler, and silicon carbide powder as α -SiC, purity > 99.9%, the average particle size of silicon carbide powder is 0.4 μm; the volume fraction of the reinforcement phase (preform made of quartz fibers) is 45.2vol.%, and the mass ratio of matrix to silicon carbide powder is 1.6:1 .

[0045] The preparation method of the silica fiber-reinforced quartz wave-absorbing ceramics of the silicon carbide micropowder filler of the present embodiment comprises the following steps:

[0046] (1) Material preparation: prepare silica sol, the particle size of silica sol is 26nm, the solid content is 32.7%, and the pH value is 6; prepare the puncture-sewn woven piece of quartz fiber cloth, the fiber volume frac...

Embodiment 3

[0054] A quartz fiber-reinforced quartz wave-absorbing ceramic filled with silicon carbide micro-powder according to the present invention, the wave-absorbing ceramic uses silicon dioxide as a matrix, quartz fiber as a reinforcing phase, and silicon carbide micro-powder as a filler, and the silicon carbide micro-powder is α- SiC, purity > 99.9%, the average particle size of silicon carbide powder is 0.2 μm; the volume fraction of the reinforcement phase (preform made of quartz fibers) is 42.9vol.%, and the mass ratio of matrix to silicon carbide powder is 3 / 5.

[0055] The preparation method of the silica fiber-reinforced quartz wave-absorbing ceramics of the silicon carbide micropowder filler of the present embodiment comprises the following steps:

[0056] (1) Material preparation: prepare silica sol, the sol particle size of silica sol is 32nm, the solid content is 32.7%, and the pH value is 5; prepare the puncture stitched woven piece of quartz fiber cloth, the fiber volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com