Polarization modified biological carrier and preparation method thereof

A biological carrier and modified technology, applied in the direction of being fixed on or in an inorganic carrier, immobilized on or in an organic carrier, etc., can solve the problem of low efficiency of organic matter treatment, slow growth of microorganisms, and large energy consumption of circulating backflow, etc. problems, to achieve the effect of reducing sludge treatment costs, long life cycle, and improving shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

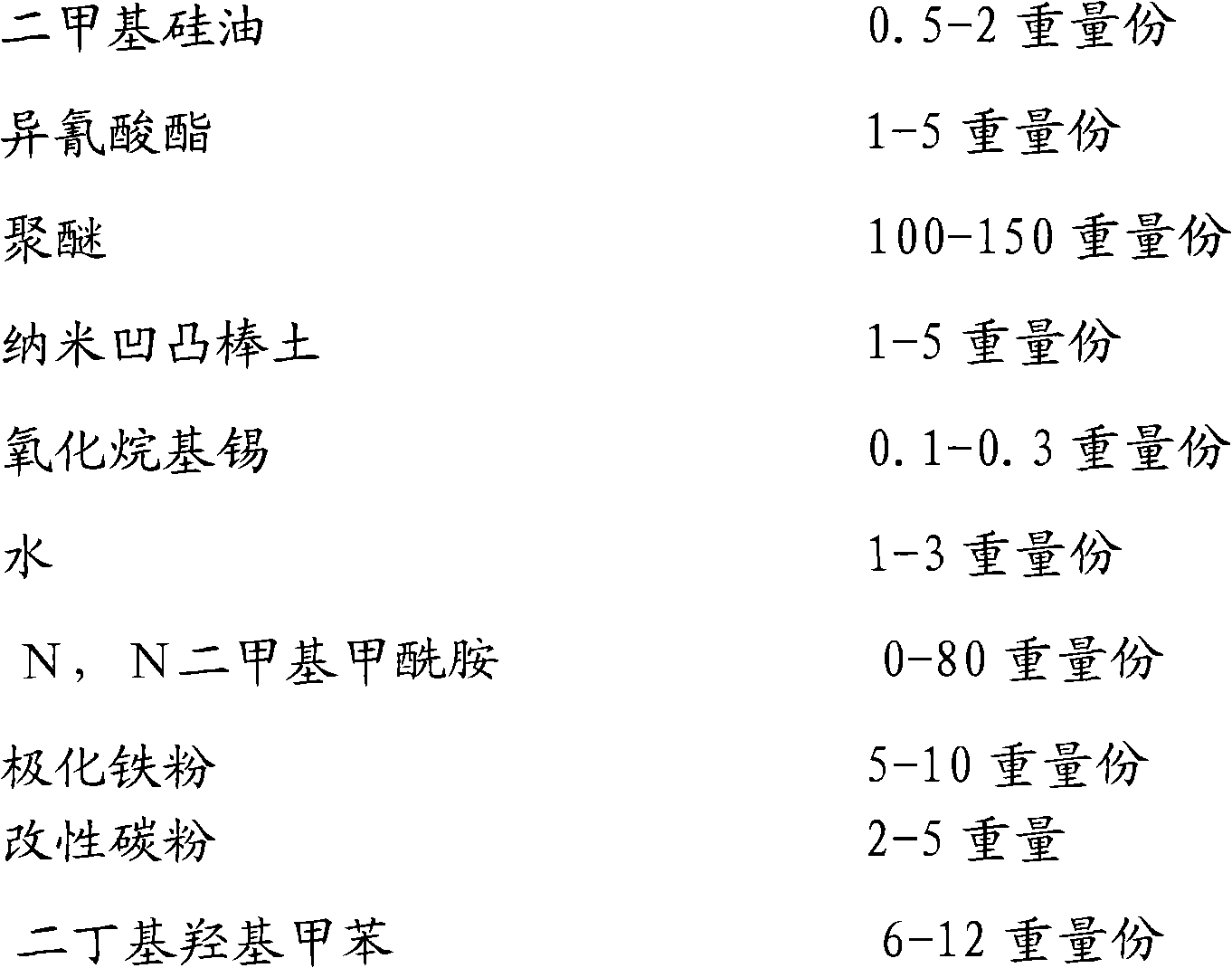

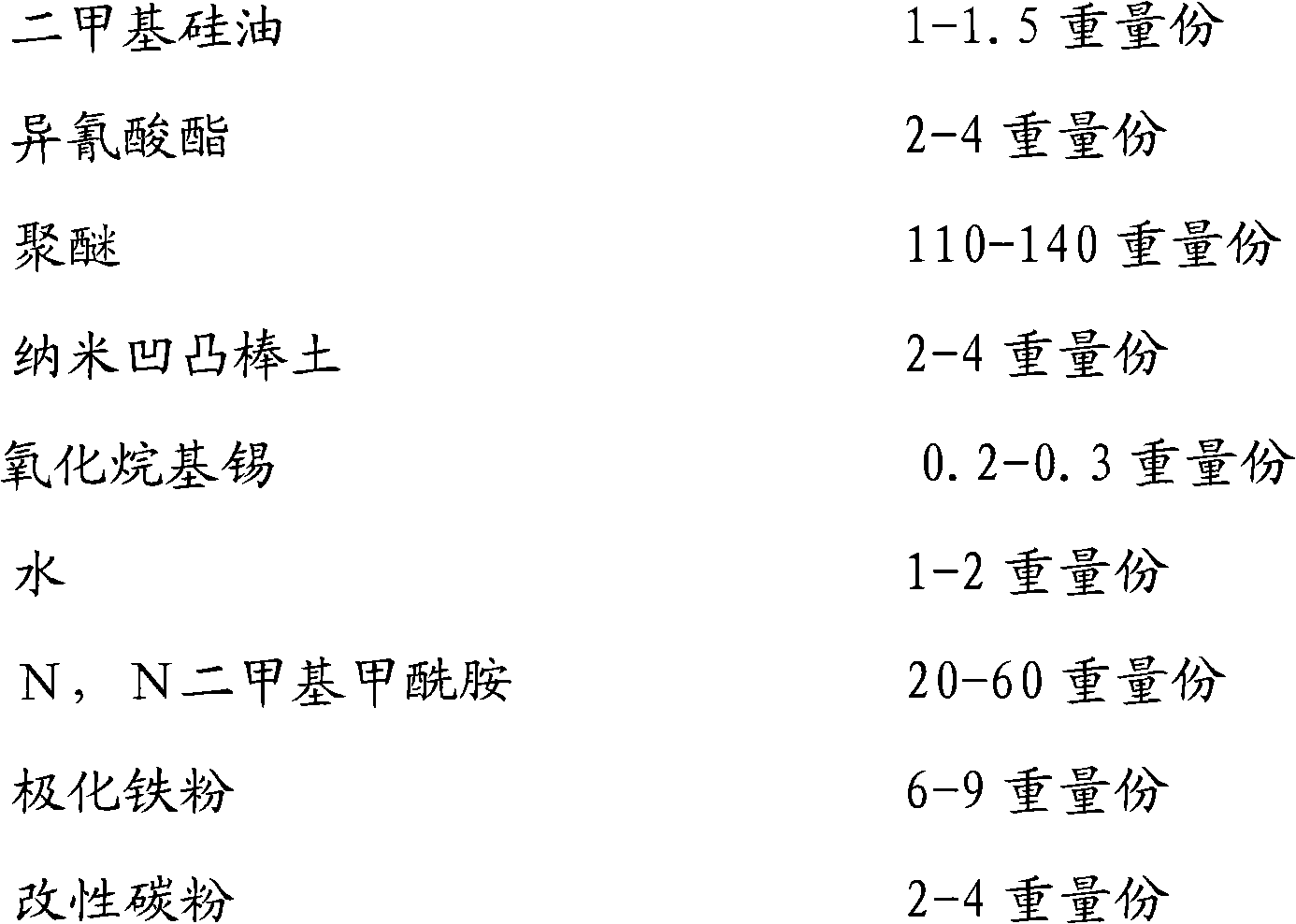

[0030] A. Mix 120 parts by weight of polyether, 0.3 parts by weight of alkyl tin oxide, and 60 parts by weight of N,N dimethylformamide in proportion. At about 25°C, add 4 parts by weight of isocyanate, add water and stir, and enter foaming stage, add 3 parts by weight of nano-attapulgite to make the water treatment filler have good hydrophilicity;

[0031] B. Stir for 15 minutes, add 1.5 parts by weight of dimethyl silicone oil for defoaming. At this stage, 8 parts by weight of polarized iron powder and 4 parts by weight of modified carbon powder are added to change the internal molecular bonds of the material and enhance the yin and yang of the redox reaction Pole, internally produces compounds with strong adsorption capacity;

[0032] C. After reacting at 25°C for 3 hours, the material is in the coagulation process, and 10 parts by weight of dibutyl hydroxytoluene compound is added to improve the stability and surface activity of the material;

[0033] D. Cut into blocks a...

Embodiment 2

[0035] A. Mix 110 parts by weight of polyether, 0.2 parts by weight of alkyl tin oxide, and 40 parts by weight of N,N dimethylformamide in proportion, and then add 3 parts by weight of isocyanate at about 25°C, add water and stir, and enter foaming stage, add 2 parts by weight of nano-attapulgite to make the water treatment filler have good hydrophilicity;

[0036] B. Stir for 15 minutes, add 1 weight part of dimethyl silicone oil for defoaming. At this stage, 6 weight parts of polarized iron powder and 3 weight parts of modified carbon powder are added to change the internal molecular bonds of the material and enhance the yin and yang of the redox reaction Pole, internally produces compounds with strong adsorption capacity;

[0037] C. After reacting at 25°C for 3 hours, the material is in the coagulation process, and 8 parts by weight of dibutyl hydroxytoluene compound are added to improve the stability and surface activity of the material;

[0038] D. Cut into blocks after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com