Production method for superfine tungsten carbide powder

A production method, tungsten carbide technology, applied in the production field of ultra-fine tungsten carbide powder, can solve the problems of high free carbon and high total carbon content, achieve narrow particle size distribution, reduce production cost, and have good dispersion and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

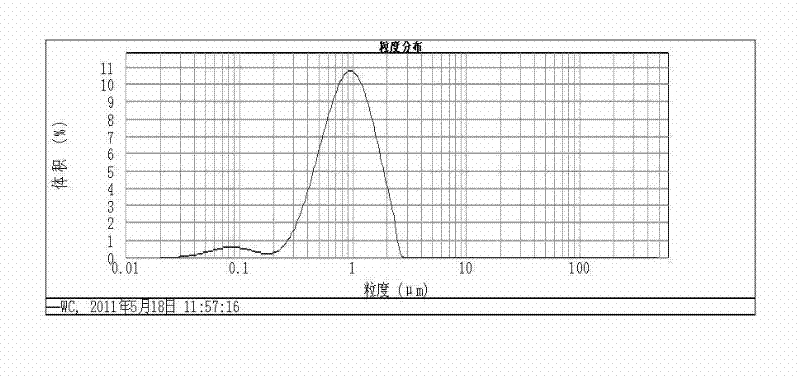

[0017] Example 1 The mass percentage of the carbon content of the precursor powder is 14.5%, and the balance is violet tungsten WO x , x is 2.60; add chromium trioxide with 1% mass percentage of precursor powder. The above-mentioned powder uses alcohol as the ball milling medium, the liquid-solid ratio is 400ml / kg, and the ball milling time is 24 hours. The ball-milled powder is dried in an oven at 80-95°C for 3 hours. The dried powder is put into a graphite boat and carbonized once in a non-oxidizing atmosphere. The carbonization temperature is 1000-1100°C and the carbonization time is 1 hour. The carbonized product was ball milled and mixed for 3 hours, and the total carbon content was detected to be 5.96%. Adjust the amount of carbon to 6.15%, and then ball mill and mix for 6 hours, then put it into a graphite boat, and put it in the H 2 Carry out secondary carbonization in the middle, the secondary carbonization temperature is 1200 ~ 1300 ℃, and the carbonization time is...

Embodiment 2

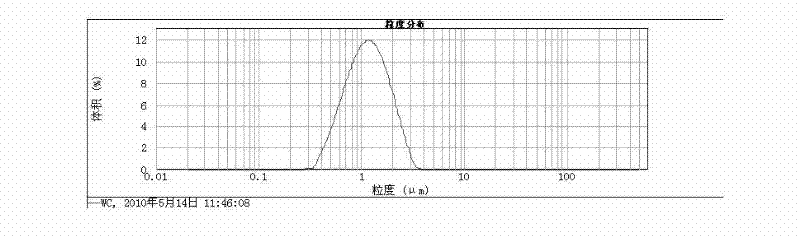

[0018] Example 2 The mass percentage of the carbon content of the precursor powder is 14.0%, and the balance is violet tungsten WO x , x is 2.65; add 0.7% chromium trioxide of precursor powder mass percentage. The above-mentioned powder uses alcohol as the ball milling medium, the liquid-solid ratio is 400ml / kg, and the ball milling time is 18 hours. The ball-milled powder is dried in an oven at 80-95°C for 3 hours. The dried powder is put into a graphite boat and carbonized once in a non-oxidizing atmosphere. The carbonization temperature is 1000-1100°C and the carbonization time is 2 hours. The carbonized product was ball milled and mixed for 2 hours, and the total carbon content was detected and analyzed to be 5.43%. Adjust the amount of carbon to 6.25%, and then mix for 4 hours, and put the carbonized product of the adjusted carbon into the graphite boat. 2 Carry out secondary carbonization in the middle, carbonization temperature 1200 ~ 1300 ℃, carbonization 2 hours. T...

Embodiment 3

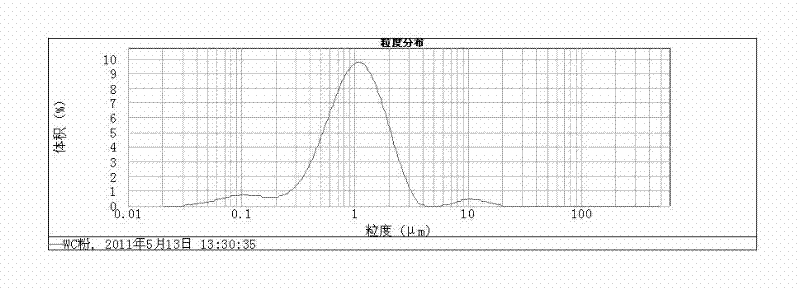

[0019] Example 3 The mass percentage of the carbon content of the precursor powder is 13.4%, and the balance is violet tungsten WO x , x is 2.70; add 0.3% chromium trioxide of precursor powder mass percentage. The above powder is milled with alcohol as the ball milling medium, the liquid-solid ratio is 400ml / kg, and the ball milling time is 12 hours. The ball-milled powder is dried in an oven at 80-95°C for 3 hours, and the dried powder is put into a graphite boat for primary carbonization in a non-oxidizing atmosphere. The primary carbonization temperature is 1100-1250°C, and the carbonization time is 3 hours. The primary carbonized product was ball milled and mixed for 2 hours, and the total carbon content was detected to be 5.33%. Adjust the amount of carbon to 6.20%, and then ball mill and mix for 3 hours, put it into a graphite boat, and 2 Carry out secondary carbonization in the middle, the secondary carbonization temperature is 1300 ~ 1400 ℃, and the carbonization tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com