Multi-layer tunnel cascaded semiconductor laser

A laser and semiconductor technology, applied in the structure of optical waveguide semiconductor and the structure of active area, etc., can solve the problems of reduced light extraction efficiency and power, high tunnel junction resistance and voltage, large divergence angle, etc., to improve the output optical power. , the internal resistance and its pressure drop are reduced, and the effect of high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

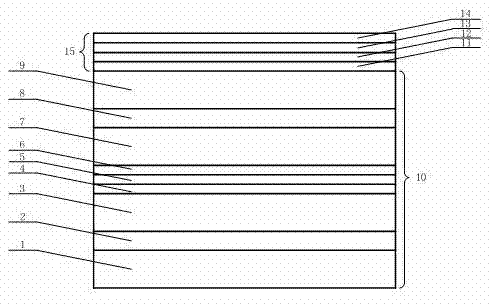

[0025] Depend on figure 1 It can be seen that the multi-layer tunnel cascaded semiconductor laser includes three vertically connected single-layer laser units 10 with the same structure; two adjacent single-layer laser units 10 pass through tunnel junctions with special structures according to semiconductor crystal growth rules. The unit 15 is grown and connected; the tunnel junction unit 15 includes a highly doped PN junction and a highly doped superlattice layer regularly grown on the upper and lower sides of the PN junction; the superlattice layer includes a semiconductor crystal The P-type superlattice layer 11 and the N-type superlattice layer 14 on the upper side of the P-type superlattice layer 14 that growth rule grows in the highly doped PN junction; N-type semiconductor layer 13 formed by doping technology.

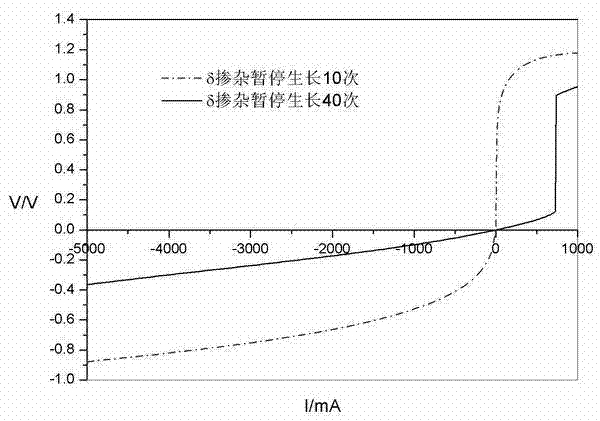

[0026] In this embodiment, 11-14 form a tunnel junction unit 15 with a special structure. The single-layer laser unit 10 is a 900nm semiconductor laser, and t...

Embodiment 2

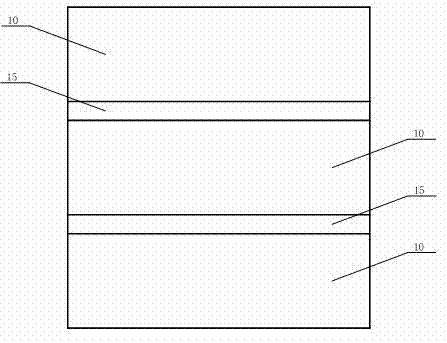

[0039] Depend on Figure 6 and Figure 7 As we know, the difference from Embodiment 1 is that this embodiment consists of two single-layer laser units 10—the first single-layer laser unit 16 and the second single-layer laser unit 18, and these two laser units pass through a tunnel with a special structure. The junction unit 15 is connected.

[0040] The structures of these two single-layer laser units 10 are different, the first single-layer laser unit 16 is a 940nm semiconductor laser, the second single-layer laser unit 18 is a 980nm semiconductor laser, and the level distribution of the second single-layer laser unit 18 is the same as in the embodiment The layer distribution of the single-layer laser unit 10 (900nm semiconductor laser) in 1 is the same, but the layer distribution of the first single-layer laser unit 16 is different from that of the single-layer laser unit 10 in Embodiment 1. The biggest difference is that the above The cladding layer and the lower cladding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com