Preparation method of high-dielectric-constant ceramics/polymer-based composite dielectric materials

A high dielectric constant and dielectric material technology, applied in the field of composite materials, can solve the problem of poor interface bonding, low dielectric constant of composite dielectric materials, poor mixing uniformity of copper calcium titanate ceramic powder and polyvinylidene fluoride, etc. problem, to achieve the effect of increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The present invention will be described in further detail below. The preparation method of high dielectric constant ceramic / polymer matrix composite dielectric material is characterized in that the steps of preparation are as follows:

[0014] 1. Filler pretreatment: add the silane coupling agent Si69 dropwise to the copper calcium titanate ceramic powder, the mass of the dropped silane coupling agent Si69 accounts for 5% to 10% of the mass of the copper calcium titanate ceramic powder, stir Evenly, then bake in an oven at 150°C for 5 minutes to 15 minutes;

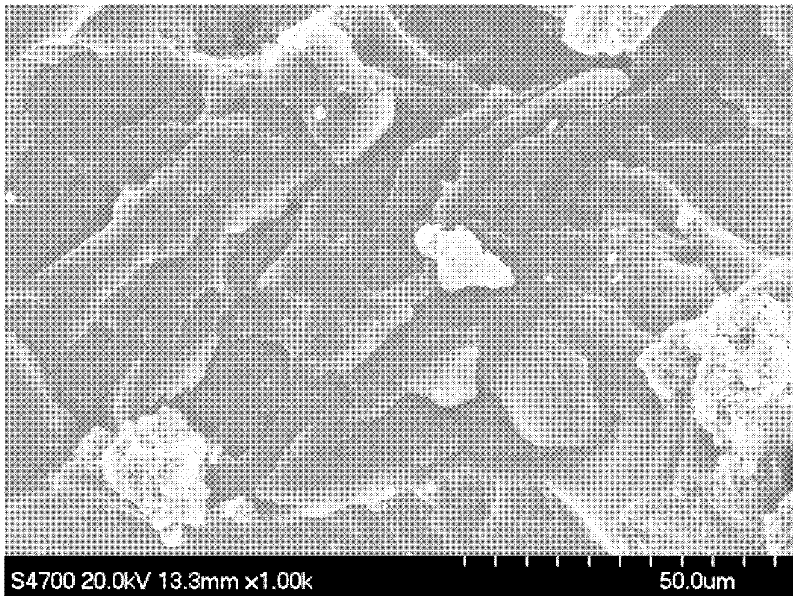

[0015] 2. Ingredients: Measure polyvinylidene fluoride and pretreated copper calcium titanate ceramic powder according to the proportion; the volume percentage of copper calcium titanate ceramic powder is 10% to 40%, and the particles of copper calcium titanate ceramic powder The size is 10μm~500μm, and the balance is polyvinylidene fluoride;

[0016] 3. Prepare the raw material mixture: put the measured copper c...

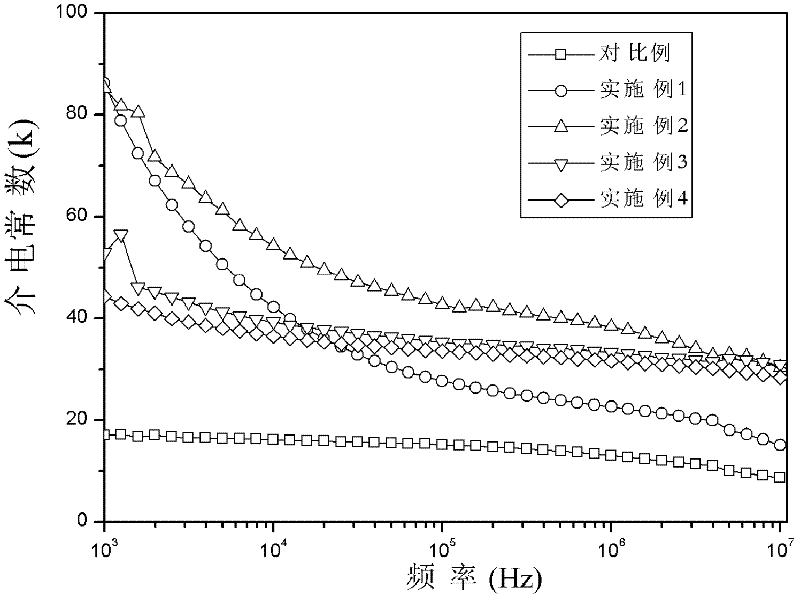

Embodiment 1

[0021] Add the silane coupling agent Si69 dropwise to the copper calcium titanate ceramic powder, the mass of the dropped silane coupling agent Si69 accounts for 5% of the mass of the copper calcium titanate ceramic powder, stir evenly, and then place it in an oven at 150°C Bake for 10 minutes; measure the polyvinylidene fluoride and the pretreated copper calcium titanate ceramic powder according to the volume ratio of 83:17, the volume percentage of the copper calcium titanate ceramic powder is 17%; the measured Copper calcium titanate ceramic powder and polyvinylidene fluoride are placed in a container, and N,N-dimethylformamide is poured into it. The volume ratio of polyvinylidene fluoride to N,N-dimethylformamide is 1:18, Stir in a magnetic stirrer for 1 hour to make a raw material mixture; coat the raw material mixture on a glass plate with a coating thickness of 0.2mm, remove it after natural drying to form a composite dielectric film; spread the composite dielectric film...

Embodiment 2

[0023] Add the silane coupling agent Si69 dropwise to the copper calcium titanate ceramic powder, the mass of the dropped silane coupling agent Si69 accounts for 10% of the mass of the copper calcium titanate ceramic powder, stir evenly, and then place it in an oven at 150°C Bake for 10 minutes; measure the polyvinylidene fluoride and the pretreated copper calcium titanate ceramic powder according to the volume ratio of 83:17, the volume percentage of the copper calcium titanate ceramic powder is 17%; the measured Copper calcium titanate ceramic powder and polyvinylidene fluoride are placed in a container, and N,N-dimethylformamide is poured into it. The volume ratio of polyvinylidene fluoride to N,N-dimethylformamide is 1:18, Stir in a magnetic stirrer for 1 hour to make a raw material mixture; coat the raw material mixture on a glass plate with a coating thickness of 0.2mm, remove it after natural drying to form a composite dielectric film; spread the composite dielectric fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com