Method for processing red sea bream collagen polypeptide-chromium (III) chelate

A fish collagen and collagen peptide technology, which is applied in the processing field of red sea bream collagen polypeptide-chromium chelate, can solve the problem of low utilization rate, insufficient nutritional value and function of fish skin and fish scale, and environmental pollution. and other problems, to achieve the effect of low cost, lower activation energy, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

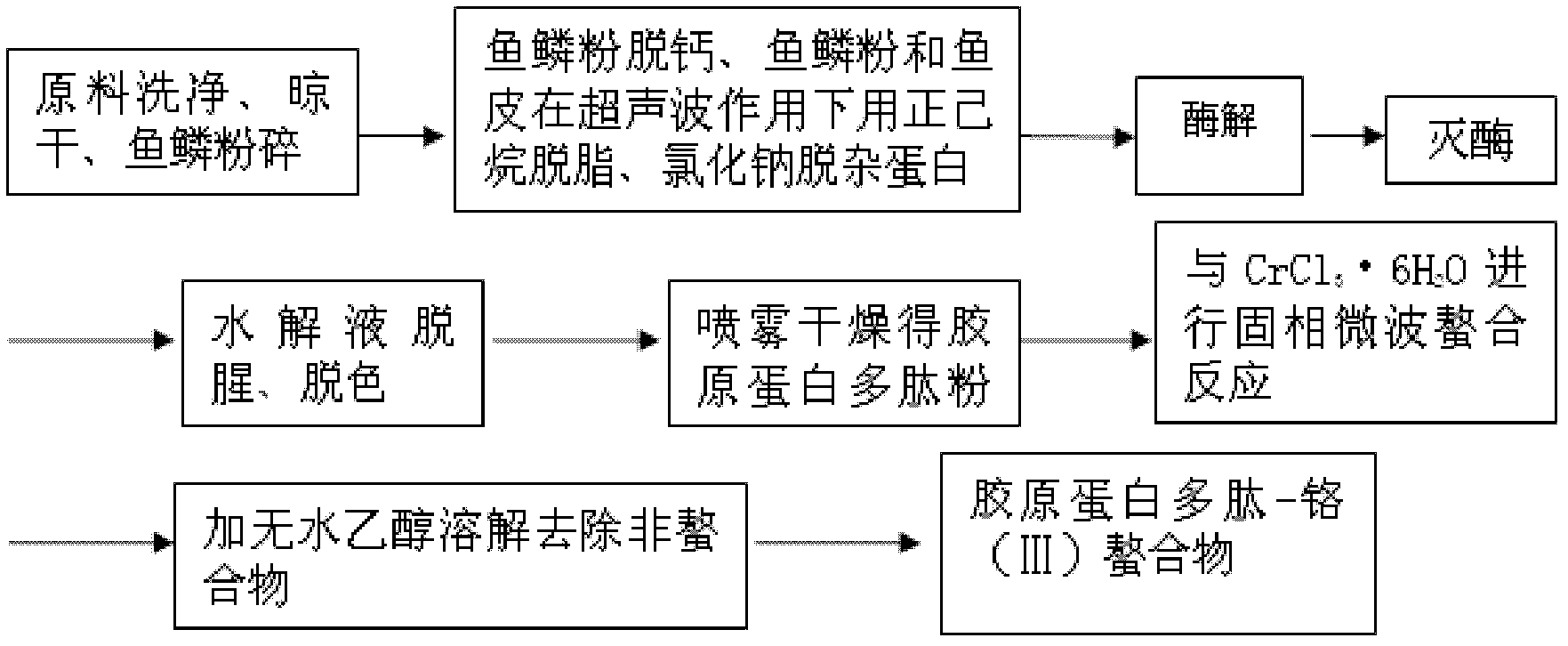

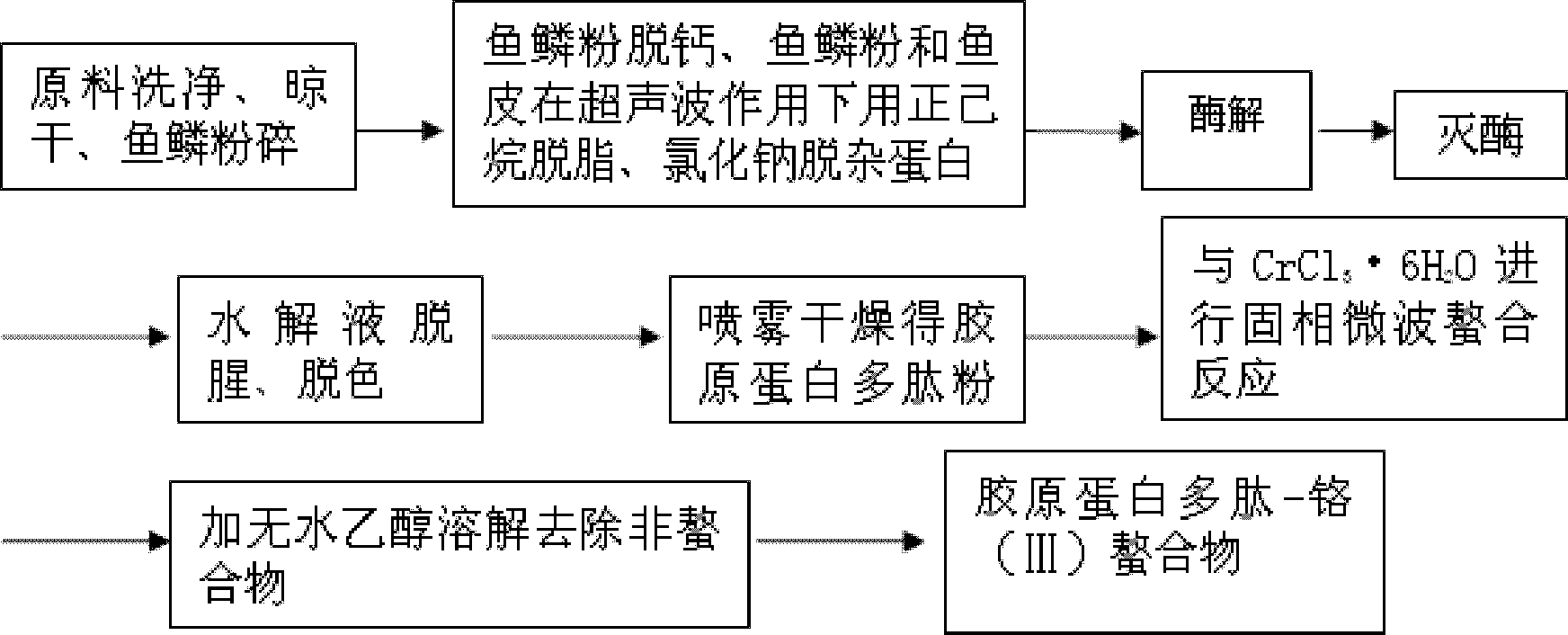

[0031] A processing method of red sea bream collagen polypeptide-chromium (III) chelate, the steps are:

[0032] (1) Raw material pretreatment and decalcification: take real sea bream as raw material, pretreatment such as slaughtering, viscera, head and tail removal, bone removal, etc., then wash the skin and scales and dry them, and crush the fish scales to make fish scale powder 10% lactic acid solution with a mass concentration according to the ratio of solid-liquid mass ratio of 1:15, soaking fish scale powder at normal temperature for 25min;

[0033] (2) Degreasing and de-impurity protein: the fish scale powder and fish skin are degreased with n-hexane under the condition that the ultrasonic frequency is 25kHz, the ultrasonic electric power is 250W, and the mass ratio of solid to liquid is 1:2, and the treatment time is 2h; Then be 25kHz at ultrasonic frequency, under the ultrasonic action of 250W with mass concentration be that 1% sodium chloride carries out impurity rem...

Embodiment 2

[0038] A processing method of red sea bream collagen polypeptide-chromium (III) chelate, the steps are:

[0039] (1) Raw material pretreatment and decalcification: take real sea bream as raw material, pretreatment such as slaughtering, viscera, head and tail removal, bone removal, etc., then wash the skin and scales and dry them, and crush the fish scales to make fish scale powder 15% lactic acid solution is used to soak the fish scale powder at normal temperature for 20 minutes according to the ratio of solid to liquid mass ratio of 1:20;

[0040] (2) Degreasing and impurity protein removal: degrease the fish scale powder and fish skin with n-hexane under the conditions of ultrasonic frequency of 50kHz, ultrasonic electric power of 500W, and material-to-liquid mass ratio of 1:3 respectively, and the treatment time is 3h ; then under the ultrasonic frequency of 50kHz, ultrasonic electric power is 500W with mass concentration of sodium chloride to degreasing fish scale powder, ...

Embodiment 3

[0045] A processing method of red sea bream collagen polypeptide-chromium (III) chelate, the steps are:

[0046] (1) Raw material pretreatment: using real sea bream as raw material, pretreatment such as slaughtering, viscera, head and tail, and bone removal, etc., then the fish skin and scales were washed and dried, and the fish scales were crushed to make fish scale powder. Soak fish scale powder at room temperature for 15 minutes in a solution with a concentration of 20% according to the ratio of 1:25;

[0047] (2) Degreasing and removing impurities: the fish scale powder and fish skin were degreased with n-hexane under the conditions of ultrasonic frequency of 80kHz, ultrasonic electric power of 800W, and solid-liquid mass ratio of 1:5, and the treatment time was 4h. then under the action of ultrasound that the ultrasonic frequency is 80kHz and the ultrasonic electric power is 800W, the fish scale powder and fish skin after degreasing are carried out to remove impurities re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com