Rare earth element-doped bismuth oxide photocatalyst and preparation method thereof

A technology of rare earth elements and photocatalysts, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of application limitations, band gap width, etc., and achieve good Effects of light absorption, improved adsorption capacity, and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

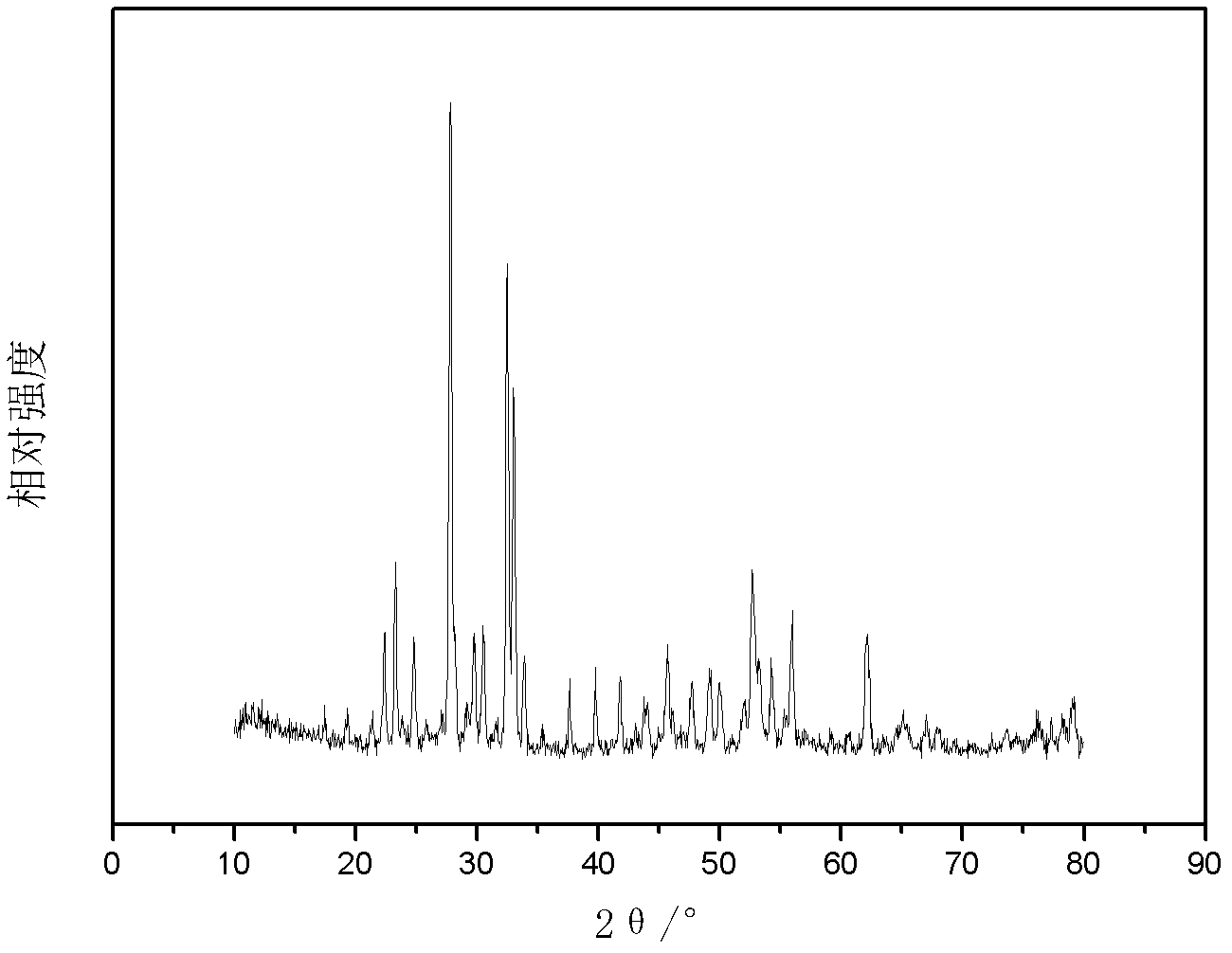

[0023] Weigh 0.5845g of ethylenediaminetetraacetic acid into 20ml of distilled water, add 0.75ml of ammonia water, heat and stir until dissolved, add 0.233g of bismuth oxide, 0.054g of cerium nitrate hexahydrate and 0.01g of ionic liquid 1-octyl-3- Methylimidazole tetrafluoroborate, heated in a water bath at 60°C, stirred until dissolved, formed a dry gel, crushed, put into a muffle furnace and burned at 400°C for 5 hours, and ground to obtain a bismuth oxide doped with cerium catalyst.

[0024] figure 2 The X-ray diffraction pattern of the bismuth oxide type catalyst doped with cerium is given. Figure 5 The ultraviolet-visible diffuse reflectance spectrum of bismuth oxide catalyst doped with cerium is given.

Embodiment 2

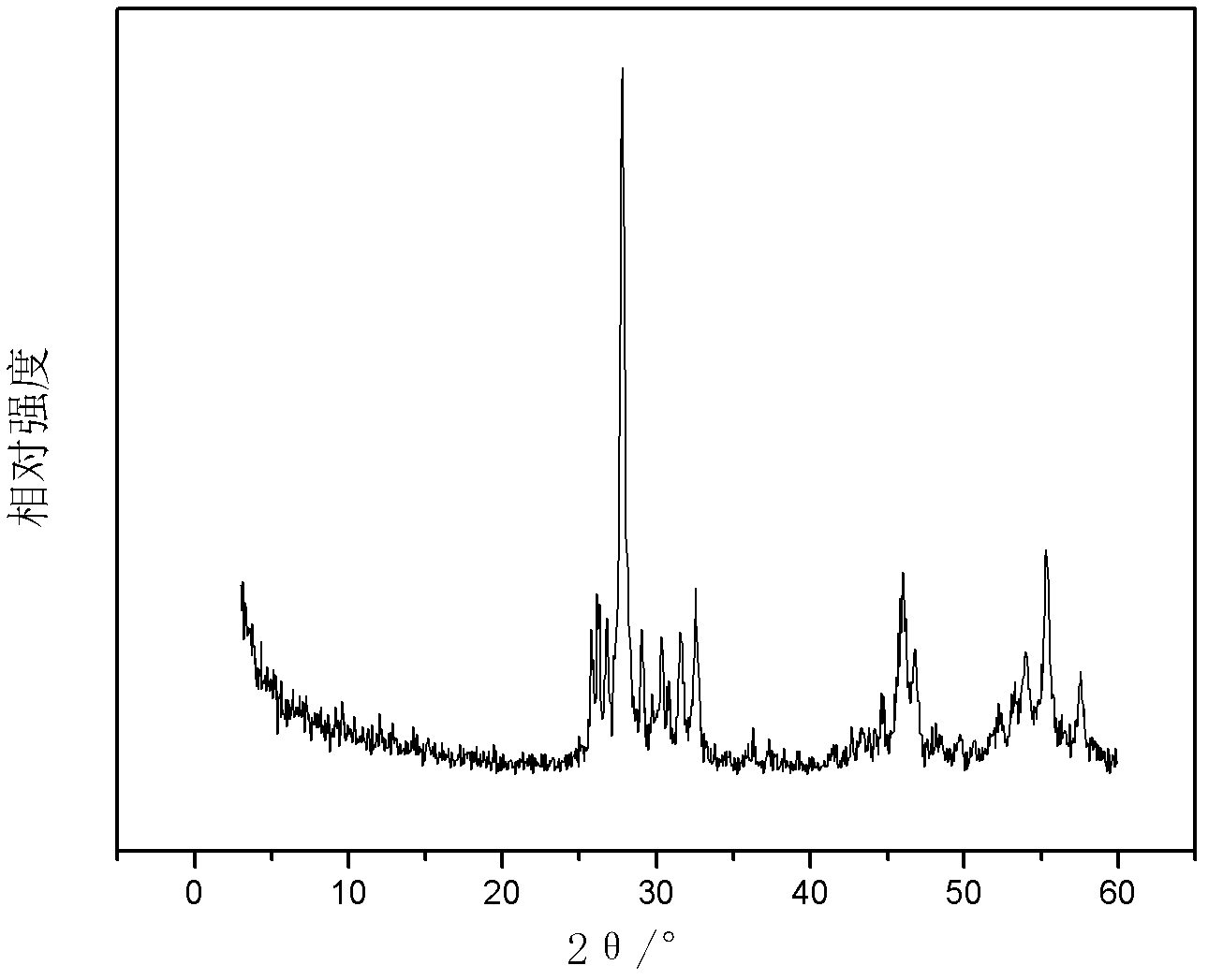

[0026] Weigh 0.5845g of ethylenediaminetetraacetic acid into 20ml of distilled water, add 0.75ml of ammonia water, heat and stir until dissolved, add 0.233g of bismuth oxide, 0.044g of europium oxide and 0.01g of ionic liquid 1-octyl-3-methyl Imidazolium tetrafluoroborate was heated in a water bath at 90°C, stirred until dissolved, formed into a xerogel, crushed, put into a muffle furnace and burned at 500°C for 3 hours, and ground to obtain a bismuth oxide catalyst doped with europium.

[0027] figure 1 An X-ray diffraction pattern of a bismuth oxide-type catalyst doped with europium is given. Figure 4 The ultraviolet-visible diffuse reflectance spectrum of the bismuth oxide type catalyst doped with europium is given.

Embodiment 3

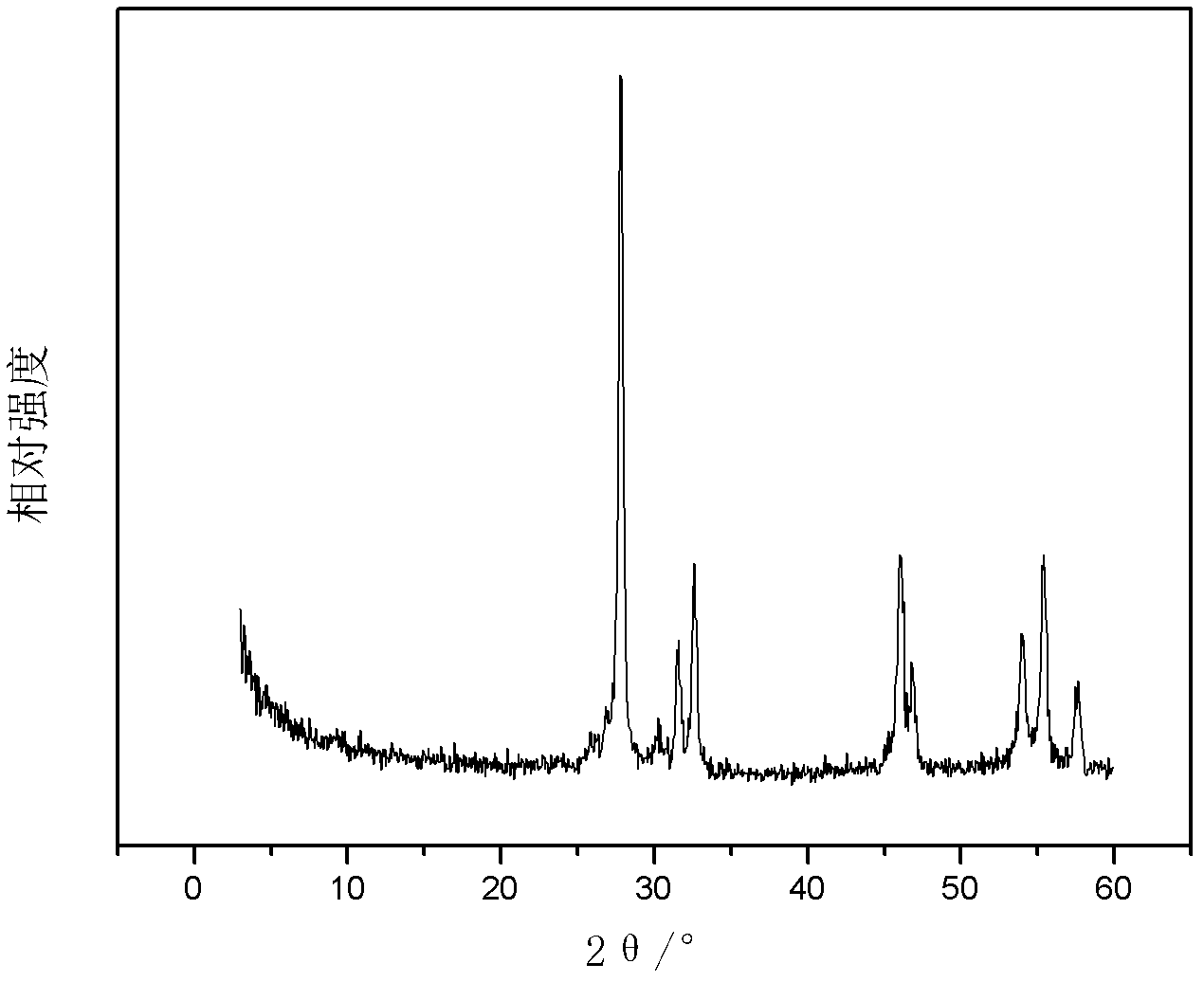

[0029] Weigh 0.5845g of ethylenediaminetetraacetic acid and add it to 20ml of distilled water, add 0.75ml of ammonia water, heat and stir until dissolved, add 0.233g of bismuth oxide, 0.015g of europium oxide, 0.036g of cerium nitrate hexahydrate and 0.01g of ionic liquid 1- Octyl-3-methylimidazolium tetrafluoroborate, heated in a water bath at 60°C, stirred until dissolved, formed a xerogel, crushed, put into a muffle furnace, burned at 400°C for 4 hours, and ground to obtain a composite blend Bismuth oxide type catalyst doped with europium and cerium.

[0030] image 3 The X-ray diffraction pattern of the bismuth oxide-type catalyst compositely doped with europium and cerium is given. Figure 6 The ultraviolet-visible diffuse reflectance spectrum of the compound-doped bismuth oxide catalyst is given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com