Preparation method of silver nanoring

A technology of silver nanometer and silver nitrate, applied in the field of preparation of silver nanorings, can solve the problems of rough preparation method, low yield, no detailed research, etc., and achieve the effects of unique scattering focusing effect, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

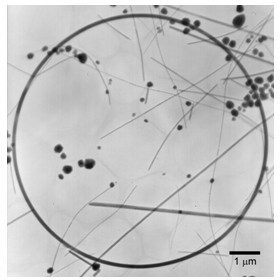

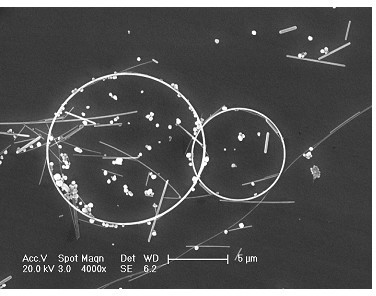

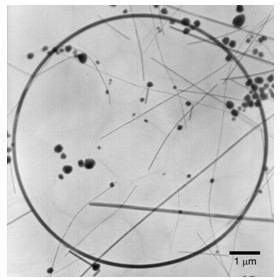

Image

Examples

preparation example Construction

[0026] Silver nano ring preparation method of the present invention, comprises the following steps:

[0027] (1) Heat ethylene glycol at high temperature for a period of time;

[0028] (2) Under the condition of stirring and heating, slowly add silver nitrate, polyvinylpyrrolidone and sodium bromide into the ethylene glycol heated at high temperature in a certain proportion;

[0029] (3) The solution continues to stir and heat for a certain period of time;

[0030] (4) After the reaction, the reaction product was centrifuged and washed with alcohol or acetone to obtain silver nanorings.

[0031] The heating temperature of the above-mentioned ethylene glycol is 150-190 degrees. Before adding other reactants, the ethylene glycol needs to be heated for a period of time. The heating time is 5 minutes to 1 hour. A specific scheme of the present invention is to heat for 1 hour. It can be stirred or not stirred during the early heating process. In the early heating process, ethyle...

Embodiment 1

[0039] 1. Weigh 48 mg of polyvinylpyrrolidone and 48 mg of silver nitrate; 2. Dissolve polyvinylpyrrolidone and silver nitrate in 3 mL of anhydrous ethylene glycol, and add 68 mg of polyvinylpyrrolidone-ethylene glycol solution μg of sodium bromide; 3. Add 5 mL of ethylene glycol to the three-mouthed sesame cake and heat it to 160 °C; 4. Mix polyvinylpyrrolidone-ethylene glycol solution and silver nitrate-ethylene glycol solution at a temperature of 160 °C Add dropwise at a rate of 0.5 mL / min from two ports of the three-port sesame cake, and stir at a rate of 1000 r / min until the reaction solution turns khaki, then take out the reaction solution, cool to room temperature, and centrifuge with ethanol to wash. The ethanol was collected to obtain a solution containing silver nanorings.

Embodiment 2

[0041] 1. Weigh 32 mg of polyvinylpyrrolidone and 48 mg of silver nitrate; 2. Dissolve polyvinylpyrrolidone and silver nitrate in 3 mL of anhydrous ethylene glycol, and add 45 mg of polyvinylpyrrolidone-ethylene glycol solution μg of sodium bromide; 3. Add 5 mL of ethylene glycol to the three-mouthed sesame cake and heat it to 150 °C; 4. Mix polyvinylpyrrolidone-ethylene glycol solution and silver nitrate-ethylene glycol solution at a temperature of 150 °C Add dropwise at a rate of 0.1 mL / min from two ports of the three-ported sesame cake, and stir at a rate of 600 r / min until the reaction solution turns khaki, then take out the reaction solution, cool to room temperature, and centrifuge with ethanol to wash. The ethanol was collected to obtain a solution containing silver nanorings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com