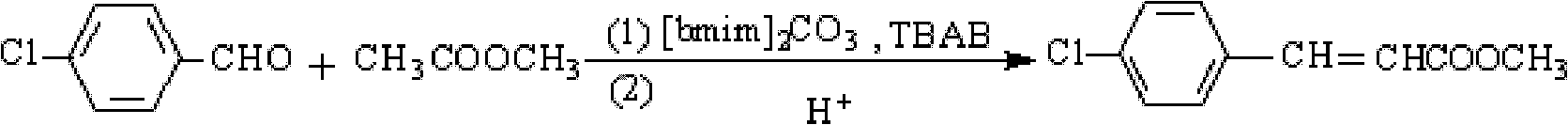

Preparation method of p-chlorine methyl cinnamate

A technology of methyl cinnamate and methyl acetate, applied in the field of preparation of methyl p-chlorocinnamate, can solve the problems of not meeting green production requirements, many side reactions, poor production conditions, etc., and achieves stable and reliable product quality, recycling The effect of convenient circulation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 0.06mol ionic liquid [bmim] 2 CO 3 , 0.2g (0.0006mol) TBAB and 3.7g (0.05mol) methyl acetate were added to a three-necked flask, and 7.4g (0.0525mol) p-chlorobenzaldehyde was added in 8 batches within 1.0h under stirring to keep the temperature at Below 5°C, after the addition is completed, let it react at room temperature for 2 hours, slowly add 5% by mass sulfuric acid dropwise to adjust the pH of the reaction solution between 6.5 and 7.2; filter, the filtrate obtained is the ionic liquid and the phase transfer catalyst TBAB The mixed solution is distilled under reduced pressure to remove water and saturated Na 2 CO 3 After the treatment, the solid is recycled and used, and the obtained solid is washed with hot water at 50-60°C, washed with ice water, and dried to obtain 8.7 g of methyl p-chlorocinnamate with a purity of 98.8% and a yield of 87.4% (calculated as methyl acetate).

Embodiment 2

[0028] 0.14mol ionic liquid [bmim] 2 CO 3 , 0.6g (0.002mol) TBAB and 7.4g (0.1mol) methyl acetate were added to a three-necked flask, and 15.5g (0.11mol) p-chlorobenzaldehyde was added in 8 batches within 1.0h under stirring to keep the temperature at 5 Below ℃, after the addition, let it react at room temperature for 3 hours, slowly add 5% by mass sulfuric acid dropwise to adjust the pH of the reaction solution between 6.5 and 7.2; filter, the filtrate obtained is a mixture of ionic liquid and phase transfer catalyst TBAB Liquid, remove water and saturated Na by distillation under reduced pressure 2 CO 3 After treatment, the solid is recycled and used, and the obtained solid is washed with hot water at 50-60°C, washed with ice water, and dried to obtain 17.5 g of methyl p-chlorocinnamate with a purity of 99.1% and a yield of 88.2% (calculated as methyl acetate).

Embodiment 3

[0030] 0.24mol ionic liquid [bmim] 2 CO 3 , 1.5g (0.0046mol) TBAB and 11.1g (0.15mol) methyl acetate were added to a three-necked flask, and 25.3g (0.18mol) p-chlorobenzaldehyde was added in 9 batches under stirring within 1.5h to keep the temperature at 5 Below ℃, after the addition, let it react at room temperature for 3.5h, slowly add 5% by mass sulfuric acid dropwise to adjust the pH of the reaction solution between 6.5 and 7.2; filter, the filtrate obtained is the ionic liquid and the phase transfer catalyst TBAB The mixed solution is distilled under reduced pressure to remove water and saturated Na 2 CO 3 After treatment, the solid is recycled and used, and the obtained solid is washed with hot water at 50-60°C, washed with ice water, and dried to obtain 27.3 g of methyl p-chlorocinnamate, with a purity of 99.4% and a yield of 92.0% (calculated as methyl acetate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com