Device and method for preparing DL-methionine salt

A technology for a methionine salt and a preparation device, which is applied in the field of improved preparation devices, can solve the problems of a decrease in the yield of DL-methionine salt, degradation of organic raw materials, polymerization, difficult control of reaction conditions, etc. , the effect of reducing by-products and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

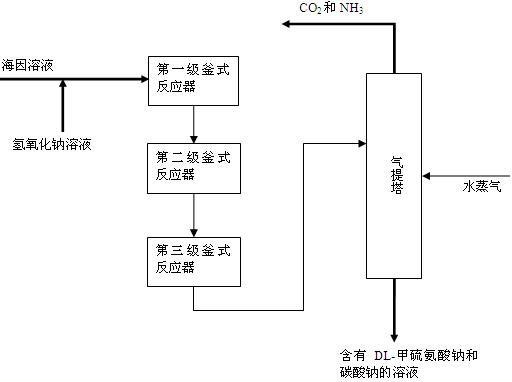

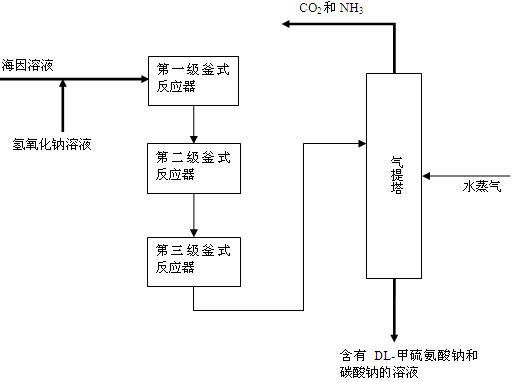

[0022] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0023] The schematic diagram of the device of the present invention is as figure 1 shown. The preparation device of DL-methionine salt comprises three stages of tank reactors in series and a stripping tower, wherein the discharge port of the first stage reactor is communicated with the feed port of the second stage reactor, and the second The discharge port of the first-stage tank reactor communicates with the feed port of the third-stage tank reactor, and the discharge port of the third-stage tank reactor communicates with the feed port of the stripping tower.

[0024] As a preferred embodiment of the device of the present invention, the top of the stripping tower is also provided with a gas-liquid separator; There is a pressure relief valve.

[0025] The schematic flow chart of the method of the present invention is as figure 1 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com