Thickened oil nanometer viscosity reducer and preparation method thereof

A viscosity reducer, nanotechnology, applied in the field of polymer nanomaterial preparation, to achieve the effect of wide application range, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

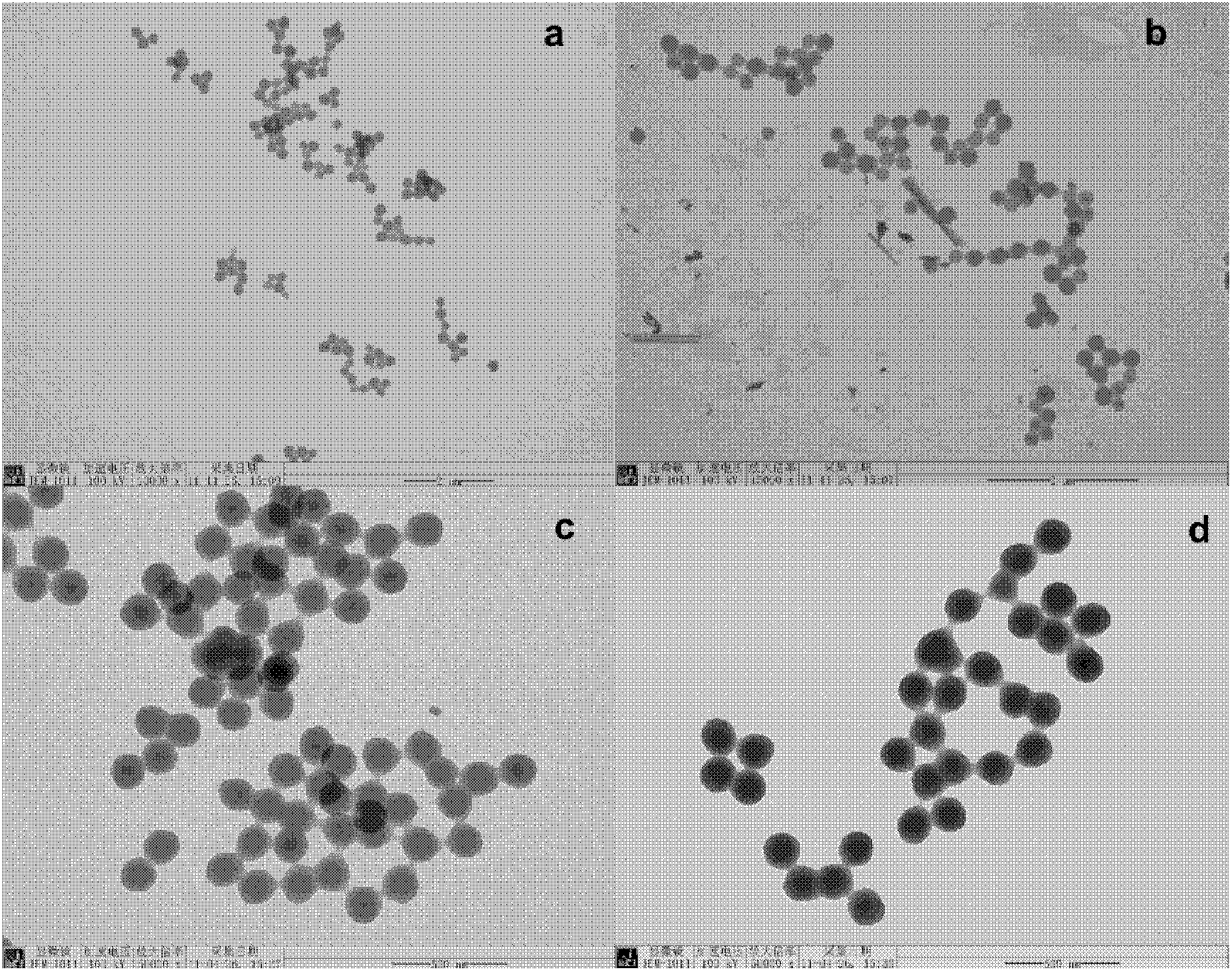

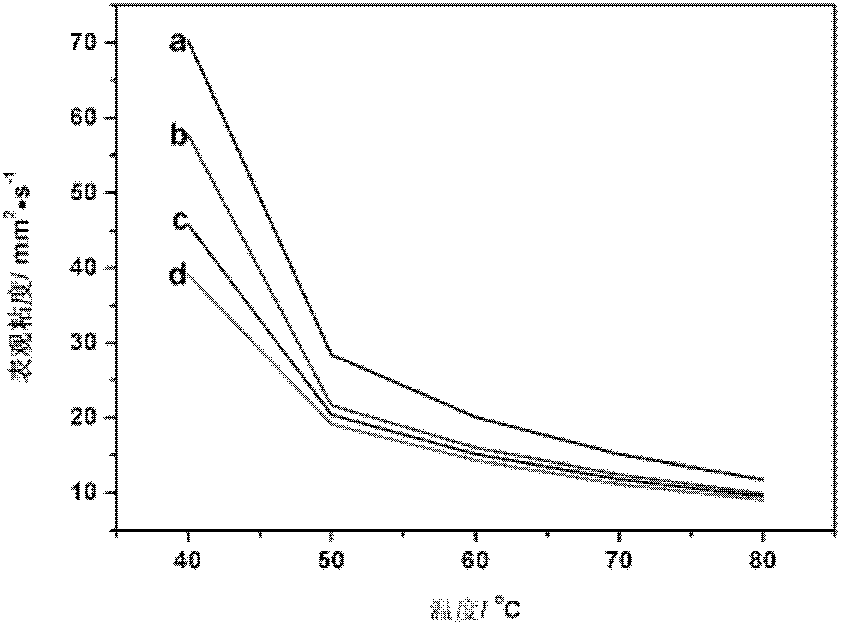

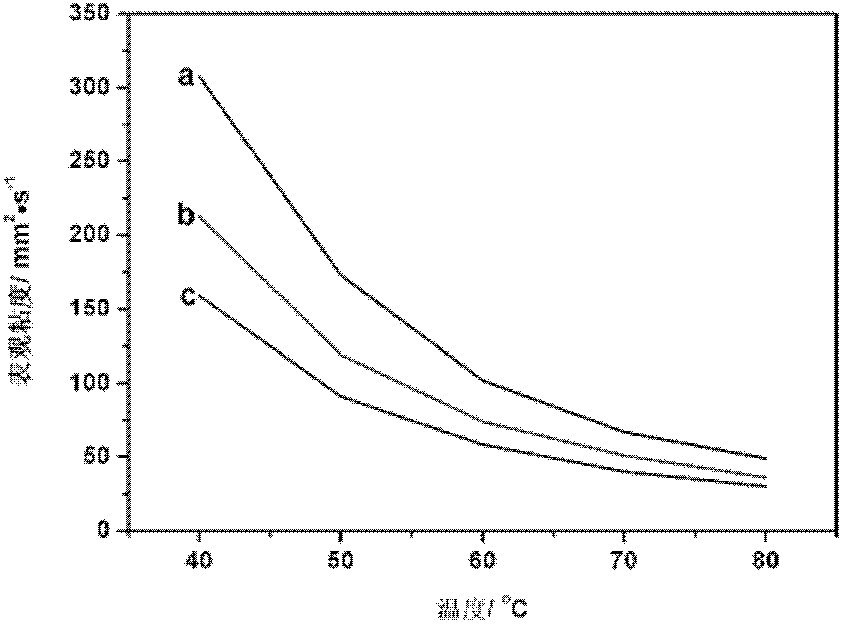

Image

Examples

Embodiment 1

[0030] The preparation method of nano lauryl methacrylate homopolymer, the steps are as follows:

[0031] (1) Measure 30 ml of methyl methacrylate, add it to 100 ml of water, blow in nitrogen, add 0.3 g of benzoyl peroxide, and heat to 100°C for 5 hours.

[0032] (2) The obtained reaction solution was centrifuged or evaporated at 50°C to remove water, and then vacuum-dried at 60°C for 12 hours.

[0033] (3) Weigh 5 grams of nano-methyl methacrylate powder and 5 grams of dodecanol in 50 ml of dimethylformamide, add 1% sodium hydroxide and react at 180°C for 7 hours. Cool to room temperature.

[0034] (4) Add the cooled solution to a certain amount of water, filter, and then vacuum-dry at 80°C for 12h.

Embodiment 2

[0035] Embodiment 2: the preparation method of nano-tetradecyl methacrylate homopolymer, step is the same as example 1, difference is to replace lauryl alcohol with myristyl alcohol.

Embodiment 3

[0036] Embodiment 3: the preparation method of nano-hexadecyl methacrylate homopolymer, step is the same as example 1, difference is to replace lauryl alcohol with cetyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com