Near ultraviolet stimulated borophosphate white light fluorescent powder and preparation method

A borophosphate and phosphor technology, which is applied to the luminescent materials for blue LEDs and the field of violet light, can solve the problems that the luminous efficiency does not reach practical application value and the synthesis temperature of silicate-based phosphors is high, and achieves easy operation and simple preparation method. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

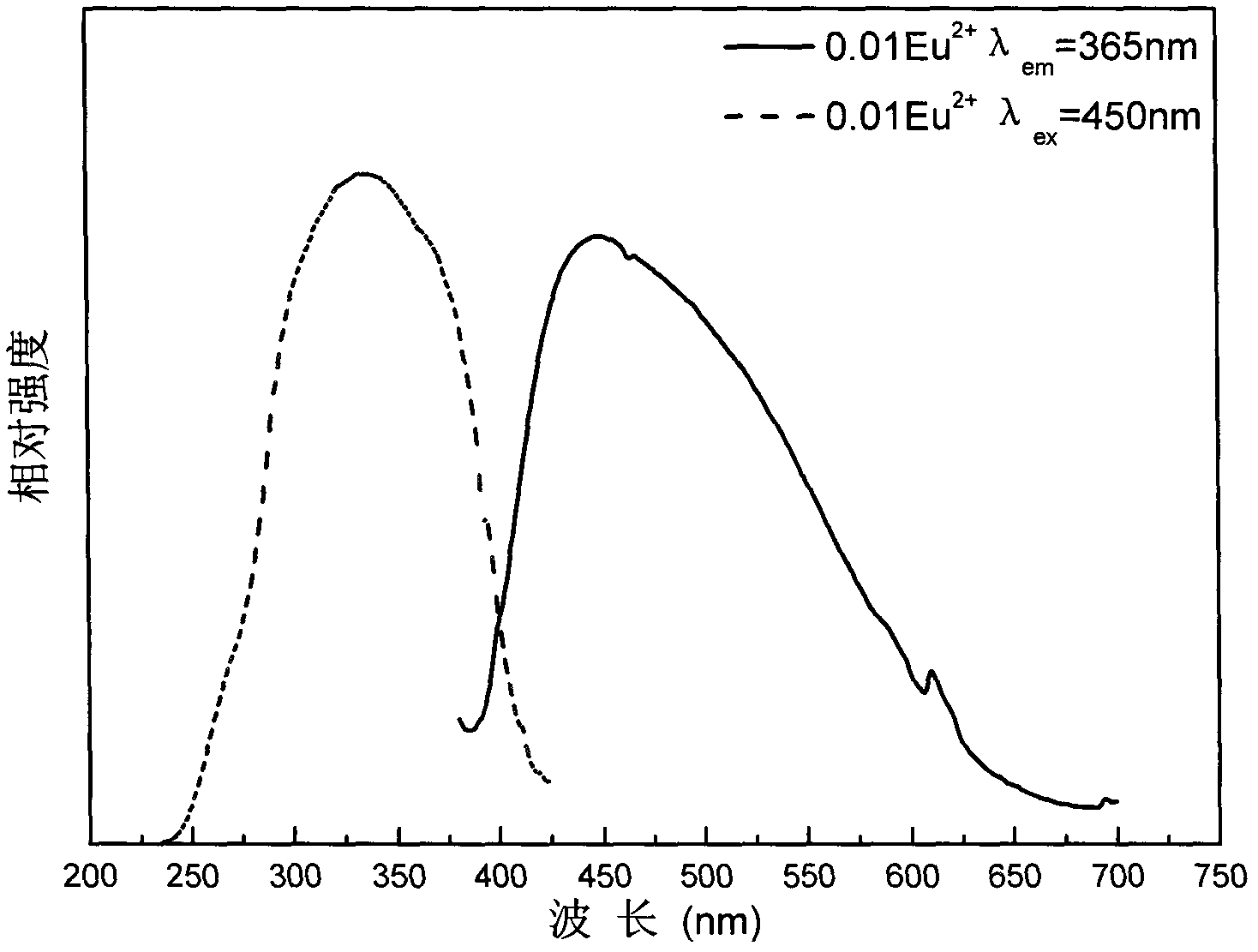

[0020] Example 1: KBa 0 99 BP 2 o 8 :0.01Eu 2+ Phosphor powder preparation

[0021] Potassium carbonate (K 2 CO 3 ) 0.544g, boric acid (H 3 BO 3 ) 0.486g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.81g, barium carbonate (BaCO 3 ) 1.55g, europium trioxide (Eu 2 o 3 ) 0.0277g, after the above-mentioned raw materials are fully ground and mixed in an agate mortar, they are molded into Φ20 thin slices on a tablet machine, put into an alumina crucible, and first burned at 600°C for 3 hours, then taken out and ground, Then put it into an alumina crucible. Before heating, the air in the furnace should be driven out by vacuuming, and then burned at 900°C for 3 hours under a carbon monoxide atmosphere. Wash and finally get the sample. The sample is excited under 365nm ultraviolet light, which mainly emits blue and white light. The room temperature excitation and emission spectra of this phosphor are shown in figure 1 .

Embodiment 2

[0022] Example 2: KBa 0.98 BP 2 o 8 :0.02Eu 2+ Phosphor powder preparation

[0023] Potassium carbonate (K 2 CO 3 ) 0.544g, boric acid (H 3 BO 3 ) 0.486g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.81g, barium carbonate (BaCO 3 ) 1.55g, europium trioxide (Eu 2 o 3 ) 0.0553g, the above raw materials were fully ground and mixed in an agate mortar, pressed into thin slices on a tablet machine, put into an alumina crucible, first burned at 600°C for 3 hours, then taken out and ground, and then loaded Put it into an alumina crucible, remove the air in the furnace by vacuuming before heating, then burn at 900°C for 3 hours under a carbon monoxide atmosphere, grind evenly after cooling, then crush and sieve, and wash with water and ethanol respectively, Finally got the sample. The sample is excited under 365nm ultraviolet light, which mainly emits white light.

Embodiment 3

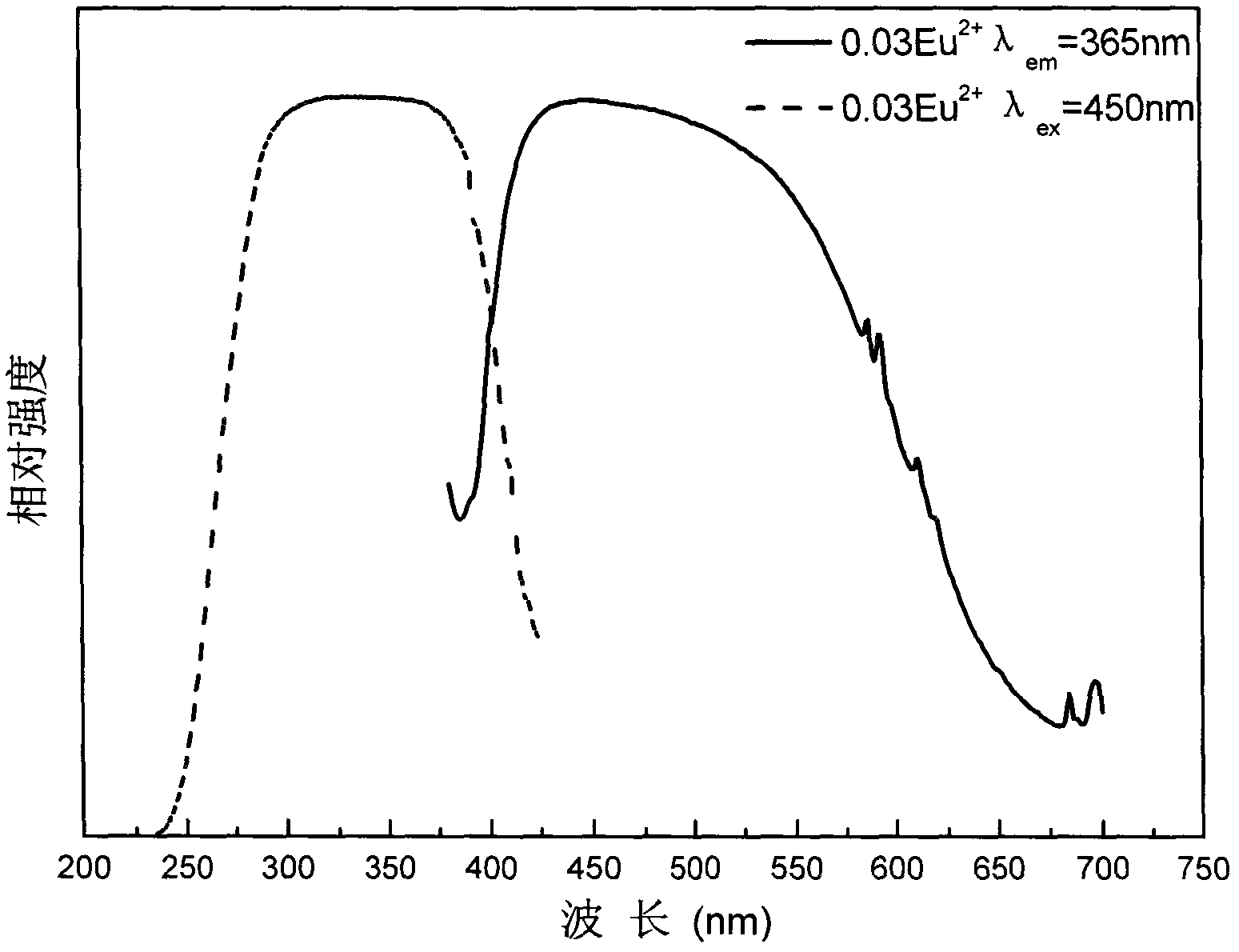

[0024] Example 3: KBa 0.97 BP 2 o 8 :0.03Eu 2+ Phosphor powder preparation

[0025] Potassium carbonate (K 2 CO 3 ) 0.544g, boric acid (H 3 BO 3 ) 0.486g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.81g, barium carbonate (BaCO 3 ) 1.55g, europium trioxide (Eu 2 o 3 ) 0.0829g, the above raw materials were fully ground and mixed in an agate mortar, pressed into thin slices on a tablet machine, put into an alumina crucible, first burned at 600°C for 3 hours, then taken out and ground, and then loaded Put it into an alumina crucible, remove the air in the furnace by vacuuming before heating, then burn at 900°C for 3 hours under a carbon monoxide atmosphere, grind evenly after cooling, then crush and sieve, and wash with water and ethanol respectively, Finally got the sample. The sample is excited under 365nm ultraviolet light, which mainly emits white light. The room temperature excitation and emission spectra of this phosphor are shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com