Preparation method of laser irradiation in-situ self-generated Al-Fe-Si ternary ceramic/Fe composite coating

A technology of al-fe-si and ternary ceramics, which is applied in coating, metal material coating process, etc., can solve the problem of poor wettability between reinforcement and coating substrate, poor bonding between coating and substrate, and poor interface bonding, etc. problems, to achieve good application prospects and economic significance, clean interface, and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

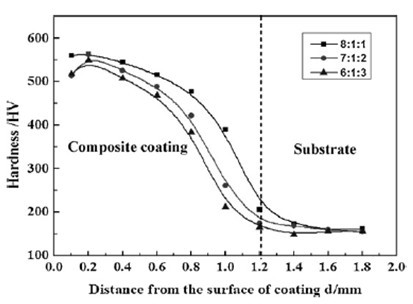

Embodiment 1

[0017] First, use a sandblasting machine to sandblast the surface of the substrate Q235 steel to remove the rust layer and oxides on the surface, and obtain a surface with a large surface roughness; clean the surface of the roughened Q235 steel with acetone solution until the surface Clean without oil stains, etc.; then air dry naturally for later use. Put 200-mesh Fe powder, 200-mesh Al powder and 200-mesh Si powder into the mixer at a ratio of 6:1:3 and mix for 3 hours, so that Fe powder, Al powder and Si powder are fully mixed and prepared into Fe-Al- Si composite powder. Put the Q235 steel on the laser workbench, set the prefabricated composite powder on the substrate, and scan with the laser. The process parameters of the laser are: the laser power is 1600W, the scanning speed is 400mm / min, and the spot diameter is 4mm.

Embodiment 2

[0019] First, use a sandblasting machine to sandblast the surface of the substrate Q235 steel to remove the rust layer and oxides on the surface, and obtain a surface with a large surface roughness; clean the surface of the roughened Q235 steel with acetone solution until the surface Clean without oil stains, etc.; then air dry naturally for later use. Put 200-mesh Fe powder, 200-mesh Al powder and 200-mesh Si powder into the mixer at a ratio of 8:1:1 and mix for 3 hours, so that Fe powder, Al powder and Si powder are fully mixed and prepared into Fe-Al- Si composite powder. Put the Q235 steel on the laser workbench, set the prefabricated composite powder on the substrate, and scan with the laser. The process parameters of the laser are: the laser power is 1600W, the scanning speed is 400mm / min, and the spot diameter is 4mm.

Embodiment 3

[0021] First, use a sandblasting machine to sandblast the surface of the substrate Q235 steel to remove the rust layer and oxides on the surface, and obtain a surface with a large surface roughness; clean the surface of the roughened Q235 steel with acetone solution until the surface Clean without oil stains, etc.; then air dry naturally for later use. Put 200-mesh Fe powder, 200-mesh Al powder and 200-mesh Si powder into the mixer at a ratio of 7:1:2 and mix for 3 hours, so that Fe powder, Al powder and Si powder are fully mixed and prepared into Fe-Al- Si composite powder. Put the Q235 steel on the laser workbench, set the prefabricated composite powder on the substrate, and scan with the laser. The process parameters of the laser are: the laser power is 1600W, the scanning speed is 400mm / min, and the spot diameter is 4mm.

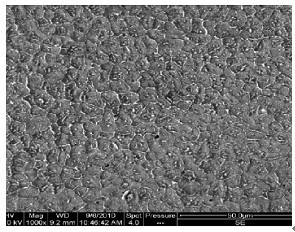

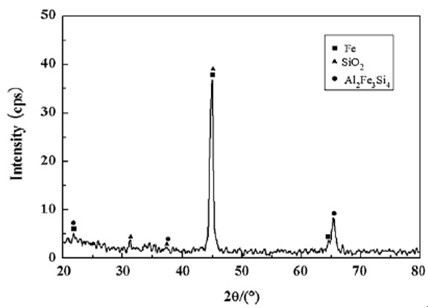

[0022] figure 1 For the microstructure of the composite coating prepared in Example 1, it can be seen from the figure that the coating surface is smoo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com